Metal stamping is a versatile and widely used manufacturing process that plays a crucial role in various industries. Metal stamping parts manufacturers are the unsung heroes behind many everyday products we use. In this article, we will delve into the world of metal stamping parts manufacturers, exploring their significance, processes, and applications.

The Significance of Metal Stamping Parts Manufacturers

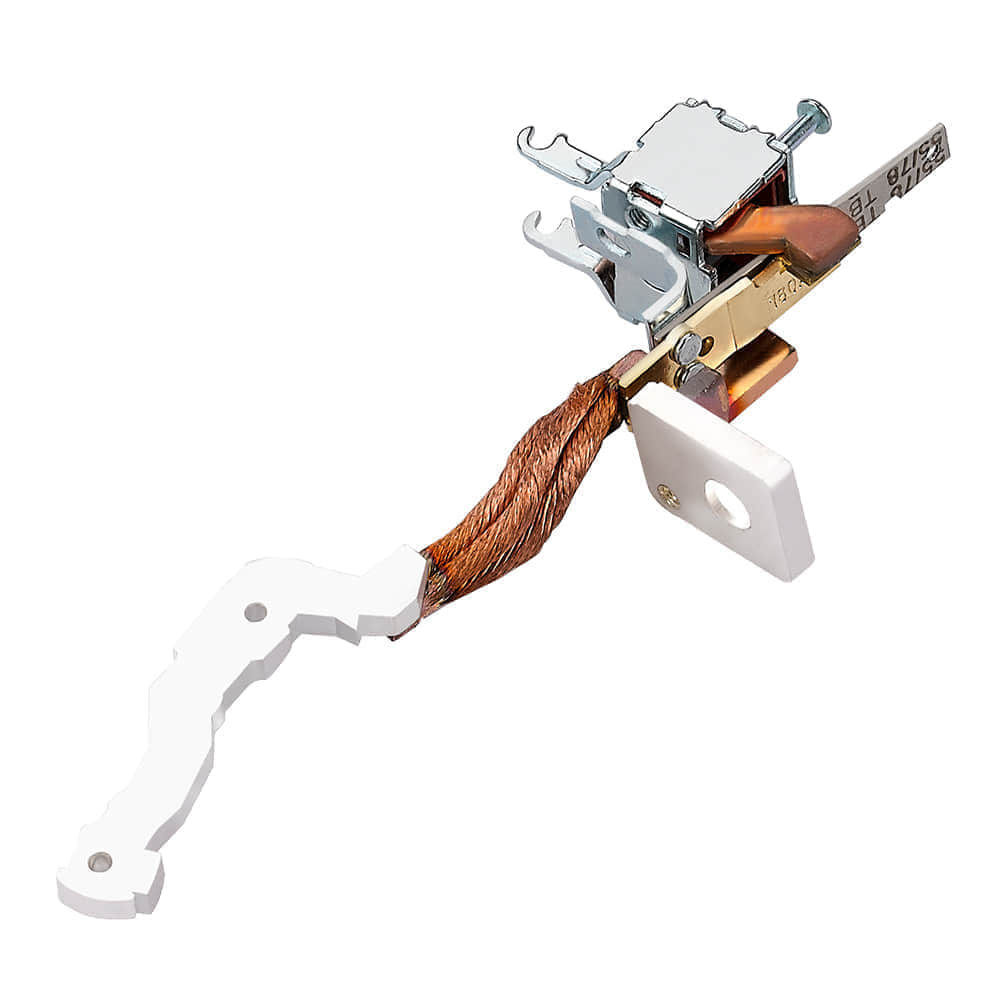

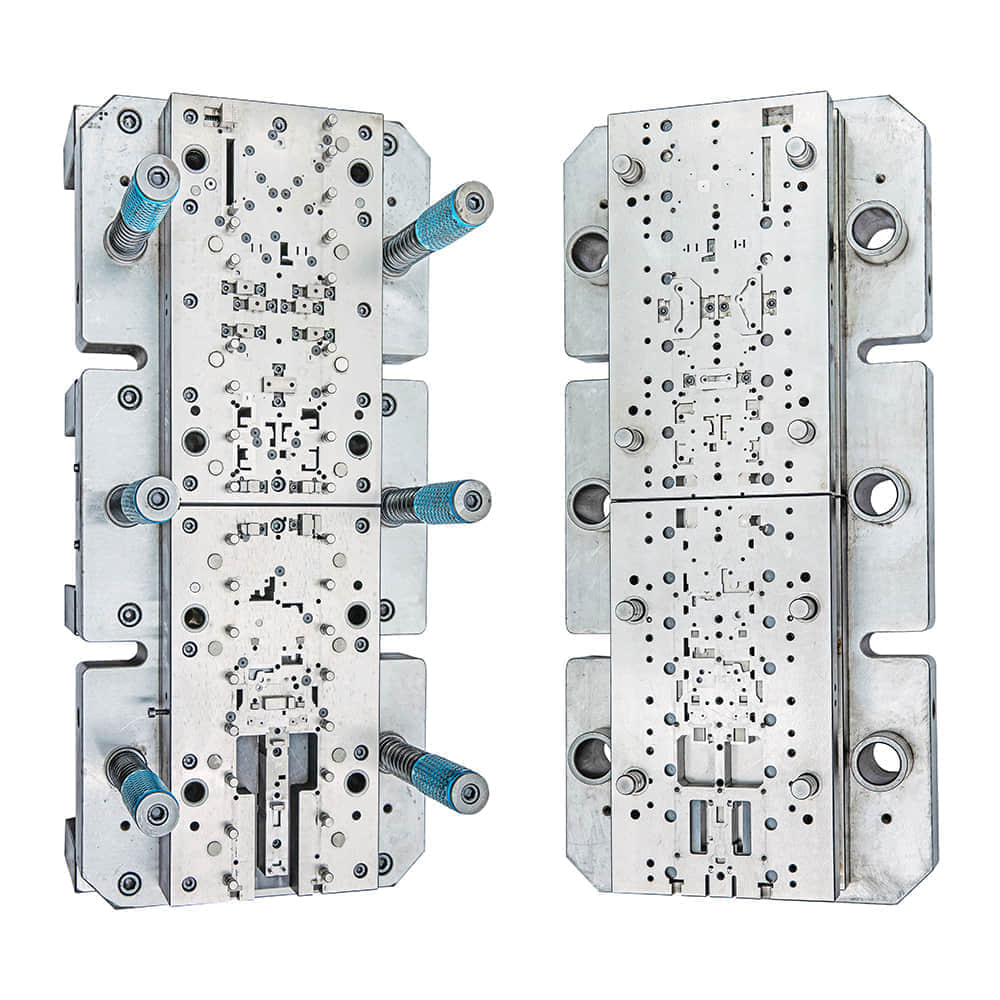

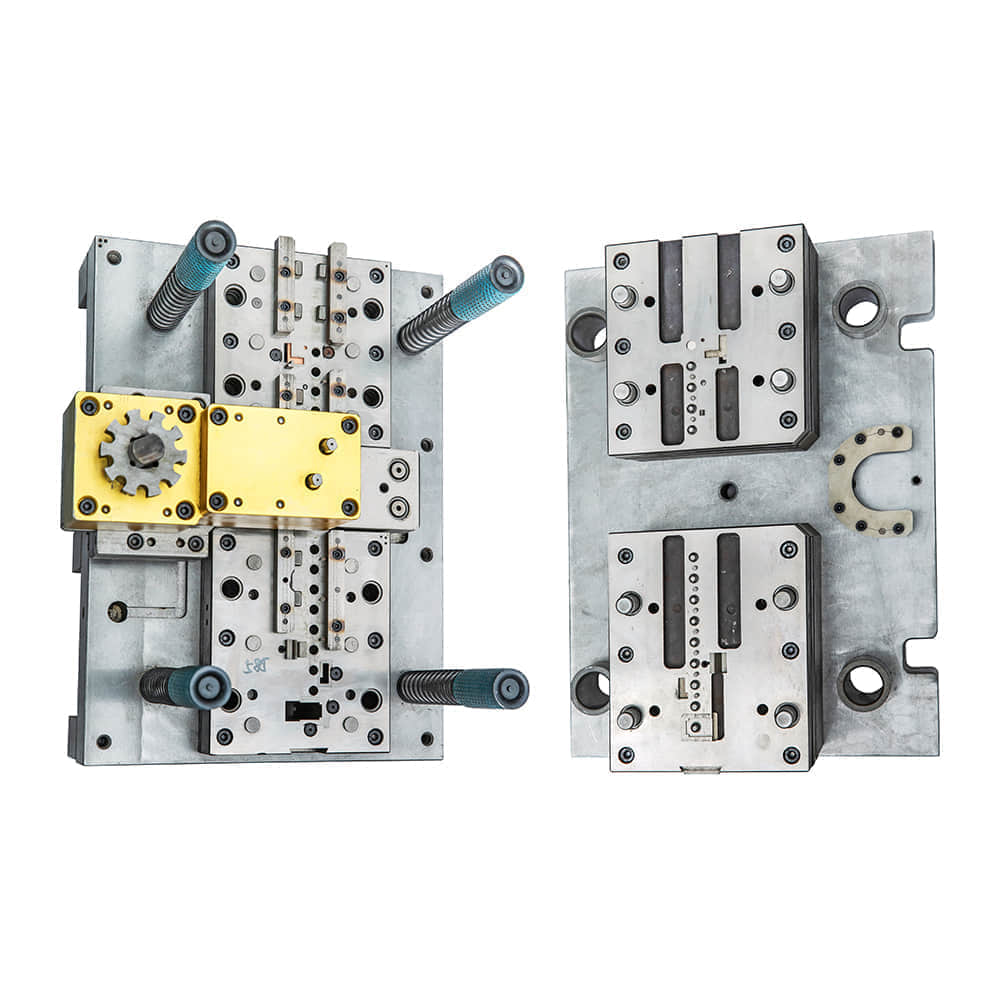

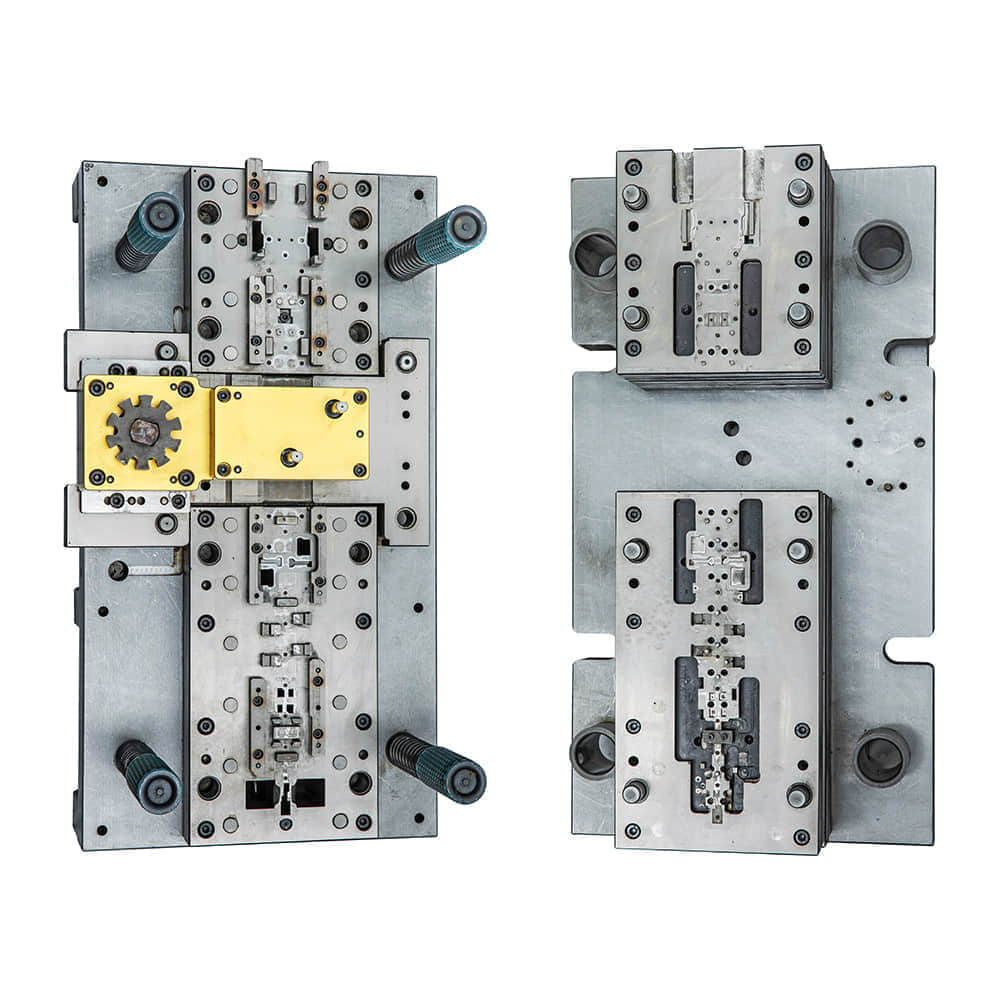

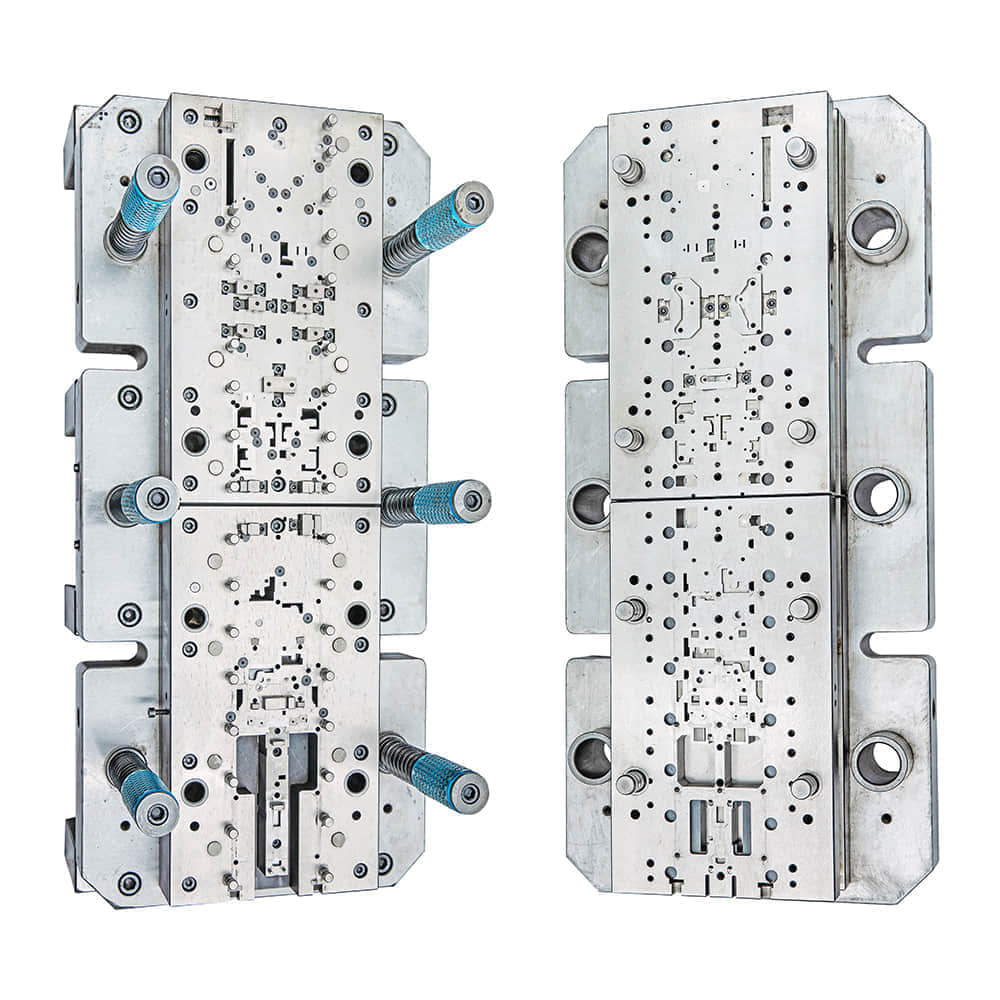

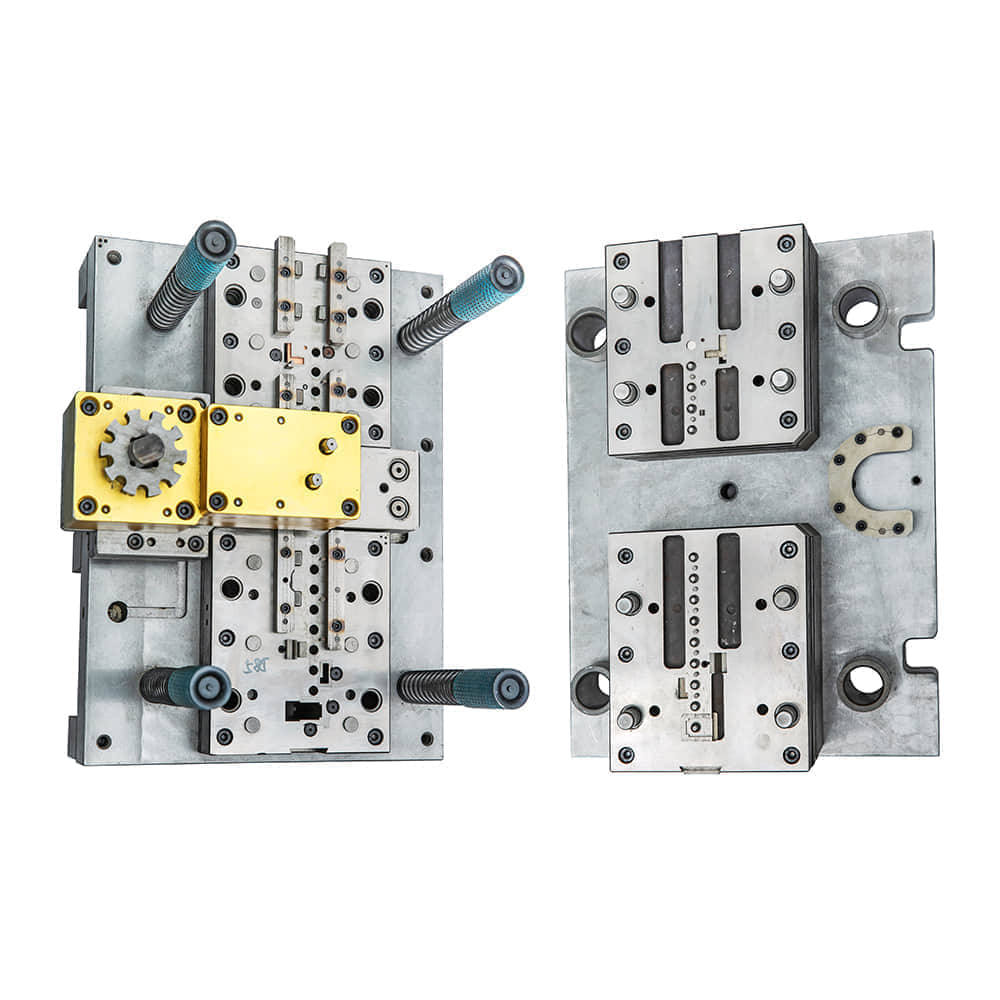

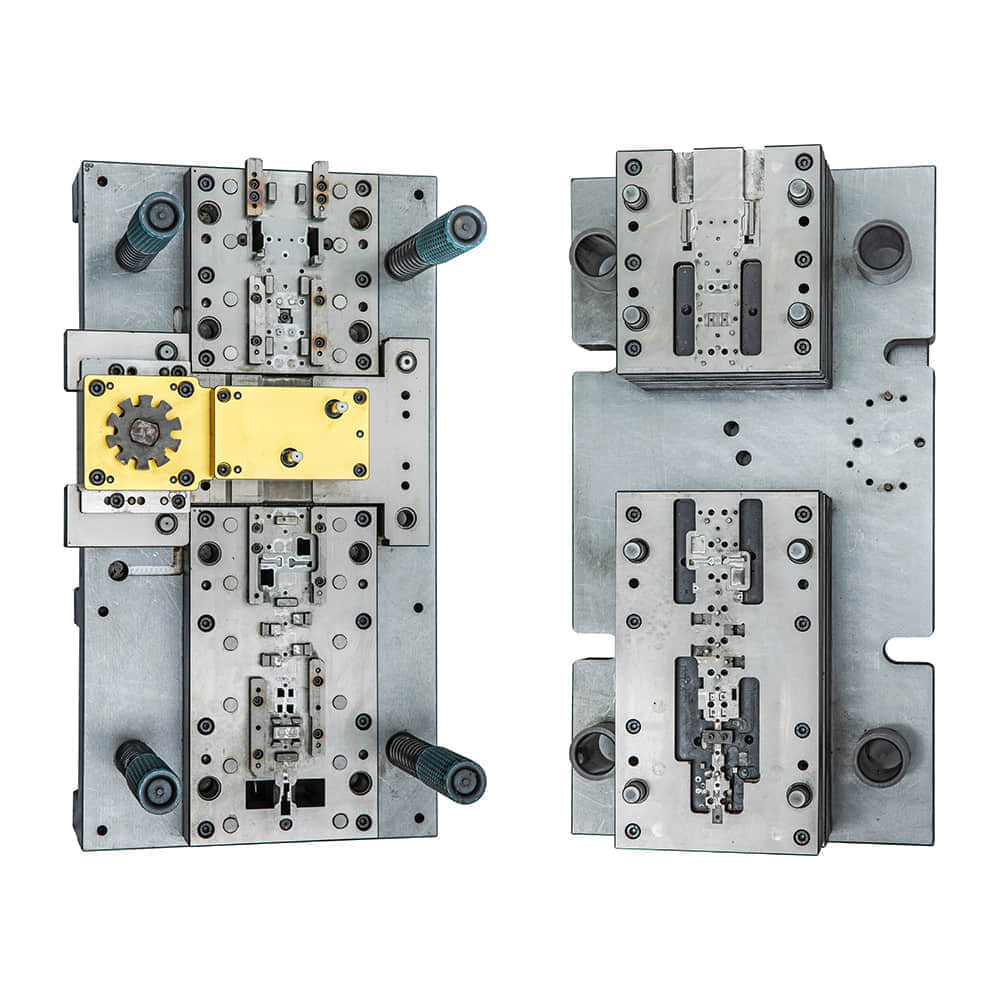

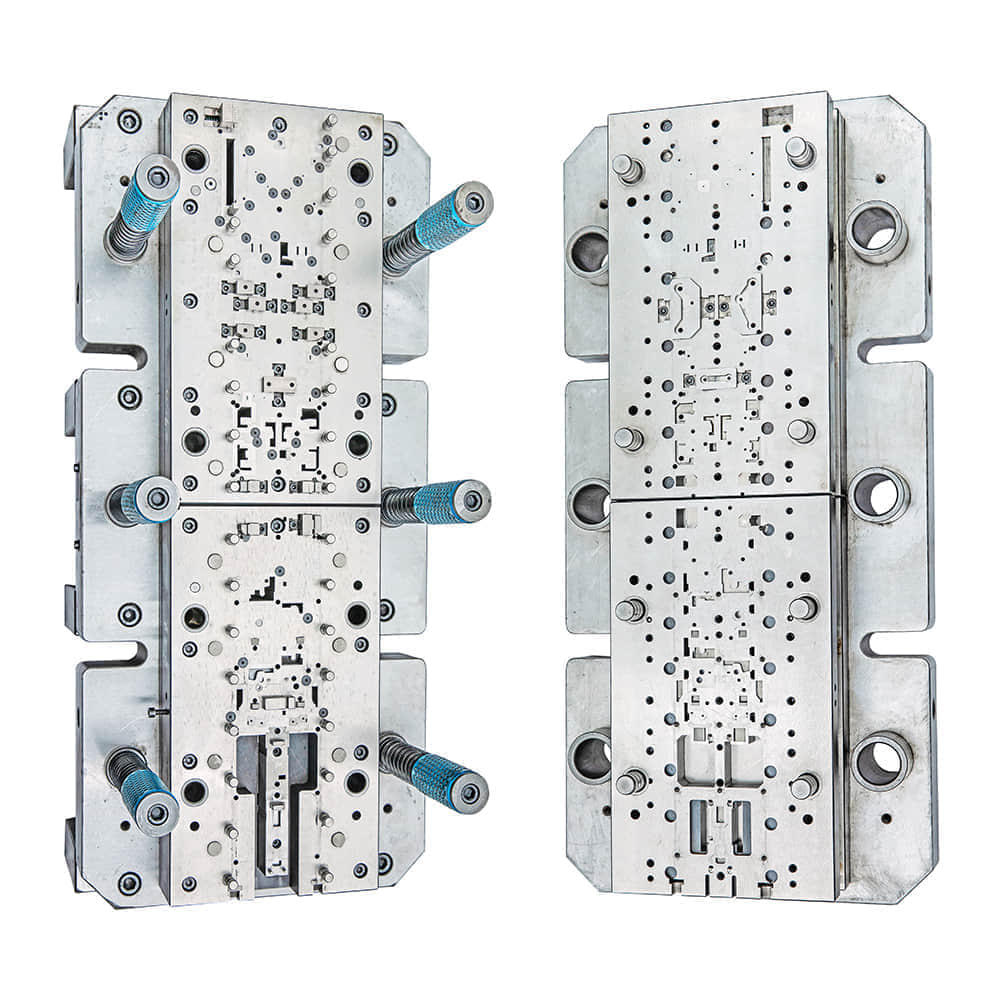

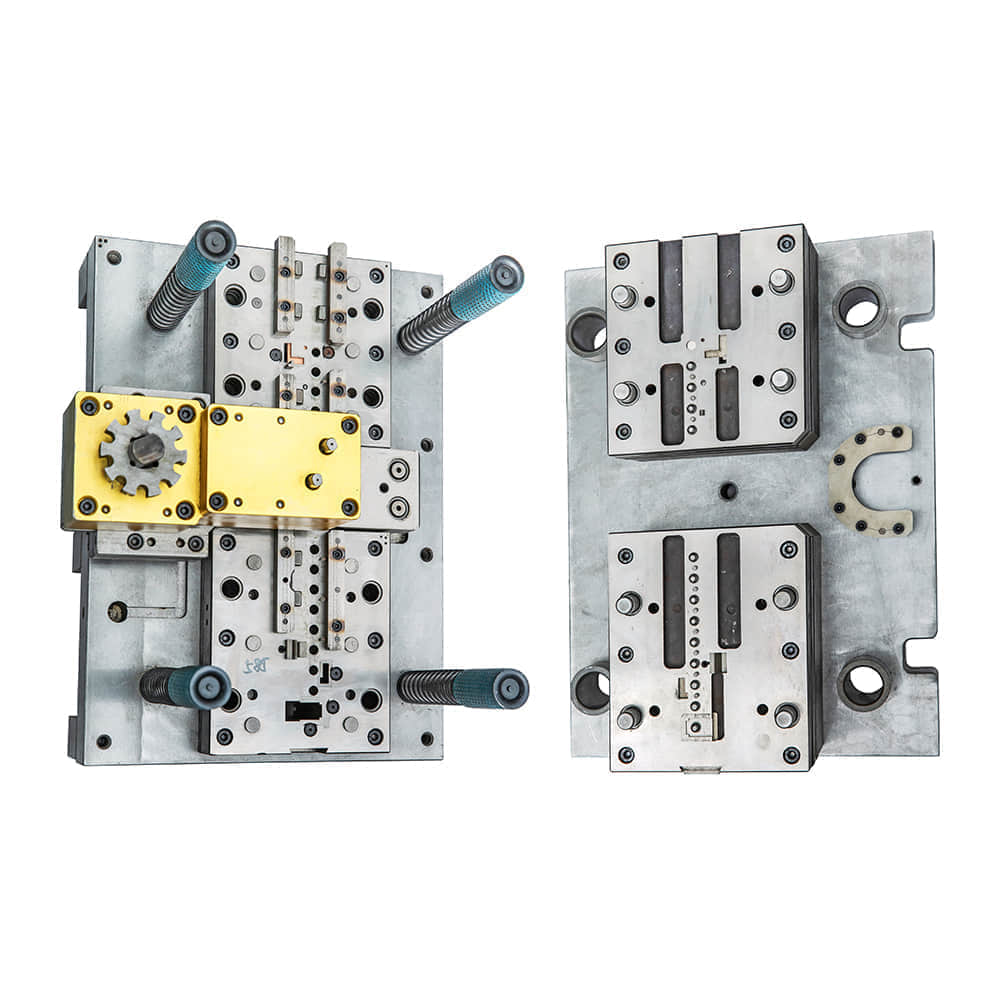

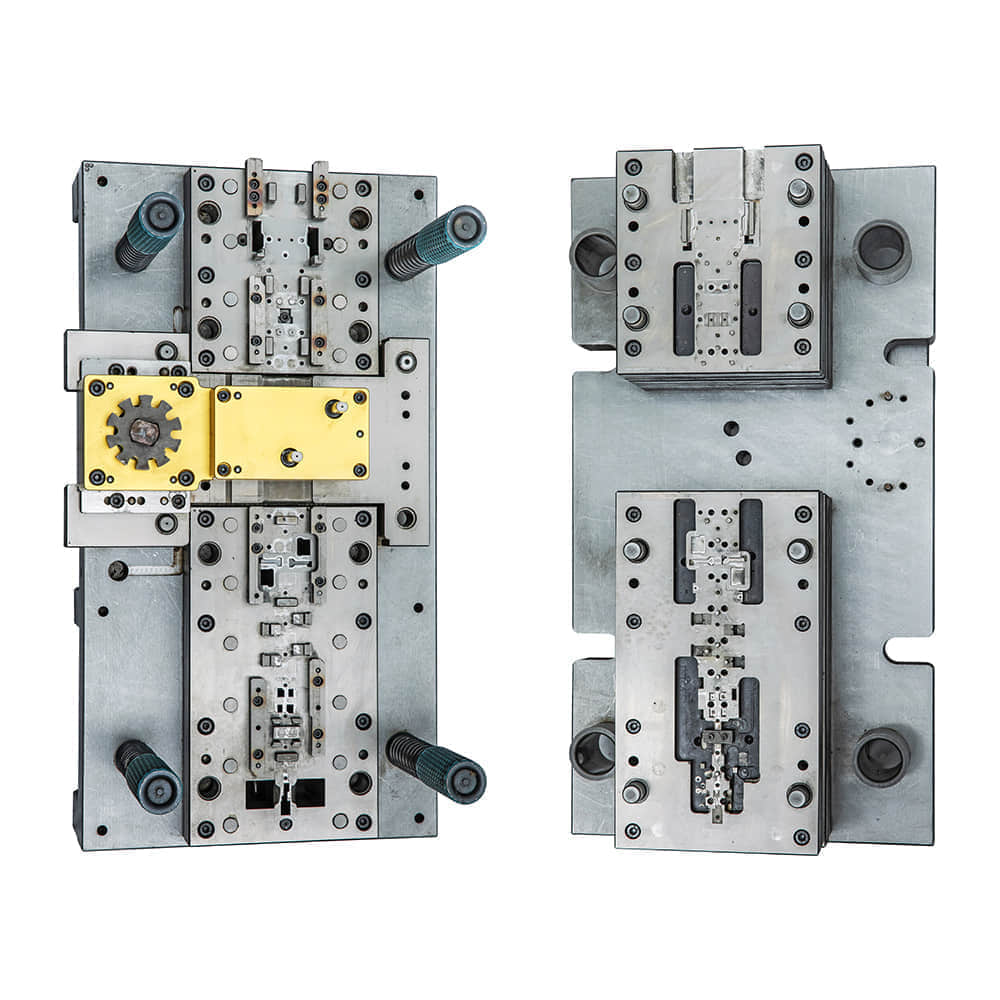

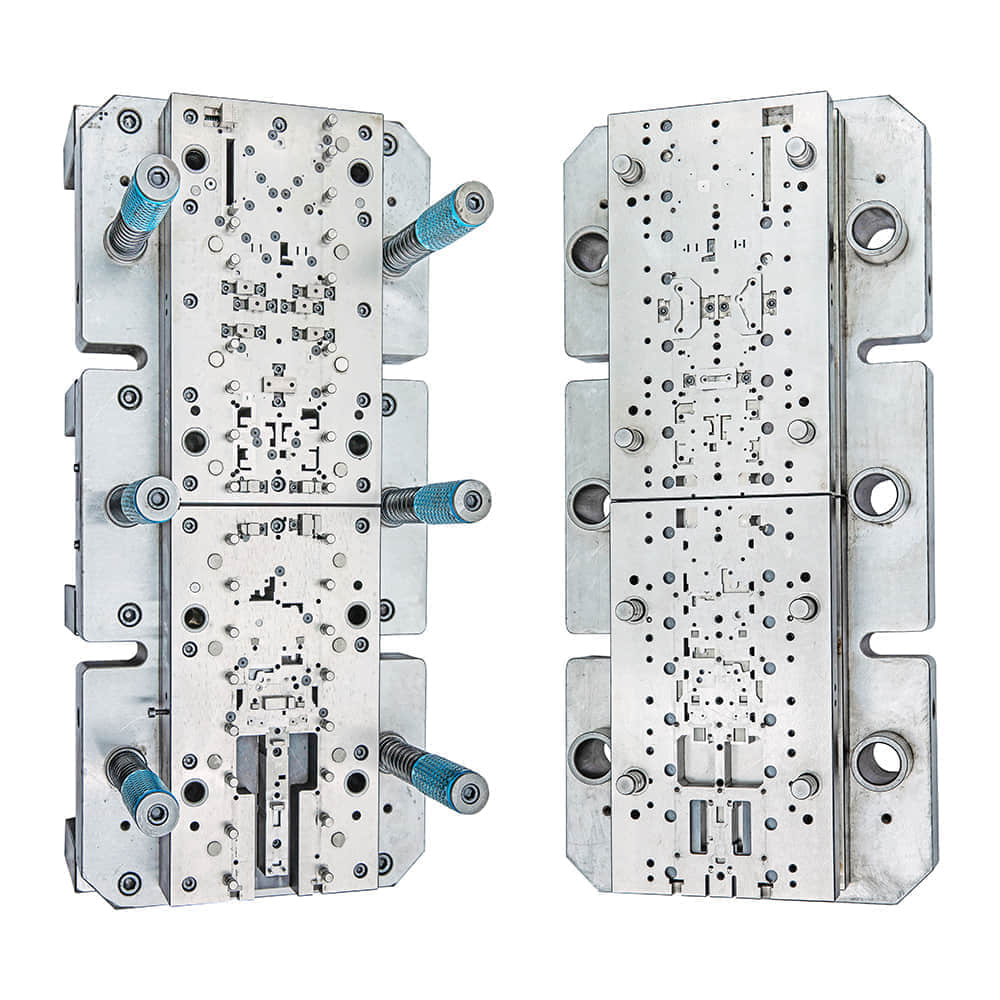

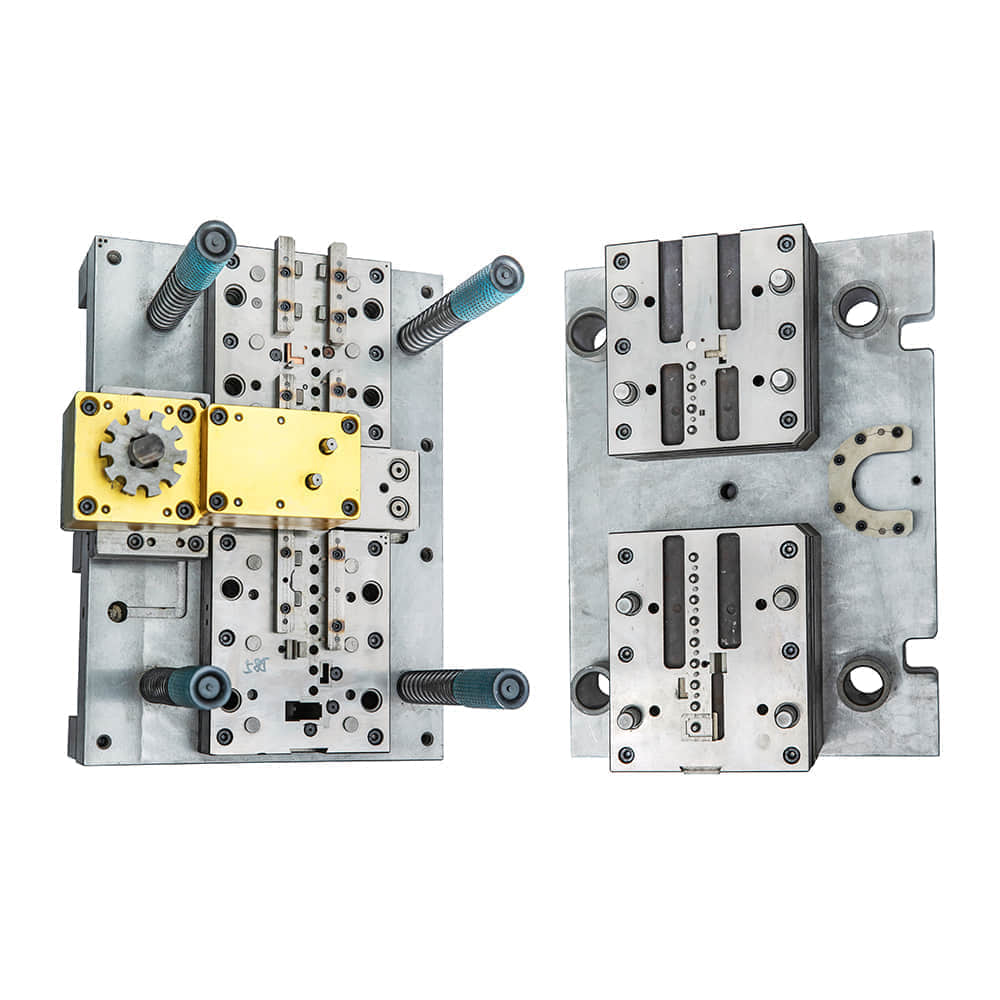

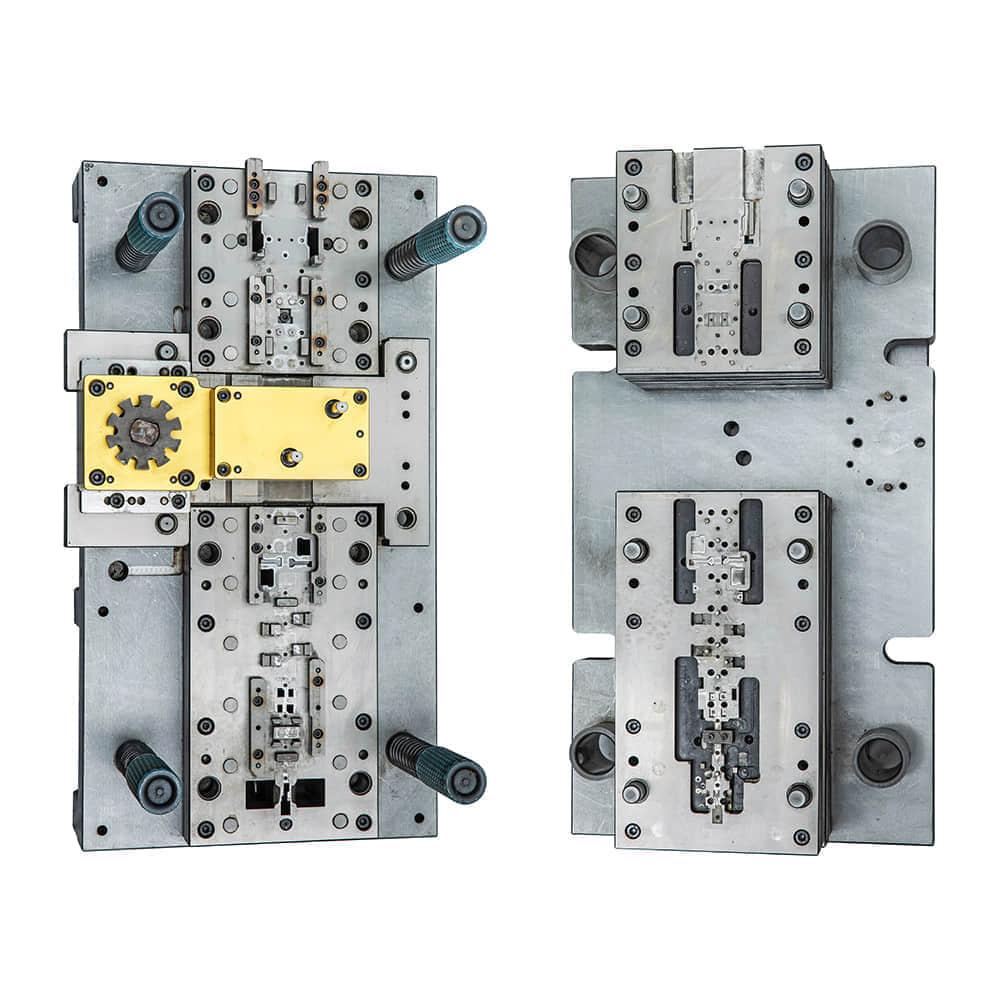

Metal stamping is a cost-effective method for producing high-quality metal parts in large quantities. Manufacturers rely on metal stamping to create components for industries such as automotive, aerospace, electronics, and appliances. The importance of metal stamping parts manufacturers lies in their ability to produce intricate and precise parts with exceptional consistency and efficiency. The Metal Stamping Process Metal stamping is a process that involves cutting, bending, and shaping metal sheets or coils into various forms and sizes. This process is carried out in a series of steps, which include: Material Selection: Manufacturers choose the appropriate metal material based on the specific requirements of the part. Common materials include steel, aluminum, copper, and brass. Blanking: The metal sheet is cut into the desired shape, known as a blank, using a specialized cutting tool. This blank will become the base for the final part. Punching: The blank is placed in a stamping press, where a punch and die set work together to create holes, slots, or other features in the metal. Bending: Some parts may require bending to achieve the desired shape. Manufacturers use various tools and machinery to bend the metal accurately. Assembly: In some cases, multiple stamped parts need to be assembled to create a more complex component. Finishing: Surface treatments like painting, plating, or coating can be applied to enhance the appearance and durability of the parts. Applications of Metal Stamping Parts Metal stamping parts find applications in a wide range of industries, including: Automotive: Metal stamping is used to manufacture components such as chassis parts, brackets, and engine components. Aerospace: Critical aerospace parts like aircraft frames and structural components are often produced through metal stamping. Electronics: Stamped metal parts are used in various electronic devices, including connectors, heat sinks, and enclosures. Appliances: Household appliances, such as washing machines and refrigerators, rely on metal stamping for the production of panels and structural components. Medical Devices: Precision and reliability are essential in medical equipment, making metal stamping a preferred choice for many components. The Advantages of Choosing the Right Manufacturer Selecting the right metal stamping parts manufacturer is crucial to ensuring the quality and performance of your products. Key advantages of partnering with a reputable manufacturer include: Expertise: Experienced manufacturers have the knowledge and skills to produce complex parts with precision. Cost Efficiency: Metal stamping offers cost-effective production for large quantities, reducing overall manufacturing costs. Consistency: Manufacturers can maintain consistent quality and tolerances, resulting in reliable and uniform parts. Customization: Many manufacturers offer customization options to meet unique project requirements. Quick Turnaround: Efficient production processes allow for faster turnaround times, meeting tight production schedules. In conclusion, metal stamping parts manufacturers are the backbone of various industries, providing essential components for countless products. Their expertise, precision, and efficiency make them indispensable partners for businesses looking to produce high-quality metal parts. Whether in automotive, aerospace, electronics, appliances, or medical devices, metal stamping plays a vital role in shaping our modern world.