In recent years, China has become a global leader in manufacturing advanced industrial components, and one of the key sectors contributing to this dominance is valve production. Among the many types of valves, the electric bellows stop valve has gained significant attention for its reliability and precision in regulating fluid and gas flow. Chinese manufacturers, known for their engineering expertise and cost-effective solutions, have established a strong presence in this specialized market, providing high-quality products to industries around the world.

What is an Electric Bellows Stop Valve?

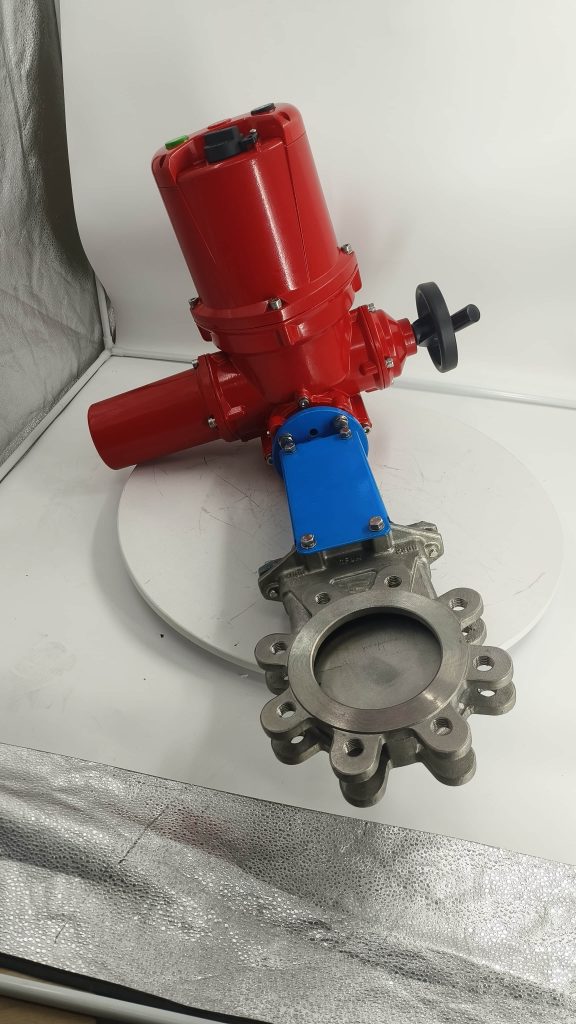

An electric bellows stop valve is a type of shutoff valve that uses electric power to control the operation of the valve, making it an essential component in automated systems. The primary function of this valve is to stop or regulate the flow of fluids, gases, or steam within pipelines. It consists of a bellows seal that provides a reliable and leak-proof closure, ensuring long-lasting performance even under high pressure or extreme temperature conditions. The electric actuator in the valve is responsible for opening and closing the valve based on signals from a control system. This type of valve is widely used in industries such as petrochemical, water treatment, HVAC systems, and power generation due to its ability to handle harsh operating conditions.