In the ever-evolving landscape of manufacturing, DMC molding stands as a beacon of innovation and precision. As a leading DMC (Dough Molding Compound) molding manufacturer, this industry titan has established itself as a formidable force in the production of high-quality composite materials. With a commitment to excellence and a passion for cutting-edge technology, DMC molding manufacturer has set new standards in this dynamic sector.

The Art of DMC Molding

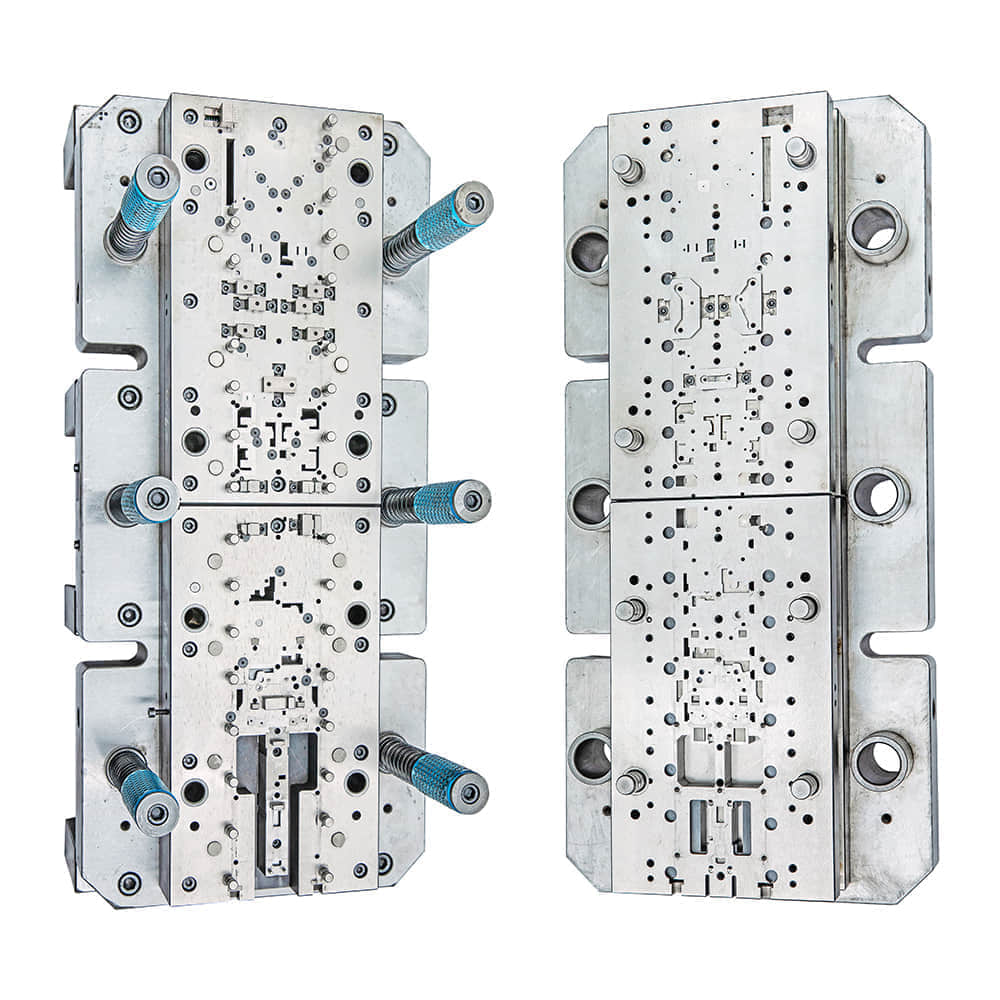

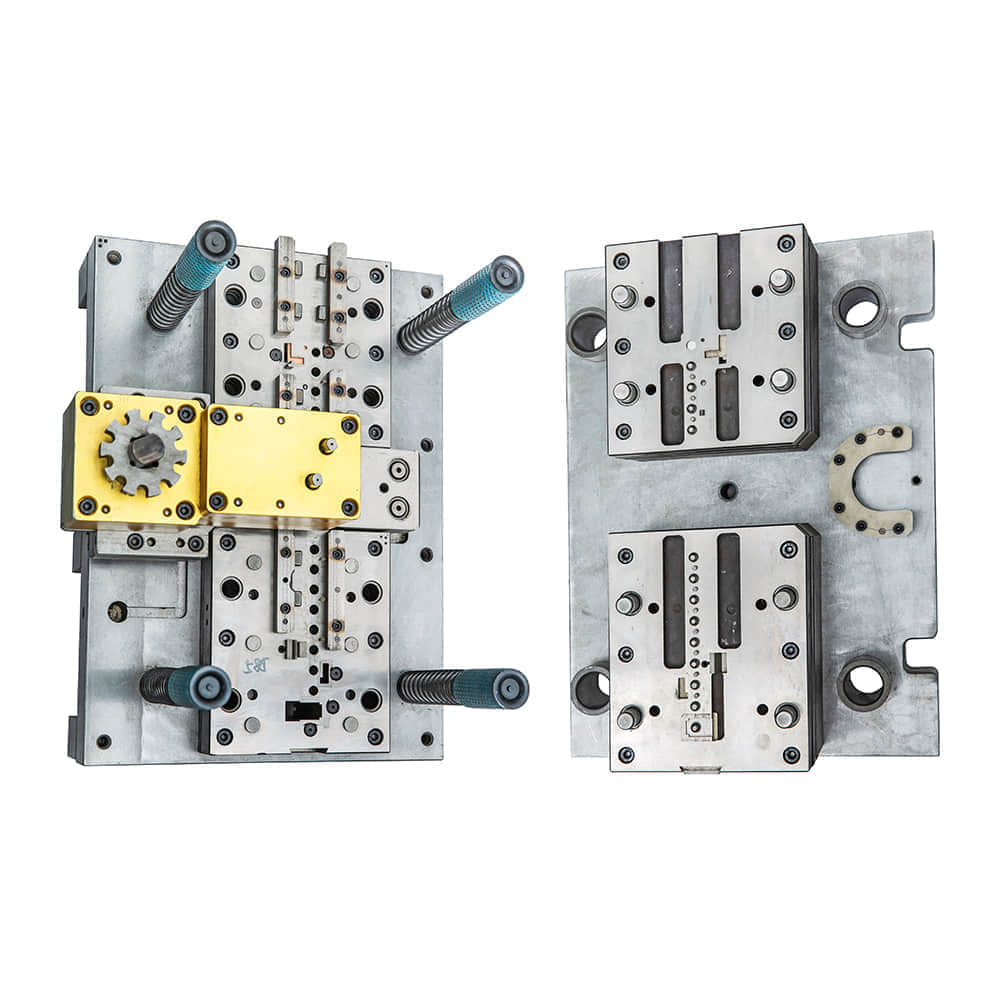

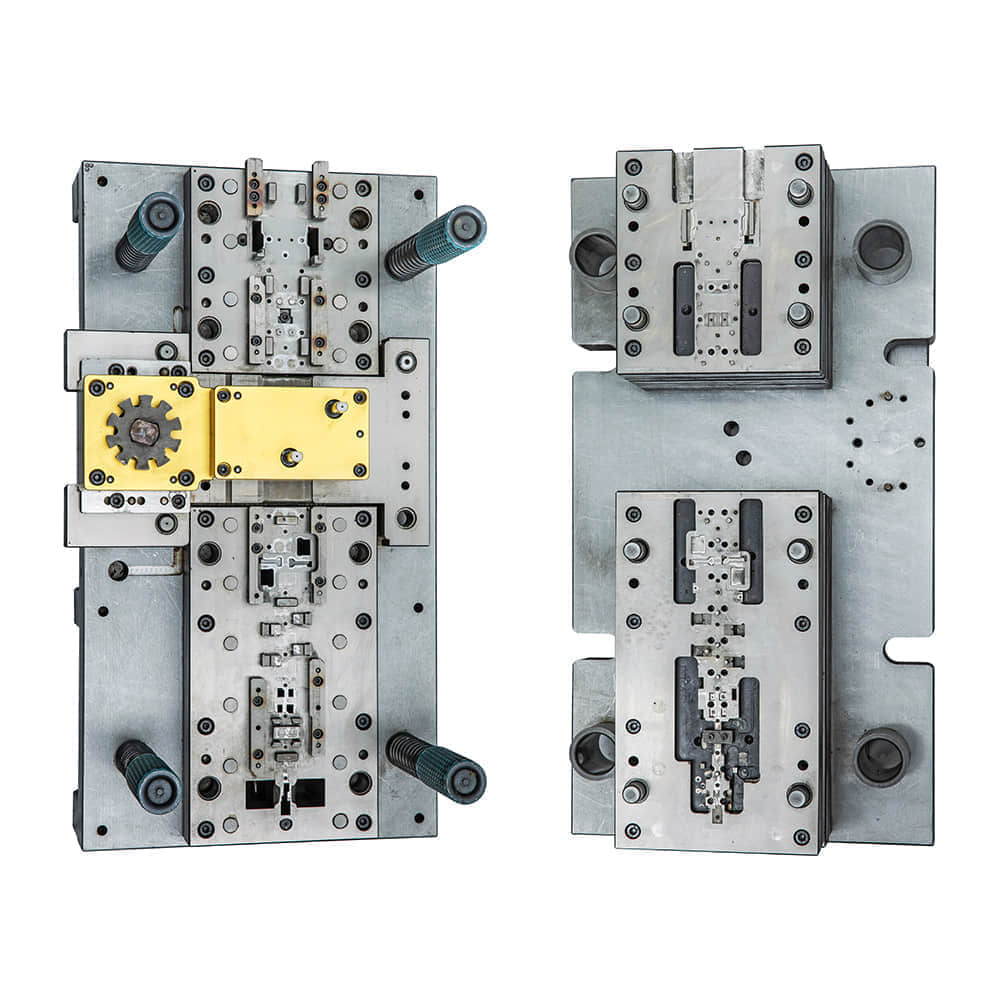

DMC molding, short for Dough Molding Compound molding, is a specialized process that involves shaping composite materials under high pressure and heat. This technique combines thermosetting resins with various reinforcements such as fiberglass, carbon fiber, or aramid fibers. The result is a material renowned for its exceptional strength, durability, and versatility. Innovation at Its Core At the heart of DMC molding manufacturer’s success lies a relentless pursuit of innovation. They invest heavily in research and development to push the boundaries of what’s possible with composite materials. This dedication has led to the creation of novel formulations and molding techniques, allowing them to cater to diverse industries. A Wide Spectrum of Applications The versatility of DMC molding makes it an ideal choice for a wide spectrum of applications. From automotive components to electrical enclosures, aerospace parts to consumer appliances, DMC molding manufacturer has carved a niche for itself by producing components that meet the highest standards of quality and precision. Quality Assurance Quality assurance is a top priority for DMC molding manufacturer. They implement stringent quality control processes at every stage of production to ensure that every component meets or exceeds customer expectations. From material selection to mold design, from manufacturing to post-processing, quality is ingrained in every step of their operations. Sustainability and Environmental Responsibility In an era where environmental consciousness is paramount, DMC molding manufacturer leads by example. They are committed to sustainable manufacturing practices, with an emphasis on reducing waste, energy consumption, and emissions. Their dedication to eco-friendly operations not only benefits the planet but also enhances the long-term viability of their products. Global Reach, Local Expertise DMC molding manufacturer’s reach extends across the globe. With a network of facilities strategically located in key regions, they offer customers a seamless and reliable supply chain. Their local expertise ensures that clients receive personalized solutions that cater to their unique needs, no matter where they are based. Collaboration and Customization Collaboration is at the core of DMC molding manufacturer’s philosophy. They work closely with clients to understand their specific requirements and challenges. This collaborative approach enables them to offer customized solutions that are tailored to each customer’s needs, ensuring optimal results and satisfaction. Embracing the Future As technology continues to advance, DMC molding manufacturer remains at the forefront of the industry. They are actively exploring new materials, molding techniques, and automation technologies to stay ahead of the curve. With an eye on the future, they are poised to continue leading the way in DMC molding and composite materials manufacturing. Conclusion In the realm of DMC molding, DMC molding manufacturer shines as a symbol of innovation, quality, and sustainability. With a commitment to excellence, a global presence, and a dedication to shaping the future of manufacturing, they are not just a manufacturer but a partner in progress. As industries evolve and demand ever-higher standards, DMC molding manufacturer stands ready to meet the challenges and opportunities of tomorrow, one molding at a time.