In the intricate world of electrical systems, Moulded Case Circuit Breakers (MCCBs) stand as sentinels, safeguarding circuits from the perils of overload and short circuits. At the forefront of supplying these crucial devices is the Moulded Case Circuit Breaker Supplier, a critical link in ensuring electrical safety.

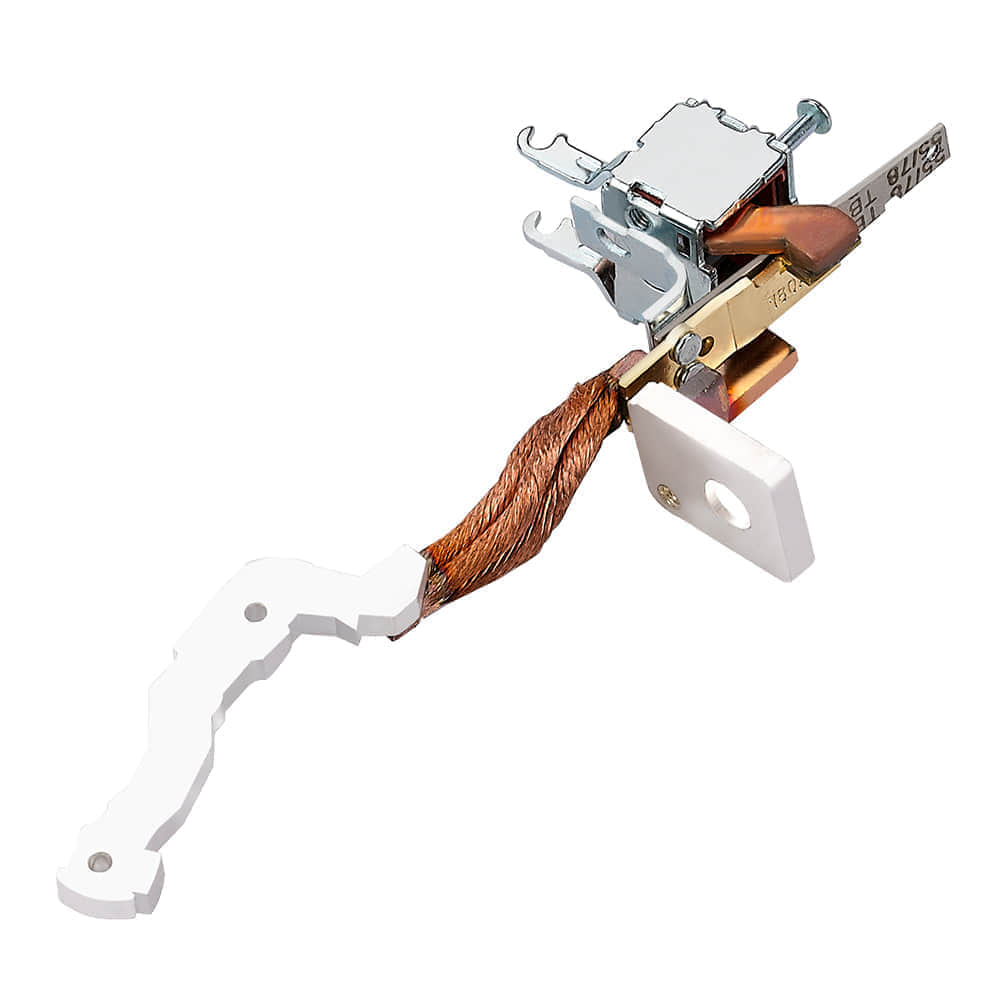

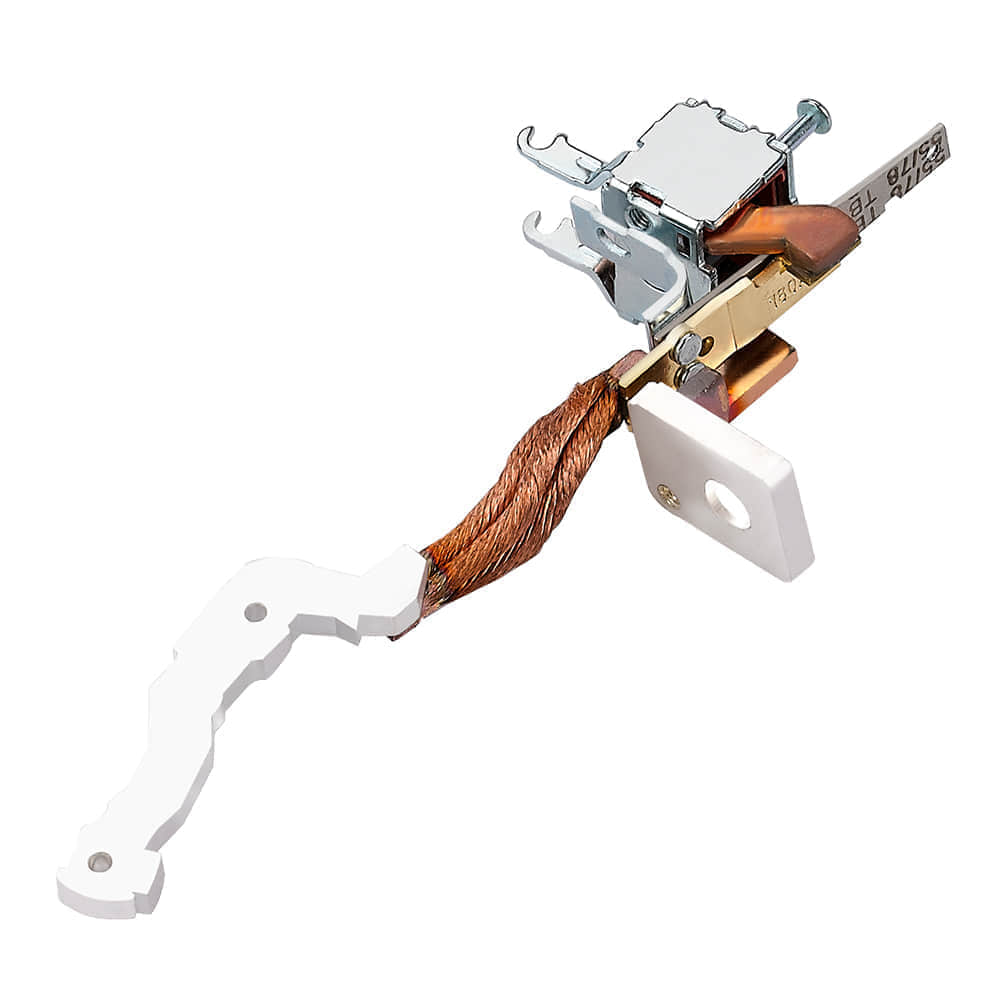

The Moulded Case Circuit Breaker Supplier specializes in manufacturing and distributing MCCBs that are designed to meet diverse circuit protection needs. These breakers, encased in robust moulded shells, offer a combination of durability and performance, making them a preferred choice for both commercial and industrial applications.

The core competency of a Moulded Case Circuit Breaker Supplier lies in its ability to offer a wide range of MCCBs, catering to various circuit ratings and load conditions. From low-voltage breakers suitable for residential use to high-voltage models designed for industrial applications, suppliers ensure that their inventory meets the diverse needs of their customers. Beyond the mere availability of products, Moulded Case Circuit Breaker Suppliers also prioritize the quality of their offerings. They adhere to strict manufacturing standards, employing high-grade materials and precision engineering techniques to ensure the reliability and longevity of their breakers. This commitment to quality is reflected in the products’ performance, which often exceeds industry standards.