In the realm of electrical engineering and safety, one name that stands out prominently is that of China Molded Case Circuit Breaker OEM Manufacturers. With a history steeped in innovation and a commitment to excellence, these manufacturers have consistently led the industry in providing top-notch circuit breaker solutions. In this article, we will delve into the world of China Molded Case Circuit Breaker OEM Manufacturers, exploring their history, products, and the pivotal role they play in ensuring electrical safety.

A Legacy of Innovation

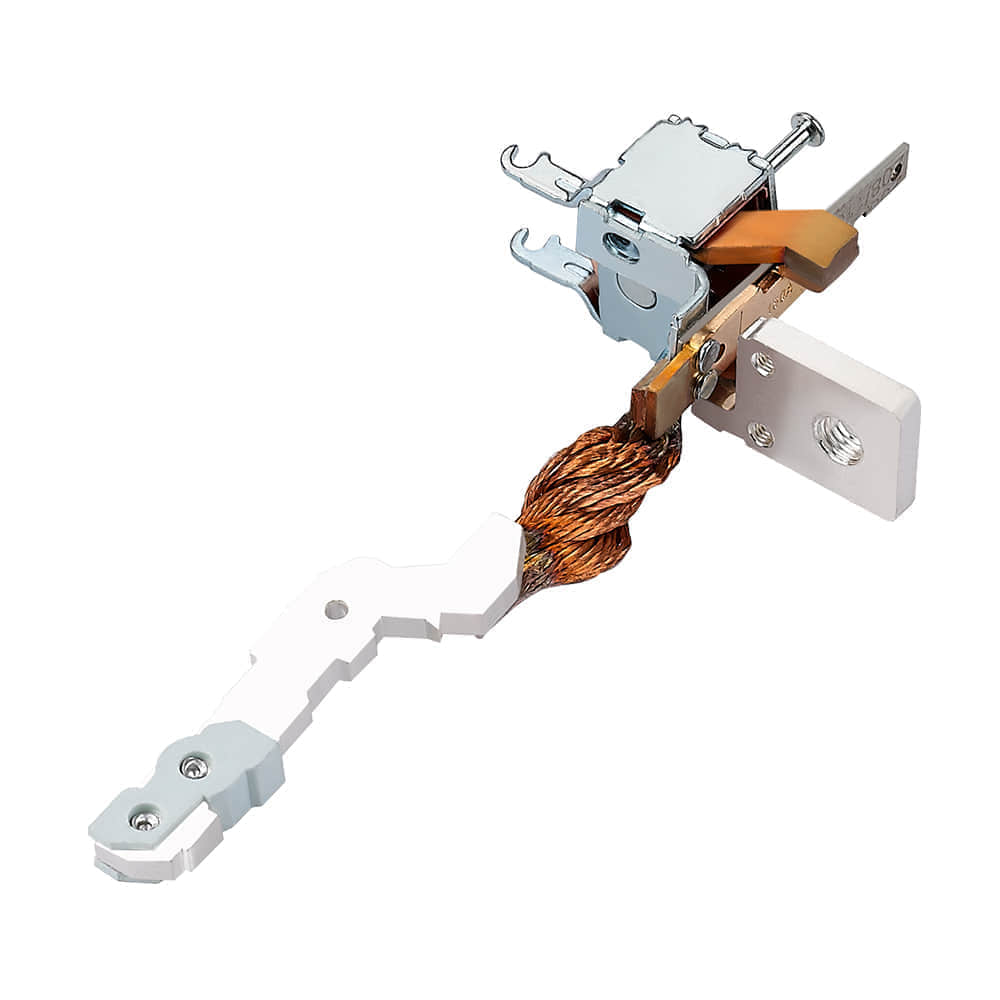

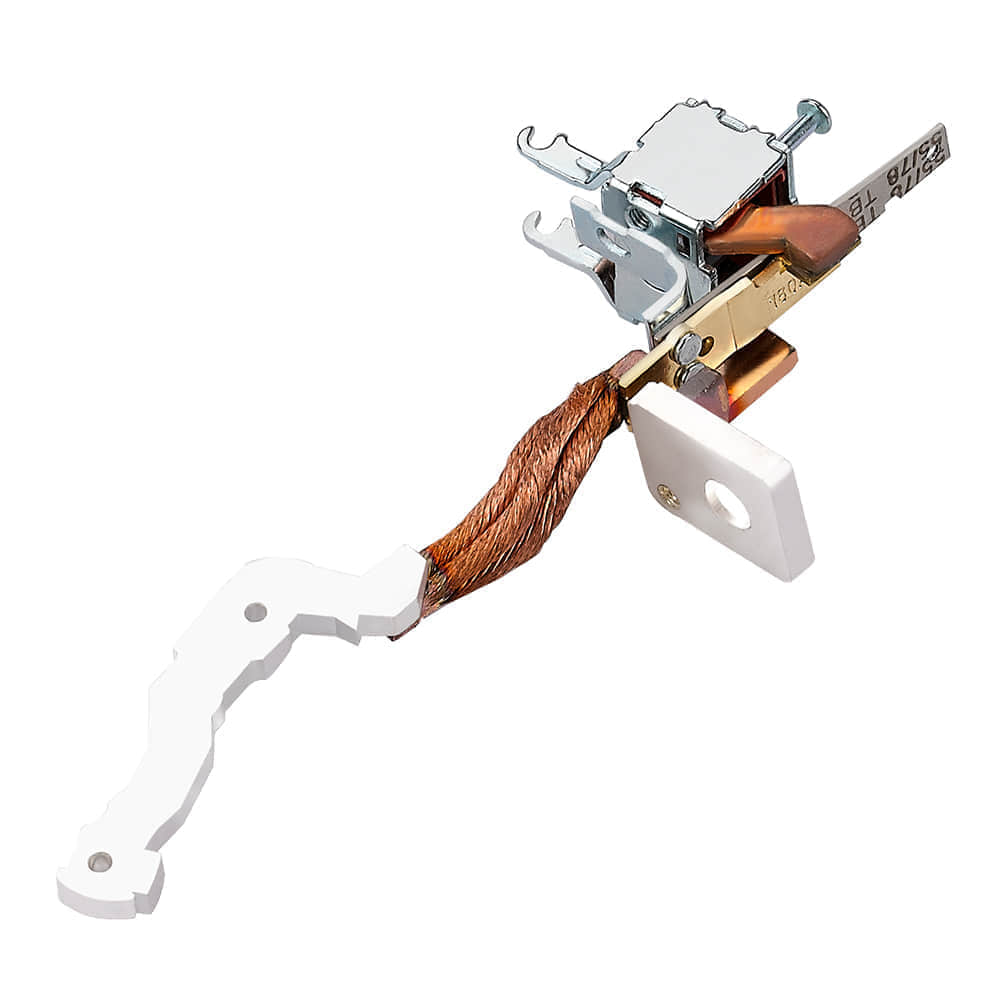

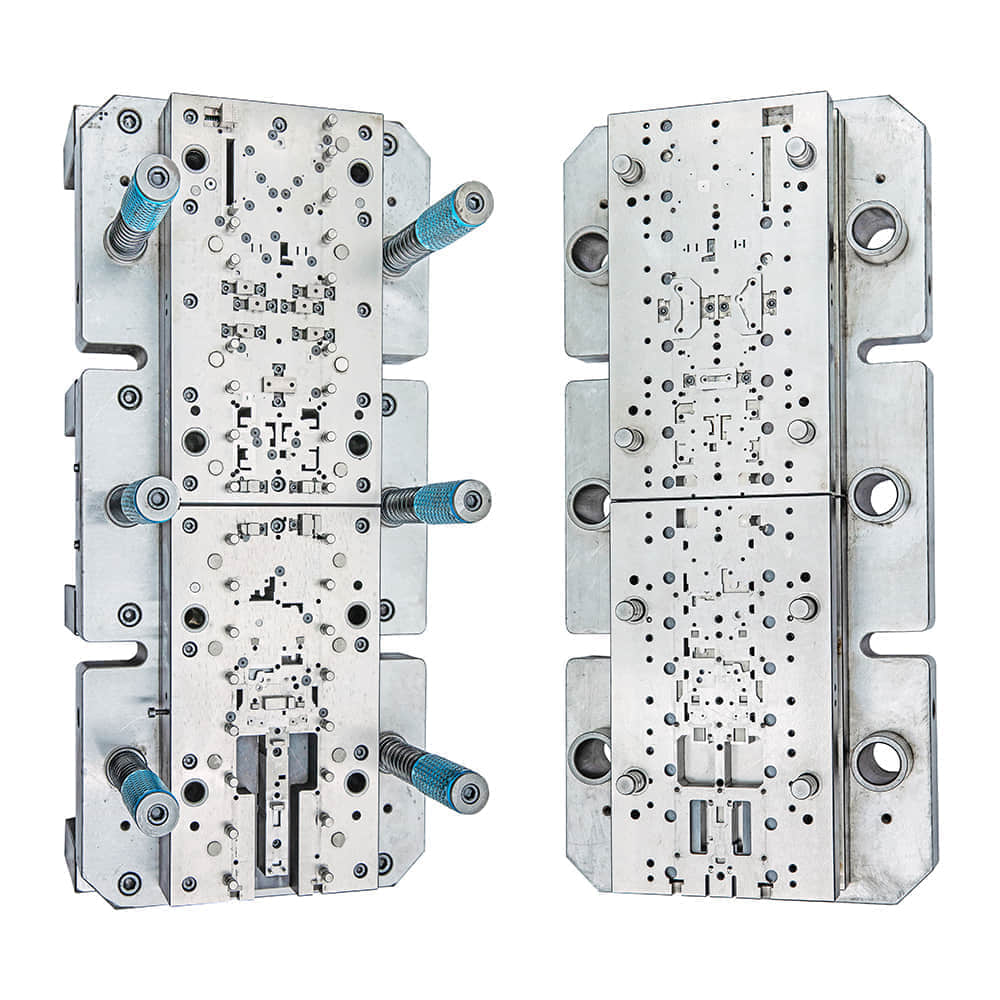

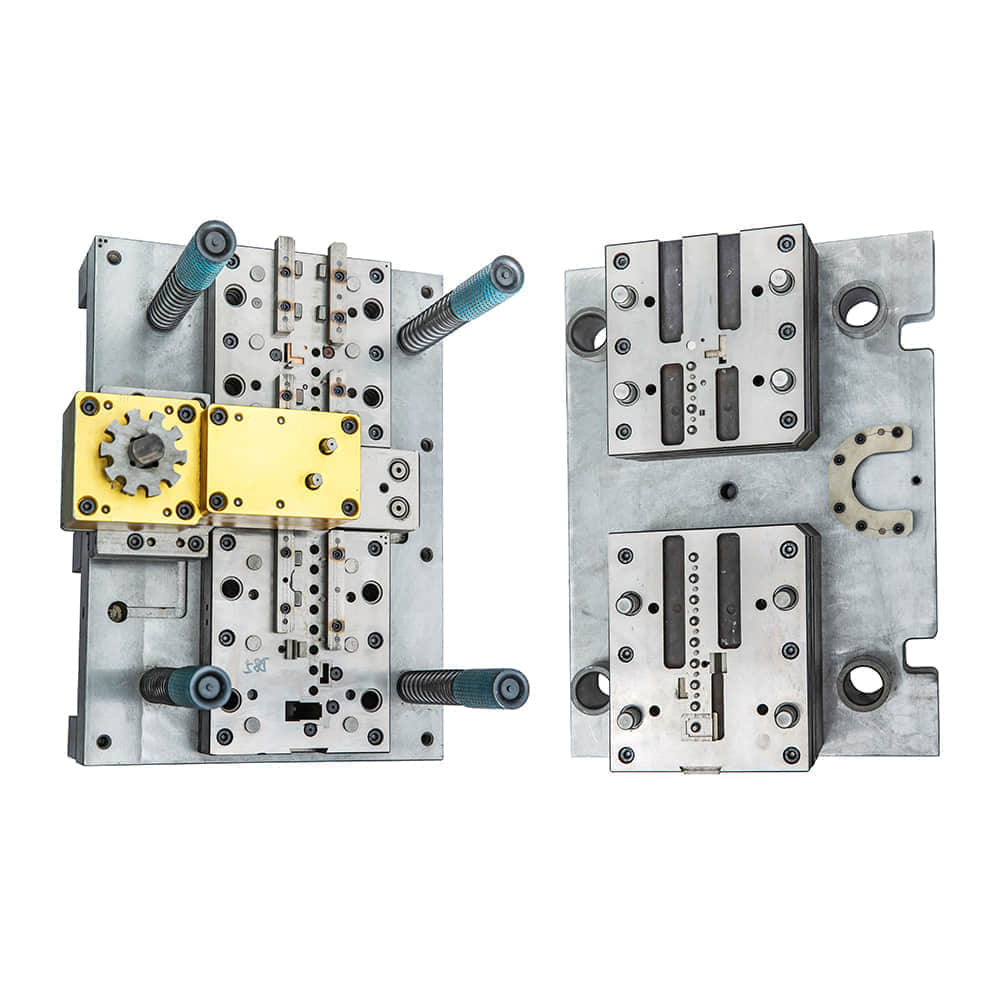

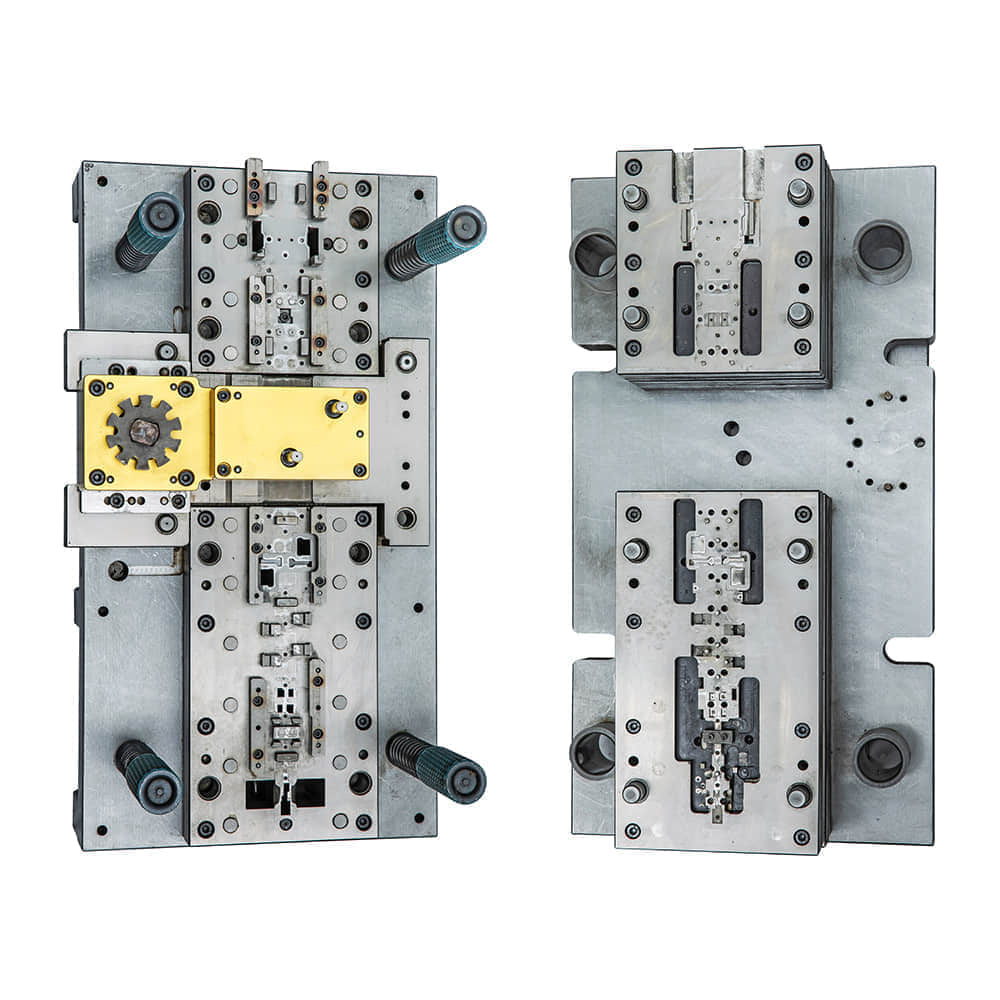

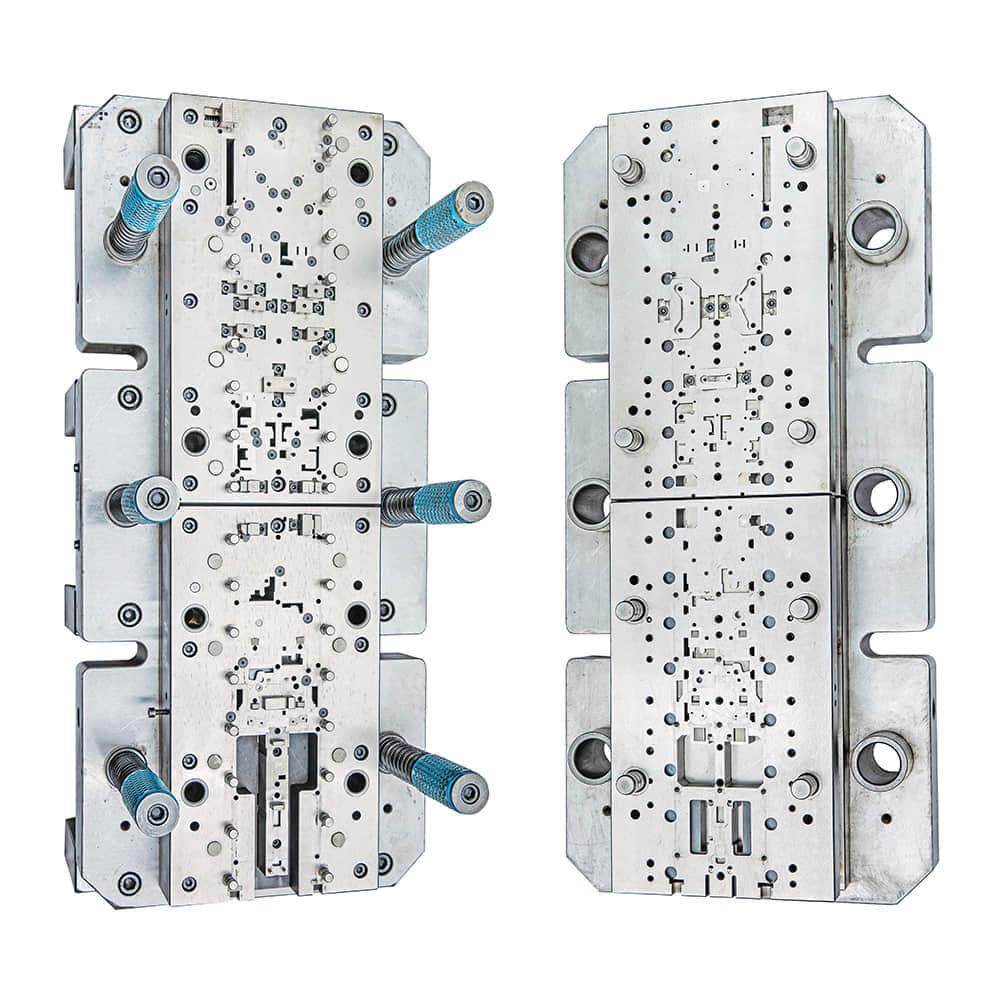

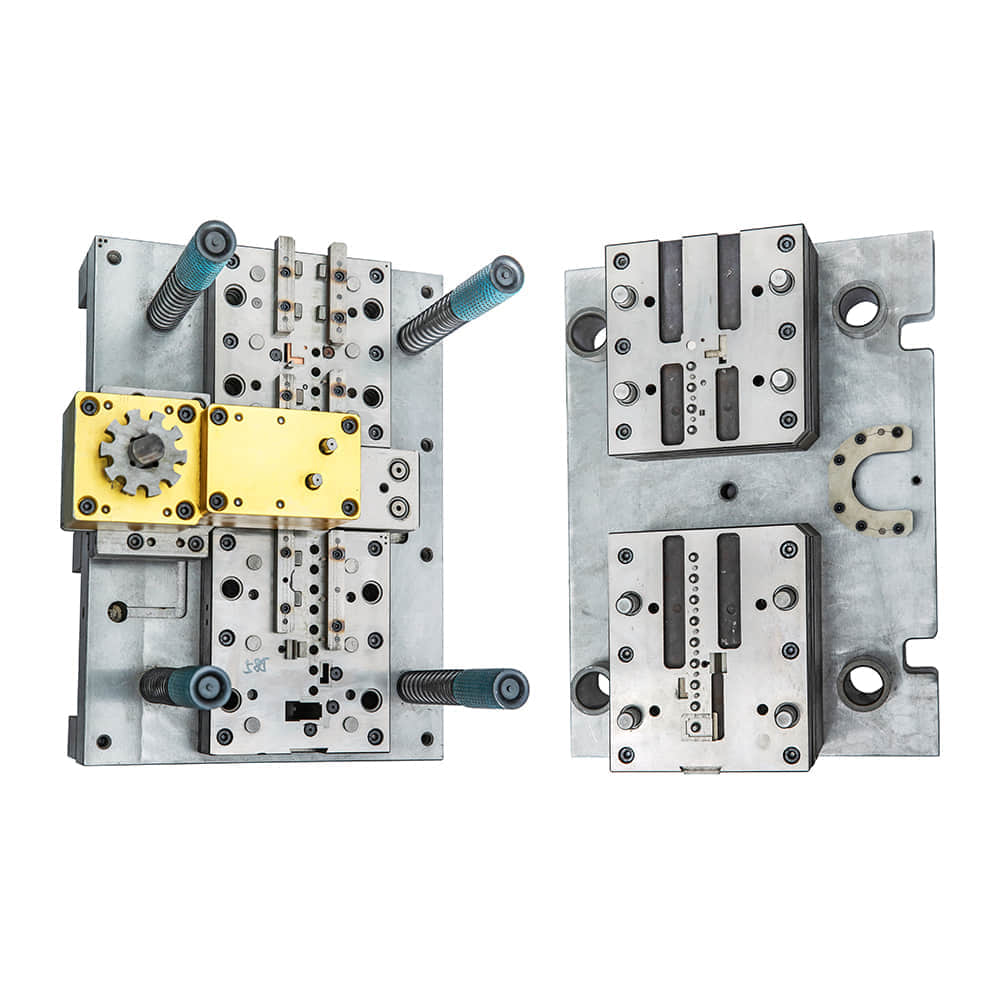

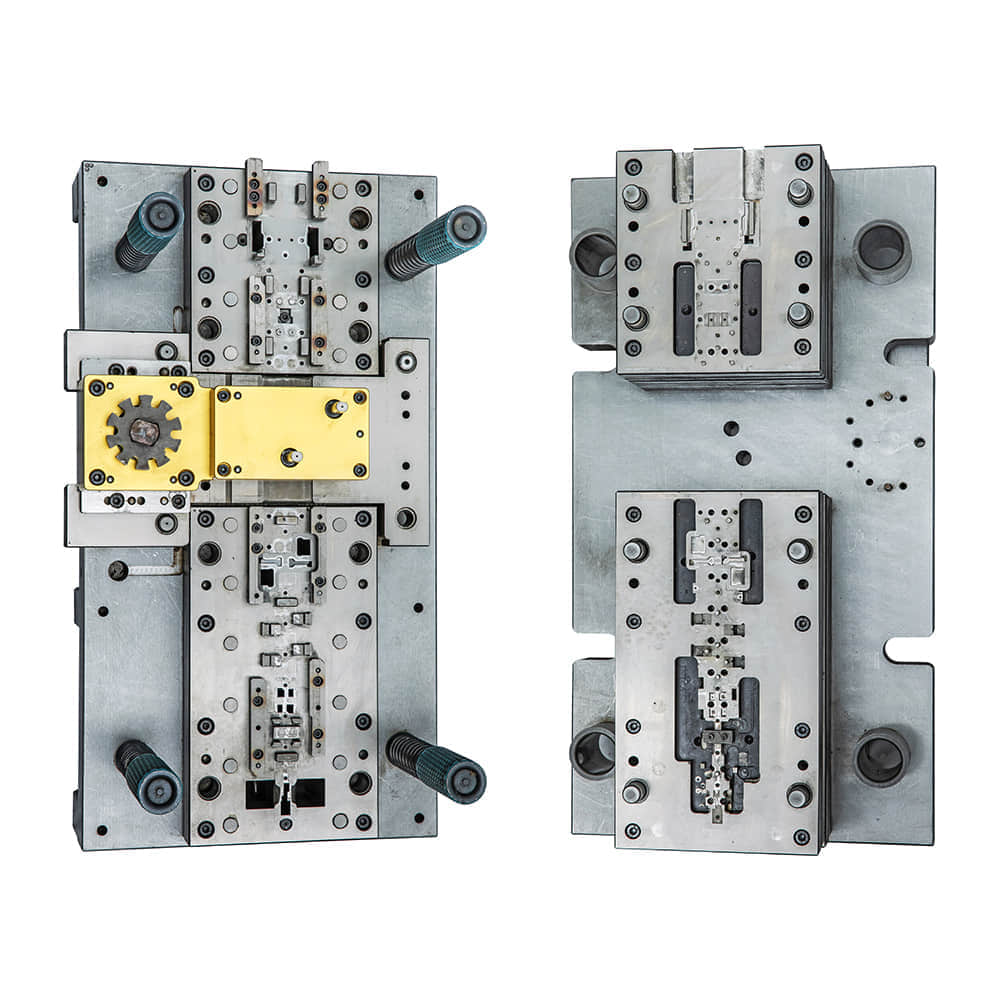

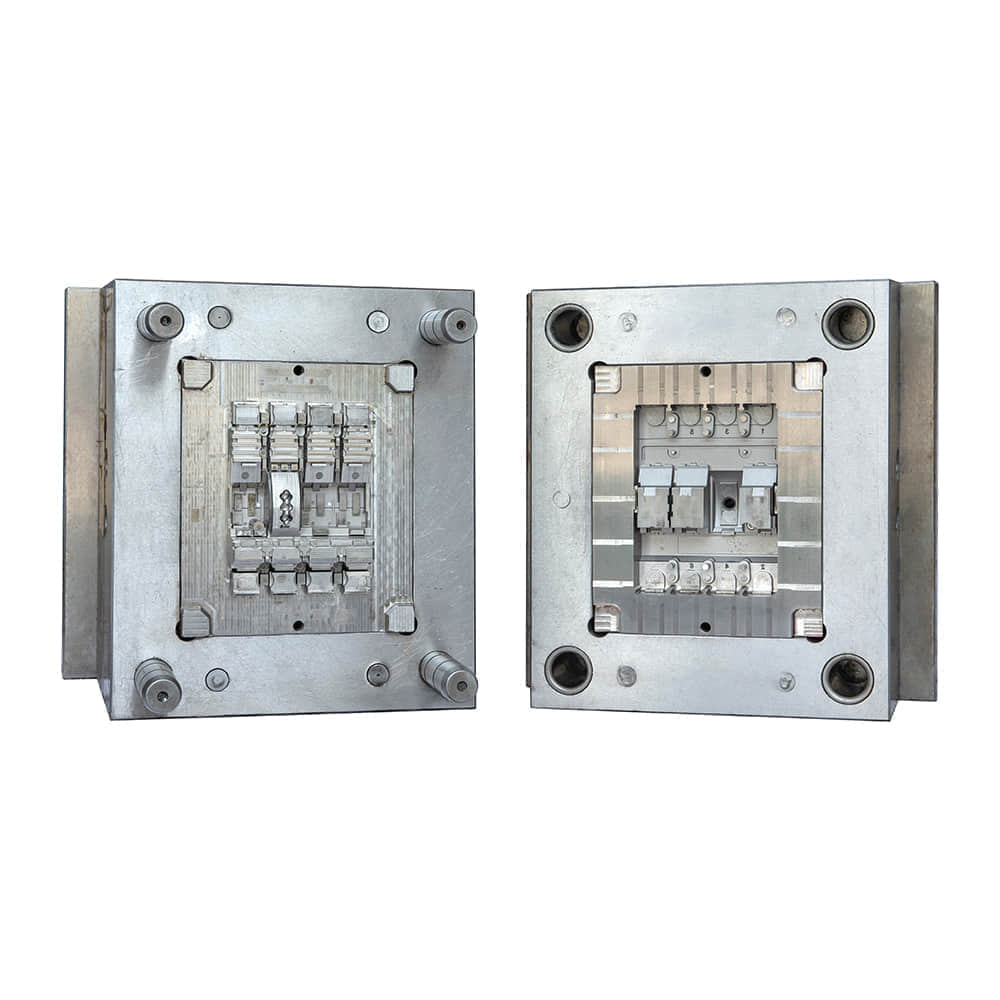

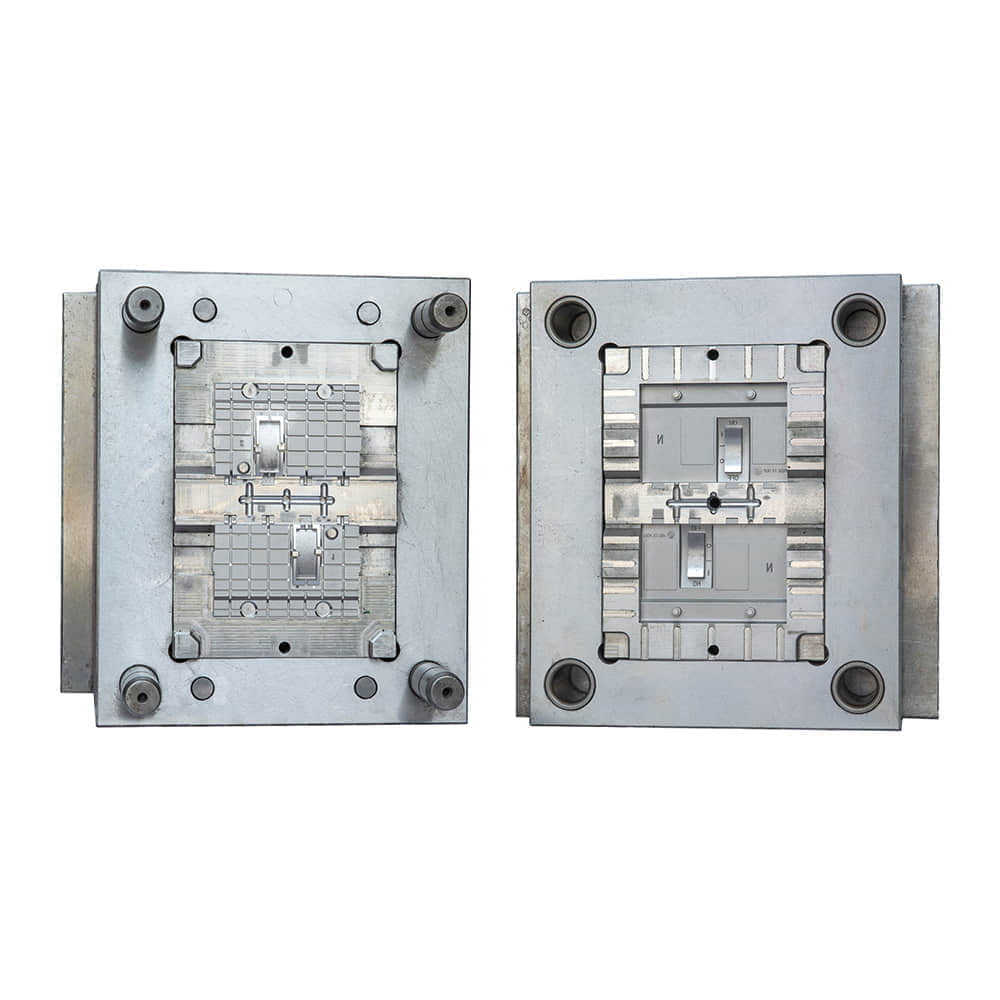

China Molded Case Circuit Breaker OEM Manufacturers have a rich legacy of innovation that dates back several decades. Their journey began with a vision to revolutionize the electrical safety landscape, and over the years, they have exceeded expectations with their groundbreaking solutions. They have consistently pushed the boundaries of what is possible in the field of electrical circuit protection, setting new industry standards along the way. Cutting-Edge Products At the heart of China Molded Case Circuit Breaker OEM Manufacturers’ success lies their range of cutting-edge products. These manufacturers offer a diverse portfolio of molded case circuit breakers that cater to a wide array of industrial and commercial applications. Whether it’s safeguarding critical infrastructure or ensuring uninterrupted power supply in residential settings, their products are designed to meet the most demanding requirements. One standout feature of their circuit breakers is their reliability. These devices are engineered to provide faultless performance under various operating conditions. They incorporate advanced technologies such as thermal-magnetic trip units and electronic trip units to quickly and accurately detect and respond to overcurrents and short circuits, preventing electrical fires and equipment damage. Global Reach China Molded Case Circuit Breaker OEM Manufacturers have expanded their reach far beyond their home market. Their commitment to quality and safety has earned them a stellar reputation on the global stage. They export their products to countries across the world, further solidifying their position as an industry leader. Their adherence to international standards and certifications ensures that their circuit breakers are trusted and used in diverse electrical systems worldwide. Innovation and Sustainability In an era marked by increasing environmental concerns, China Molded Case Circuit Breaker OEM Manufacturers have also taken significant strides towards sustainability. They understand the importance of reducing the environmental footprint of their products and have integrated eco-friendly materials and manufacturing processes into their operations. This commitment to sustainability not only benefits the planet but also aligns with the evolving needs of environmentally conscious customers. Customer-Centric Approach One of the distinguishing factors that set China Molded Case Circuit Breaker OEM Manufacturers apart is their unwavering commitment to their customers. They prioritize understanding the unique needs of each customer and providing tailored solutions. This customer-centric approach has earned them the loyalty and trust of clients worldwide. Conclusion China Molded Case Circuit Breaker OEM Manufacturers have consistently demonstrated their prowess in the realm of electrical safety. With a legacy of innovation, cutting-edge products, a global presence, and a commitment to sustainability and customer satisfaction, they have rightfully earned their place as leaders in the industry. As the world continues to rely on electricity for an ever-expanding range of applications, the role of these manufacturers in ensuring electrical safety remains pivotal, and their future promises to be as bright as their illustrious past.