800V交流塑壳断路器是电力系统中至关重要的组件之一,它们在保护电路免受过载和短路等故障的影响方面发挥着不可替代的作用。本文将深入探讨800V交流塑壳断路器的工作原理、应用领域以及其在电力安全中的关键作用。

工作原理

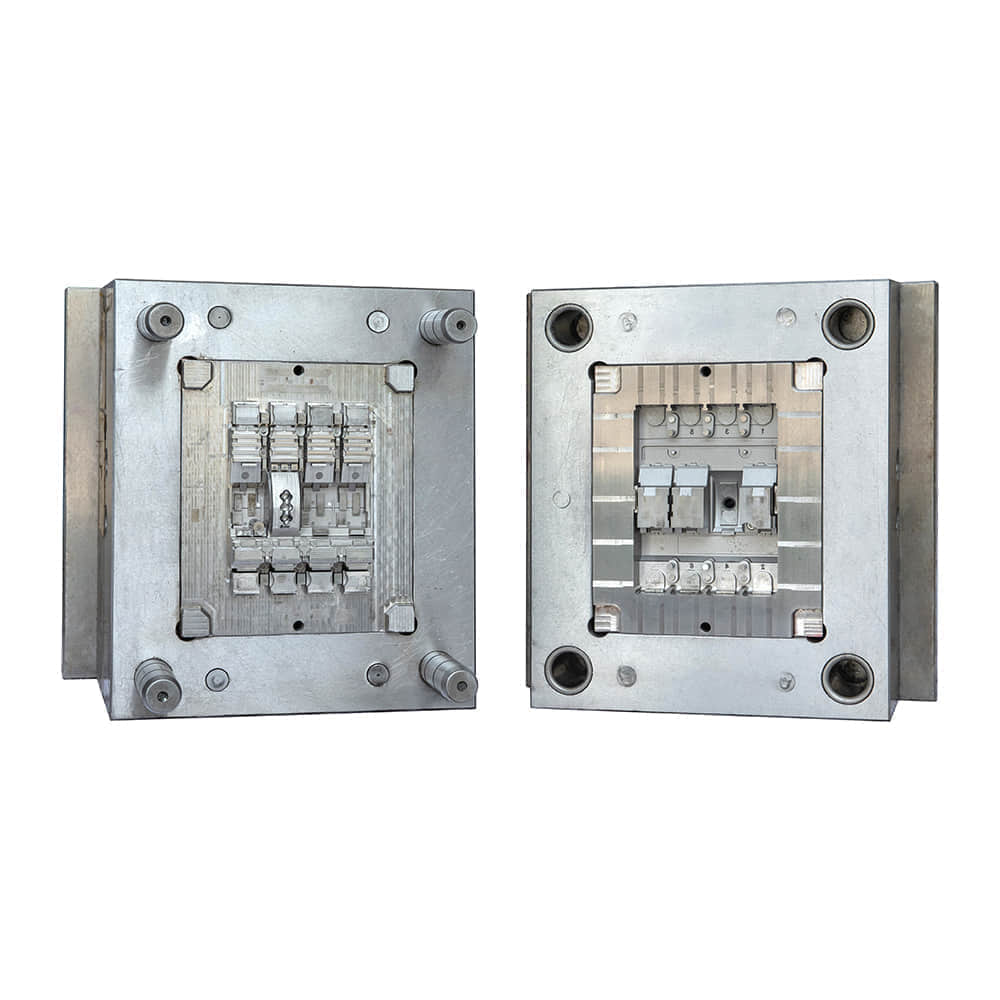

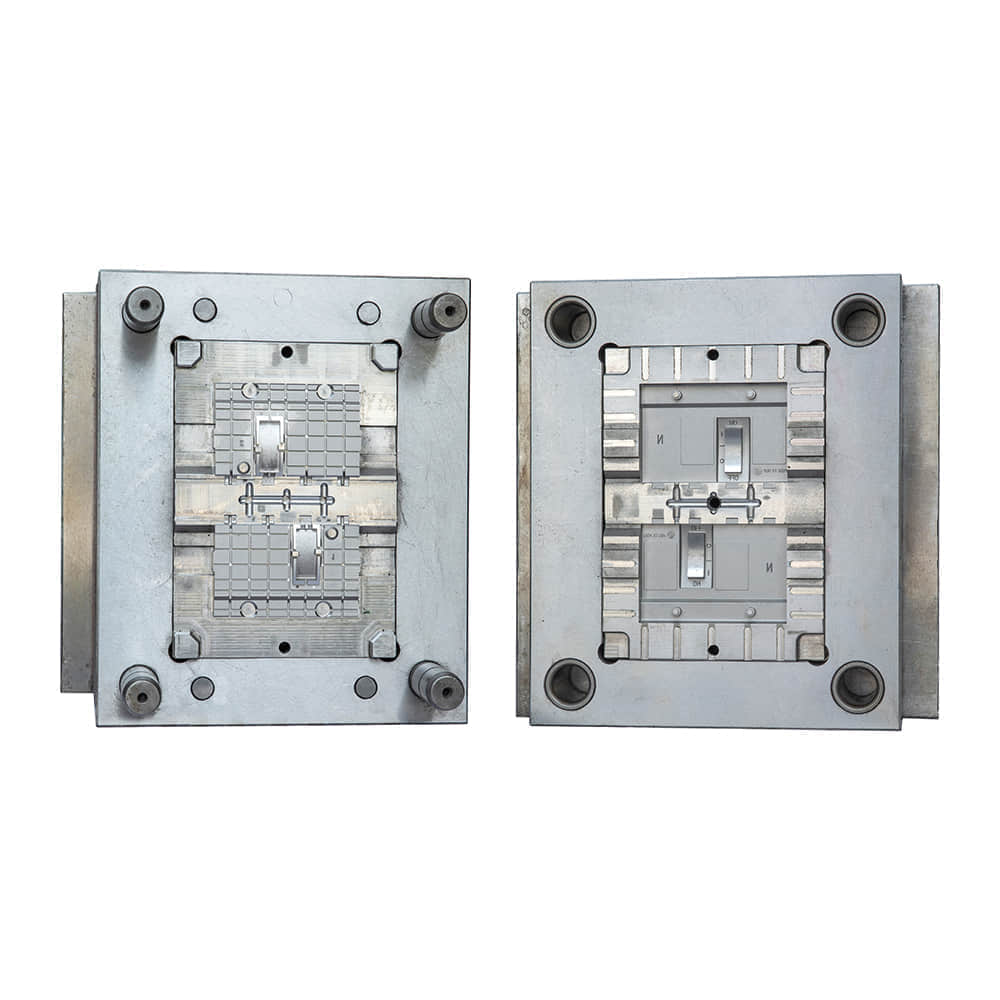

800V交流塑壳断路器是一种电器设备,用于在电路中断电流的流动,以防止电气设备或电线受到损害。它们的工作原理基于电磁感应和热保护机制。当电流超过额定值时,断路器内部的电磁触发器将激活,打开断路器,切断电路。此外,断路器还配备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,断路器也会自动断开电路,以防止火灾或设备损坏。 应用领域 800V交流塑壳断路器广泛应用于各种领域,包括工业、商业和住宅。以下是一些常见的应用领域: 工业领域:在工厂和制造业中,这些断路器用于保护重要的生产设备和机械免受电力故障的影响。它们可以防止生产中断,提高生产效率。 商业建筑:商业建筑中的电气设备需要可靠的电力保护,以确保正常运营。800V交流塑壳断路器用于商场、办公楼和酒店等场所。 住宅:在住宅中,这些断路器通常用于分配电力并保护家庭电器免受电路过载或故障的影响。它们对于防止火灾和电击事故至关重要。 可再生能源:随着可再生能源的发展,如太阳能和风能,800V交流塑壳断路器也在这些系统中扮演着关键的角色,确保电能传输的安全和可靠性。 电力安全的卫士 800V交流塑壳断路器可以被看作是电力安全的卫士。它们的存在保障了电路的可靠运行,防止了电流过载和短路引起的危险。同时,这些断路器还有助于减少电力损耗,提高了能源效率。 此外,800V交流塑壳断路器的自动断开功能在电力故障发生时可以迅速切断电源,减少了火灾和设备损坏的风险。这对于保护人员生命和财产安全至关重要。 总之,800V交流塑壳断路器在现代电力系统中扮演着不可或缺的角色。它们通过监测电流和温度,及时切断电路,保护了电气设备、建筑物和人员的安全。因此,对于电力系统的可靠性和稳定性来说,800V交流塑壳断路器是不可或缺的一部分,确保了我们的电力供应始终安全可靠。 标题:ACB抽屉式框架断路器:电力系统的守护者 ACB抽屉式框架断路器,作为电力系统中的核心组件之一,在现代工业和商业应用中扮演着不可或缺的角色。本文将深入介绍ACB抽屉式框架断路器的工作原理、特点、应用领域以及其在电力系统中的重要性。 工作原理 ACB(Air Circuit Breaker)抽屉式框架断路器是一种电器设备,用于在电路中断开电流的流动,以保护电气设备、线路和人员的安全。其工作原理基于电磁触发器和热保护机制的组合。当电流超过额定值或发生短路时,断路器内的电磁触发器会激活,引致断路器自动跳闸,切断电路。此外,ACB还装备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,断路器将自动断开电路,防止过载和火灾的发生。 特点 ACB抽屉式框架断路器具有以下显著特点: 可靠性:ACB的设计和制造严格遵循国际标准,确保其高度可靠性。这意味着它们能够在长时间内稳定工作,减少了电路中断的风险。 可维护性:ACB的抽屉式设计使得维护和更换变得非常方便。当需要维修或更换时,可以轻松地将抽屉拉出,而不必中断整个电路系统。 灵活性:ACB可以适应不同的电压等级和电流需求,因此适用于各种应用场合,从住宅到工业厂房。 高性能:ACB通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,保护设备和人员的安全。 应用领域 ACB抽屉式框架断路器在多个领域中都有广泛的应用: 工业生产:在工厂和制造业中,ACB用于保护关键的生产设备免受电力故障的危害。它们有助于确保生产的连续性和稳定性。 商业建筑:商业建筑中的ACB确保了电力系统的可靠性,防止了电路中断对正常运营的影响,如购物中心、写字楼等。 能源分配:ACB用于能源分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,ACB在太阳能和风能系统中起到关键作用,保护这些系统免受电力波动和故障的影响。 电力系统的守护者 总之,ACB抽屉式框架断路器是电力系统的守护者,通过可靠的工作原理和灵活的特点,确保了电力系统的安全和可靠运行。它们在防止电路过载、短路和火灾等方面发挥了至关重要的作用,保护了电力设备、线路和人员的安全。因此,对于任何电力系统而言,选择和维护ACB都是至关重要的,以确保电力供应的稳定性和可靠性。 标题:3000A框架断路器:电力保护的卓越之选 3000A框架断路器作为电力系统中的重要组件,发挥着关键的保护作用。本文将深入探讨3000A框架断路器的工作原理、应用领域以及在电力保护中的杰出表现。 工作原理 3000A框架断路器是一种用于断开电路中电流流动的电器设备,以保护电力系统、设备和人员的安全。其工作原理基于电磁触发和热保护机制。当电流超出额定值或电路发生故障时,断路器内部的电磁触发器将激活,导致断路器自动跳闸,切断电路。此外,它还配备了热保护装置,可监测电路中的温度,一旦温度升高到危险水平,断路器将迅速切断电源,以防止过载和火灾。 特点 3000A框架断路器具备多项引人注目的特点: 高容量:3000A的额定电流容量使得这种断路器适用于大型工业和商业电力系统,能够稳定地处理高负载。 可靠性:经过严格测试和质量控制,这些断路器具有卓越的可靠性,能够长时间保持稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,从而满足多种应用场合的要求。 高性能:3000A框架断路器通常具有快速的中断能力,可以在电流超出安全范围时快速切断电路,确保设备和人员的安全。 应用领域 3000A框架断路器在各种领域中都有广泛的应用: 工业生产:在大型工业设施中,这些断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力需求往往很大,3000A框架断路器用于保护电路和设备,确保电力系统的可靠性。 数据中心:数据中心对电力供应的可靠性要求极高,这些断路器可确保数据中心的连续运行,避免数据丢失和业务中断。 发电站:在发电站中,3000A框架断路器用于保护发电设备,确保电力产生和输送的安全性和可靠性。 电力保护的卓越之选 总之,3000A框架断路器是电力保护的卓越之选,通过其高容量、可靠性和高性能,保护了电力系统、设备和人员的安全。它们在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和稳定性。因此,在选择电力保护设备时,3000A框架断路器无疑是一种可信赖的选择,能够在各种应用中表现出色。 标题:MCCB冲制五金零部件:电力保护的坚实后盾 在现代电力系统中,MCCB(Molded Case Circuit Breaker)冲制五金零部件扮演着关键的角色,是电力保护的坚实后盾。本文将深入探讨MCCB冲制五金零部件的重要性、工作原理、应用领域以及其在电力保护中的不可或缺之处。 重要性 MCCB冲制五金零部件是MCCB的核心组成部分,负责断开电路中的电流流动,以保护电力系统和设备免受过载和短路等故障的影响。它们的重要性不言而喻,因为它们直接影响到电力系统的可靠性和安全性。这些五金零部件必须经过精确制造和高质量控制,以确保它们在关键时刻能够可靠地工作。 工作原理 MCCB冲制五金零部件的工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路故障时,断路器内部的电磁触发器被激活,导致断路器自动跳闸,切断电路。此外,这些五金零部件还具备热保护功能,可以监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止火灾或设备损坏。 应用领域 MCCB冲制五金零部件广泛应用于各种领域: 工业生产:在工厂和制造业中,这些五金零部件用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力需求巨大,MCCB冲制五金零部件用于保护电路和设备,确保电力系统的可靠性。 能源分配:它们也用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,如太阳能和风能,MCCB冲制五金零部件在这些系统中扮演关键角色,确保电能传输的安全性和可靠性。 电力保护的不可或缺之处 MCCB冲制五金零部件是电力保护的不可或缺之处。它们通过监测电流和温度,及时切断电路,保护了电力设备、线路和人员的安全。这些零部件的高质量制造和精确工作确保了电力系统的稳定性,减少了火灾、电击事故和设备损坏的风险。 总之,MCCB冲制五金零部件是电力保护中的关键组成部分,它们在电力系统中起着不可或缺的作用。它们的工作原理、应用领域和可靠性使其成为电力保护的坚实后盾,确保了电力系统的稳定和安全运行。因此,在设计和维护电力系统时,选择和使用高质量的MCCB冲制五金零部件至关重要,以确保电力供应的可靠性和安全性。 标题:塑壳断路器:电力系统的守护神 塑壳断路器是电力系统中不可或缺的关键组件,它们扮演着保护电路、设备和人员安全的重要角色。本文将深入探讨塑壳断路器的工作原理、类型、应用领域以及在电力系统中的关键作用。 工作原理 塑壳断路器是一种电器设备,用于在电路中断开电流流动,以防止电气设备或电线受到损害。它们的工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会激活,导致断路器自动跳闸,切断电路。此外,塑壳断路器还配备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 类型 塑壳断路器根据其额定电流容量和用途不同,分为多种类型,包括: 低压断路器:用于低电压(通常低于1000V)电力系统,例如住宅和商业建筑。 中压断路器:用于中电压(通常在1000V到10000V之间)的电力系统,例如工业设备和发电厂。 高压断路器:用于高电压电力系统,通常在10000V以上,例如电网输电线路。 直流断路器:专用于直流电路,例如太阳能和风能发电站。 应用领域 塑壳断路器在各种应用领域中发挥着关键作用: 工业领域:在工厂和制造业中,塑壳断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力设备和电路需要可靠的保护,塑壳断路器确保了电力系统的可靠性。 能源分配:塑壳断路器用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,塑壳断路器在太阳能和风能系统中起到关键作用,保护这些系统免受电力波动和故障的影响。 电力系统的守护神 总之,塑壳断路器可以被看作是电力系统的守护神。它们通过可靠的工作原理和多种类型的适用性,保护了电力设备、线路和人员的安全。塑壳断路器的重要性在于,它们可以及时切断电路,防止电流过载、短路和火灾等电气故障的发生。因此,在设计和维护电力系统时,选择适当类型和高质量的塑壳断路器至关重要,以确保电力供应的可靠性和安全性。在电力系统中,塑壳断路器是一位不可或缺的守护神,为我们的电力世界提供了稳定、可靠和安全的电力保护。 标题:智能式框架断路器:电力安全的未来 随着科技的不断发展,智能电力系统已成为现实。在这一趋势中,智能式框架断路器崭露头角,成为电力系统的未来。本文将深入探讨智能式框架断路器的工作原理、特点、应用领域以及其在电力安全中的革命性作用。 工作原理 智能式框架断路器结合了传统断路器的电流保护功能和现代数字技术的智能化。它们能够监测电路中的电流、电压和温度等参数,并将这些数据传输到集中式控制系统或云端平台。当电流超过安全范围、电压异常或温度升高到危险水平时,智能断路器能够自动触发断路,切断电路,从而保护设备和人员的安全。 特点 智能式框架断路器具有多项令人瞩目的特点: 远程监控:用户可以通过互联网远程监控电力系统的状态,随时随地了解电路运行情况。 自主决策:智能断路器能够自主判断电路是否存在问题,并采取相应的措施,减少了人工干预的需求。 数据分析:通过收集和分析电力数据,智能断路器能够提供预测性维护,帮助用户避免设备故障和停机时间。 通信能力:它们可以与其他设备和系统进行通信,实现电力系统的集成化和智能化。 应用领域 智能式框架断路器已经在多个领域中得到了广泛应用: 工业自动化:在工业生产中,智能断路器可以监测设备运行状态,提高生产效率,并减少停机时间。 商业建筑:商业建筑中的电力系统需要高度可靠性,智能断路器可以实现实时监控和自动断电,提供更安全的电力分配。 可再生能源:在太阳能和风能系统中,智能断路器可以帮助管理电力波动,提高能源利用率。 电力网络:在电力传输和分配网络中,智能断路器有助于提高网络的可靠性和智能化管理。 电力安全的未来 随着电力系统的复杂性不断增加,智能式框架断路器已经成为电力安全的未来。它们不仅可以提供更高级别的电力保护,还可以通过数据分析和远程监控来优化电力系统的运行。这不仅有助于减少电力故障和设备损坏,还有助于提高电力系统的能效和可持续性。 因此,智能式框架断路器代表了电力保护技术的新方向,将为我们的电力系统带来更多创新和便利。作为电力安全的未来,智能式框架断路器将继续在各个领域中发挥关键作用,确保电力供应的可靠性和安全性,为我们的现代生活和工业生产提供坚实的支持。 标题:MCCB制造厂:电力保护的制高点 现代电力系统中,MCCB(Molded Case Circuit Breaker)制造厂扮演着至关重要的角色。本文将深入探讨MCCB制造厂的重要性、制造过程、质量控制以及对电力保护的贡献。 重要性 MCCB是电力系统的关键组件之一,负责在电路中断开电流流动,以保护电力系统、设备和人员的安全。MCCB制造厂的重要性在于,他们的产品决定了电力保护的质量和可靠性。优质的MCCB不仅能够快速、可靠地切断电路,还能够抵御恶劣环境和持续的高负载。 制造过程 MCCB的制造过程是高度精密和复杂的。它包括以下关键步骤: 设计:制造厂首先进行电路设计和外壳设计,确保MCCB能够在各种电流和电压条件下稳定工作。 材料选择:选择高质量的导电材料、断路器触点材料和外壳材料,以确保MCCB的导电性和耐用性。 生产:在生产线上,工人将各个部件组装起来,包括触发机构、热保护器和断路器触点等。 测试:每个MCCB都会经过严格的测试,包括电流负载测试、温度测试和机械耐久性测试,以确保其质量和性能。 质量控制:制造厂会实施严格的质量控制措施,确保每个MCCB都符合国际标准和安全要求。 质量控制 MCCB制造厂注重质量控制,以确保其产品的可靠性和安全性。他们采用严格的质量管理系统,包括ISO认证,以确保生产过程的透明度和一致性。制造厂还进行全面的检测和测试,确保每个MCCB都能够在实际应用中表现出色。 对电力保护的贡献 MCCB制造厂的产品对电力保护发挥着巨大作用。它们能够迅速切断电路,防止电流过载和短路引发的火灾和设备损坏。此外,MCCB还可以提供过载和短路保护设置,根据需要调整断开电路的电流范围,从而实现精确的电力保护。 MCCB制造厂的贡献不仅限于产品本身,还包括不断创新和改进,以适应不断发展的电力系统需求。他们研发出更智能化、数字化的MCCB,可以远程监控和管理电路,提供更高级别的电力保护。 结论 MCCB制造厂在电力保护领域扮演着不可或缺的角色。他们通过高质量的制造和严格的质量控制,确保MCCB的可靠性和性能,为电力系统提供了坚实的安全保障。作为电力保护的制高点,MCCB制造厂持续创新,为电力系统的可靠性、安全性和智能化提供了关键支持。 标题:3级塑壳开关:电力系统的可靠守护者 3级塑壳开关,作为电力系统中的关键组件之一,扮演着保护电路和设备安全运行的重要角色。本文将深入探讨3级塑壳开关的工作原理、特点、应用领域以及在电力系统中的不可或缺之处。 工作原理 3级塑壳开关是一种电气开关设备,通常用于低电压电力系统,其工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,开关内部的电磁触发器会被激活,导致开关自动跳闸,切断电路。此外,3级塑壳开关还装备了热保护装置,可监测电路中的温度,一旦温度升高到危险水平,也会触发开关,以防止过载和火灾。 特点 3级塑壳开关具备多项重要特点: 可靠性:经过严格的测试和质量控制,这些开关具有卓越的可靠性,能够长时间保持稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,从而满足多种应用场合的要求。 高性能:3级塑壳开关通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些3级塑壳开关具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 3级塑壳开关在多个领域中广泛应用: 工业生产:在工厂和制造业中,这些开关用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力需求巨大,3级塑壳开关用于保护电路和设备,确保电力系统的可靠性。 能源分配:它们用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,如太阳能和风能,3级塑壳开关在这些系统中发挥关键作用,保护电力传输的安全性和可靠性。 电力系统的可靠守护者 总之,3级塑壳开关被认为是电力系统的可靠守护者,通过其高可靠性、灵活性和高性能,保护了电力设备、线路和人员的安全。它们在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和稳定性。因此,在设计和维护电力系统时,选择和维护3级塑壳开关都至关重要,以确保电力供应的可靠性和安全性。这些开关是电力系统中的关键组件,为我们的电力世界提供了稳定、可靠和安全的守护。 标题:3级塑壳断路器:电力安全的坚实防线 3级塑壳断路器,作为电力系统中的关键组件,扮演着保护电路和设备安全运行的关键角色。本文将深入探讨3级塑壳断路器的工作原理、特点、应用领域以及在电力安全中的不可或缺之处。 工作原理 3级塑壳断路器是一种电气开关设备,用于在电路中断开电流流动,以保护电力系统、设备和人员的安全。其工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会被激活,导致断路器自动跳闸,切断电路。此外,3级塑壳断路器还装备了热保护装置,可监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 特点 3级塑壳断路器具备多项重要特点: 可靠性:这些断路器经过严格的测试和质量控制,具有卓越的可靠性,能够长期稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,满足多种应用场合的要求。 高性能:3级塑壳断路器通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些3级塑壳断路器具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 3级塑壳断路器在多个领域中广泛应用: 工业生产:在工厂和制造业中,这些断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力系统需要高度可靠性,3级塑壳断路器用于保护电路和设备,确保电力系统的可靠性。 能源分配:它们用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,如太阳能和风能,3级塑壳断路器在这些系统中发挥关键作用,保护电力传输的安全性和可靠性。 电力安全的坚实防线 总之,3级塑壳断路器被认为是电力系统的坚实防线,通过其高可靠性、灵活性和高性能,保护了电力设备、线路和人员的安全。它们在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和稳定性。因此,在设计和维护电力系统时,选择和维护3级塑壳断路器都至关重要,以确保电力供应的可靠性和安全性。这些断路器是电力系统中的重要组件,为我们的电力世界提供了坚实、可靠和安全的保护。 标题:商业用塑壳断路器:电力安全与商业持续性的保障 商业用塑壳断路器作为电力系统中的关键元件,对于商业场所的电力安全和持续性至关重要。本文将深入探讨商业用塑壳断路器的工作原理、特点、应用领域以及在商业环境中的不可或缺作用。 工作原理 商业用塑壳断路器是一种电气开关设备,其工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会被激活,导致断路器自动跳闸,切断电路。此外,商业用塑壳断路器还配备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 特点 商业用塑壳断路器具有多项重要特点: 可靠性:这些断路器经过严格的测试和质量控制,具有卓越的可靠性,能够长期稳定工作。 灵活性:商业用塑壳断路器具备可调的短路保护设置,可适应不同电流需求,满足多种商业场所的要求。 高性能:它们通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些商业用塑壳断路器具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 商业用塑壳断路器在多个领域中广泛应用: 商铺和办公场所:商业用塑壳断路器用于保护商铺和办公场所的电力系统,确保设备的正常运行。 餐厅和酒店:在餐饮和酒店业中,电力供应的可靠性对于顾客满意度至关重要,这些断路器用于保护厨房设备、照明和空调系统。 购物中心:购物中心需要大量电力供应,商业用塑壳断路器用于维护购物中心的电力稳定性。 金融机构:银行和金融机构依赖于高度可靠的电力供应,以确保交易和数据处理的顺畅进行。 电力安全与商业持续性的保障 总之,商业用塑壳断路器是商业场所电力系统的关键组成部分,它们通过高可靠性、灵活性和高性能,保护了商业场所的电力设备、线路和员工的安全。商业用塑壳断路器在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和商业持续性。因此,在商业环境中,选择和维护商业用塑壳断路器都至关重要,以确保电力安全和商业运营的持续性。这些断路器不仅是商业场所的电力安全保障,也是商业成功的一部分,为商业世界提供了坚实的电力安全保障。 标题:800V交流塑壳断路器:电力系统的卫士 800V交流塑壳断路器是电力系统中至关重要的组成部分,它们在保护电路、设备和人员安全方面扮演着关键的角色。本文将深入探讨800V交流塑壳断路器的工作原理、特点、应用领域以及在电力系统中的重要作用。 工作原理 800V交流塑壳断路器是一种电器设备,用于在电路中断开电流流动,以防止电气设备或电线受到损害。它们的工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会激活,导致断路器自动跳闸,切断电路。此外,800V交流塑壳断路器还配备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 特点 800V交流塑壳断路器具有多项重要特点: 可靠性:这些断路器经过严格的测试和质量控制,具有卓越的可靠性,能够长期保持稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,满足多种应用场合的要求。 高性能:800V交流塑壳断路器通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些800V交流塑壳断路器具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 800V交流塑壳断路器在多个应用领域中发挥着关键作用: 工业领域:在工厂和制造业中,800V交流塑壳断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力设备和电路需要可靠的保护,800V交流塑壳断路器确保了电力系统的可靠性。 能源分配:这些断路器用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,800V交流塑壳断路器在太阳能和风能系统中起到关键作用,保护这些系统免受电力波动和故障的影响。 电力系统的卫士 总之,800V交流塑壳断路器被视为电力系统的卫士。它们通过可靠的工作原理和多种特点,保护了电力设备、电线路和人员的安全。800V交流塑壳断路器的重要性在于,它们能够及时切断电路,防止电流过载、短路和火灾等电气故障的发生。因此,在设计和维护电力系统时,选择适当类型和高质量的800V交流塑壳断路器至关重要,以确保电力供应的可靠性和安全性。在电力系统中,800V交流塑壳断路器是一位不可或缺的卫士,为我们的电力世界提供了稳定、可靠和安全的电力保护。 标题:1000A框架断路器:电力安全的卫士 1000A框架断路器作为电力系统中的关键组件,扮演着保护电路和设备安全运行的关键角色。本文将深入探讨1000A框架断路器的工作原理、特点、应用领域以及在电力安全中的不可或缺之处。 工作原理 1000A框架断路器是一种电气开关设备,用于在电路中断开电流流动,以保护电力系统、设备和人员的安全。其工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会被激活,导致断路器自动跳闸,切断电路。此外,1000A框架断路器还装备了热保护装置,可以监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 特点 1000A框架断路器具有多项重要特点: 可靠性:这些断路器经过严格的测试和质量控制,具有卓越的可靠性,能够长期稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,满足多种应用场合的要求。 高性能:1000A框架断路器通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些1000A框架断路器具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 1000A框架断路器在多个领域中广泛应用: 工业生产:在工厂和制造业中,这些断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力系统需要高度可靠性,1000A框架断路器用于保护电路和设备,确保电力系统的可靠性。 能源分配:它们用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,如太阳能和风能,1000A框架断路器在这些系统中发挥关键作用,保护电力传输的安全性和可靠性。 电力安全的卫士 总之,1000A框架断路器被认为是电力系统的卫士,通过其高可靠性、灵活性和高性能,保护了电力设备、电线路和人员的安全。它们在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和稳定性。因此,在设计和维护电力系统时,选择和维护1000A框架断路器都至关重要,以确保电力安全和电力系统的可靠性。这些断路器不仅是电力系统的卫士,也是电力安全的坚实保障,为我们的电力世界提供了稳定、可靠和安全的电力保护。 标题:3级框架断路器:电力安全的守护者 3级框架断路器,作为电力系统的关键组件,扮演着保护电路和设备安全运行的关键角色。本文将深入探讨3级框架断路器的工作原理、特点、应用领域以及在电力安全中的不可或缺之处。 工作原理 3级框架断路器是一种电气开关设备,通常用于低电压电力系统,其工作原理基于电磁触发器和热保护机制。当电流超过额定值或电路发生故障时,断路器内部的电磁触发器会被激活,导致断路器自动跳闸,切断电路。此外,3级框架断路器还装备了热保护装置,可监测电路中的温度,一旦温度升高到危险水平,也会触发断路器,以防止过载和火灾。 特点 3级框架断路器具备多项重要特点: 可靠性:这些断路器经过严格的测试和质量控制,具有卓越的可靠性,能够长期稳定工作。 灵活性:它们具有可调的短路保护设置,可适应不同电流需求,满足多种应用场合的要求。 高性能:3级框架断路器通常具有快速的中断能力,可以在电流超出安全范围时迅速切断电路,确保设备和人员的安全。 自动复位:一些3级框架断路器具备自动复位功能,一旦电路问题解决,它们可以自动闭合电路,减少维护工作。 应用领域 3级框架断路器在多个领域中广泛应用: 工业生产:在工厂和制造业中,这些断路器用于保护重要的生产设备,确保生产的连续性和稳定性。 商业建筑:商业建筑中的电力系统需要高度可靠性,3级框架断路器用于保护电路和设备,确保电力系统的可靠性。 能源分配:它们用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:随着可再生能源的增加,如太阳能和风能,3级框架断路器在这些系统中发挥关键作用,保护电力传输的安全性和可靠性。 电力安全的守护者 总之,3级框架断路器被认为是电力系统的守护者,通过其高可靠性、灵活性和高性能,保护了电力设备、电线路和人员的安全。它们在防止电路过载、短路和火灾等方面发挥了不可或缺的作用,确保了电力供应的连续性和稳定性。因此,在设计和维护电力系统时,选择和维护3级框架断路器都至关重要,以确保电力安全和电力系统的可靠性。这些断路器不仅是电力系统的守护者,也是电力安全的坚实保障,为我们的电力世界提供了稳定、可靠和安全的电力保护。 标题:MCCB冲制五金零部件定制:电力系统的精密保障 随着电力系统的不断发展,对于电路保护和电流控制的需求也越来越高。MCCB(Molded Case Circuit Breaker)作为关键的电气元件,起到了保护电路和设备的重要作用。本文将深入探讨MCCB冲制五金零部件定制的重要性、定制流程、特点以及应用领域。 定制的重要性 MCCB是电力系统中的关键组件,通常用于保护电路免受过载和短路等故障的影响。为了确保MCCB的可靠性和性能,冲制五金零部件的定制变得至关重要。每个电力系统可能都具有不同的要求和环境条件,因此,定制的冲制五金零部件可以确保MCCB与特定系统完美匹配,提供最佳的电流控制和保护。 定制流程 MCCB冲制五金零部件的定制流程包括以下步骤: 需求分析:首先,需要与客户充分沟通,了解他们的电力系统需求和特殊要求。这包括电流容量、额定电压、环境条件等。 设计与工程:基于客户的需求,工程师们将开始设计定制的冲制五金零部件。这可能包括特殊的接线配置、材料选择和外部涂层等。 制造与加工:一旦设计完成,制造过程将开始。这包括材料切割、成型、加工和组装,确保每个零部件都符合高质量标准。 测试与质量控制:定制的冲制五金零部件将会经过严格的测试,以确保其性能和可靠性。这包括电流负载测试、环境耐受性测试等。 交付与安装:最后,定制的冲制五金零部件将交付给客户,进行安装和集成到他们的电力系统中。 定制特点 MCCB冲制五金零部件的定制具有以下特点: 精确适配:定制零部件可以精确适配特定的MCCB型号和电力系统要求,确保最佳性能。 提高可靠性:通过定制,可以提高MCCB的可靠性,降低故障风险,延长设备寿命。 适应特殊环境:一些电力系统工作在特殊的环境条件下,定制零部件可以确保MCCB在极端温度、湿度或化学环境下正常运行。 应用领域 MCCB冲制五金零部件定制广泛应用于以下领域: 工业生产:在工业自动化系统中,MCCB需要适应各种电力需求和环境条件。 商业建筑:商业建筑的电力系统需要高度可靠性,定制零部件确保了电力系统的稳定性。 能源分配:用于电能分配系统,确保电力从发电站到终端用户的传输安全可靠。 可再生能源:定制零部件用于太阳能和风能系统,以适应可再生能源的特殊要求。 电力系统的精密保障 总之,MCCB冲制五金零部件的定制为电力系统提供了精密的保障。通过定制,MCCB可以适应各种电力需求和环境条件,提高了电力系统的可靠性和性能。因此,在选择MCCB时,考虑定制冲制五金零部件是确保电力系统安全和持续性的关键步骤。这些定制零部件不仅是电力系统的精密保障,也是电力系统优化的一部分,为我们的电力世界提供了更高水平的电力保护和控制。 Title: “China Frame Circuit Breaker Fixed Switch Manufacturer: Leading the Way in Electrical Safety” In the realm of electrical systems and power distribution, the importance of reliable and efficient circuit breakers cannot be overstated. Among the leading manufacturers in this field is a group of Chinese companies specializing in frame circuit breaker fixed switches. This article will delve into the significance of these manufacturers, their key attributes, and their contributions to electrical safety. Pioneering Electrical Safety China’s frame circuit breaker fixed switch manufacturers have been at the forefront of advancing electrical safety globally. Their products serve as crucial components within electrical distribution systems, protecting circuits, devices, and, most importantly, human lives from the hazards of electrical faults. These manufacturers have played a pivotal role in making electrical systems safer and more efficient. Manufacturing Excellence One of the standout features of these manufacturers is their commitment to manufacturing excellence. They adhere to stringent quality control standards, ensuring that their frame circuit breaker fixed switches are not only reliable but also durable. Rigorous testing and inspection processes are employed to guarantee that each product meets or exceeds international safety standards. Customization Capabilities China’s frame circuit breaker fixed switch manufacturers understand that electrical systems vary widely in terms of specifications and requirements. To cater to this diversity, they offer customization services. Clients can work closely with these manufacturers to tailor switches to their specific needs, taking into account factors such as voltage capacity, environmental conditions, and application particulars. This ability to adapt makes them invaluable partners across various industries. Versatile Applications The products from these manufacturers find applications across a broad spectrum of industries: Industrial Settings: In factories and manufacturing plants, frame circuit breaker fixed switches protect vital production equipment, ensuring continuity and stability in manufacturing processes. Commercial Buildings: Reliable power is essential for commercial buildings. These switches help safeguard circuits and equipment, ensuring the reliability of electrical systems in such settings. Power Distribution: These switches are crucial in electrical energy distribution systems, ensuring the safe and efficient transfer of power from generation stations to end-users. Renewable Energy: As renewable energy sources like solar and wind power gain prominence, frame circuit breaker fixed switches play a vital role in safeguarding these systems against electrical faults. Contributing to Global Electrical Safety China’s frame circuit breaker fixed switch manufacturers have significantly contributed to global electrical safety. Their commitment to excellence, coupled with their customization capabilities and versatile applications, has made them trusted partners in industries worldwide. By ensuring the reliability and safety of electrical systems, they play a vital role in preventing electrical accidents and disruptions. Conclusion In conclusion, China’s frame circuit breaker fixed switch manufacturers are at the forefront of electrical safety innovation. Their dedication to producing high-quality, customizable, and versatile products has earned them a well-deserved reputation as leaders in the field. As the world’s electrical systems continue to evolve and expand, these manufacturers will remain essential partners in maintaining the safety and reliability of electrical power distribution. Their contributions not only benefit the industries they serve but also enhance electrical safety globally. Title: “China Molded Case Circuit Breaker ODM Manufacturer: Shaping the Future of Electrical Safety” The landscape of electrical systems and power distribution relies heavily on the role of Molded Case Circuit Breakers (MCCBs). Among the prominent players in this arena are Chinese manufacturers specializing in MCCB Original Design Manufacturing (ODM). This article delves into the significance of these ODM manufacturers, their distinctive attributes, and their contributions to enhancing electrical safety. Shaping the Electrical Safety Landscape Chinese MCCB ODM manufacturers have been instrumental in shaping and advancing electrical safety on a global scale. Their products serve as vital components in electrical distribution systems, providing protection against electrical faults, safeguarding equipment, and, most importantly, ensuring the safety of individuals. These manufacturers have played a pivotal role in making electrical systems safer, more efficient, and more adaptable to evolving needs. Innovative ODM Solutions One of the standout features of these manufacturers is their commitment to innovation and original design. They possess the capability to create MCCBs tailored to specific requirements, thanks to their in-house research and development teams. This flexibility allows them to address unique challenges and to stay at the forefront of technological advancements in the field of electrical safety. Customization Expertise China’s MCCB ODM manufacturers understand that electrical systems come in various configurations and specifications. They offer comprehensive customization services, enabling clients to collaborate closely with them in designing MCCBs that meet their precise needs. Whether it’s voltage ratings, current capacities, or specialized applications, these manufacturers have the expertise to create tailored solutions. Global Reach The products from these manufacturers find applications worldwide: Industrial Applications: In industrial settings, MCCBs are pivotal in protecting critical production equipment, ensuring manufacturing processes continue without disruptions. Commercial and Residential Buildings: Reliable power is paramount for both commercial and residential structures. MCCBs help secure circuits and equipment, ensuring dependable electrical systems. Power Distribution: These MCCBs play a crucial role in electrical energy distribution systems, guaranteeing the safe and efficient transmission of power from generation facilities to end-users. Renewable Energy: With the rise of renewable energy sources such as solar and wind power, MCCBs are essential components in safeguarding these systems from electrical faults. Global Impact on Electrical Safety China’s MCCB ODM manufacturers have had a substantial impact on enhancing global electrical safety. Their focus on innovation, combined with their extensive customization capabilities and versatile applications, positions them as trusted partners across industries worldwide. By ensuring the reliability and safety of electrical systems, they play a vital role in preventing electrical accidents and disruptions. The Future of Electrical Safety In conclusion, China’s MCCB ODM manufacturers are at the forefront of shaping the future of electrical safety. Their commitment to original design, flexibility, and adaptability make them indispensable contributors to the evolving landscape of electrical systems. As electrical technology continues to advance and diversify, these manufacturers will remain pivotal in maintaining and improving the safety and reliability of power distribution. Their contributions extend beyond industry borders, benefiting global electrical safety standards and practices. Title: “China’s Universal Circuit Breaker Manufacturer: Pioneering Electrical Safety Worldwide” In the ever-evolving realm of electrical systems and power distribution, universal circuit breakers stand as essential guardians of electrical safety. Among the prominent players in this field are Chinese manufacturers specializing in universal circuit breakers. This article explores the significance of these manufacturers, their key attributes, and their contributions to electrical safety on a global scale. Leading the Charge in Electrical Safety Chinese universal circuit breaker manufacturers have emerged as trailblazers in the quest for enhanced electrical safety worldwide. Their products serve as critical components within electrical distribution systems, shielding circuits, devices, and most importantly, human lives from the perils of electrical faults. These manufacturers have played an instrumental role in elevating the safety and efficiency of electrical systems. Commitment to Quality One of the distinguishing features of these manufacturers is their unwavering commitment to quality. They adhere to rigorous quality control standards, ensuring that their universal circuit breakers are not only reliable but also durable. Stringent testing and inspection procedures are employed to ensure that each product meets or exceeds international safety norms. Versatile and Customizable Solutions Chinese universal circuit breaker manufacturers recognize the diversity of electrical systems and applications. To cater to this diversity, they offer versatile and customizable solutions. Clients can collaborate closely with these manufacturers to tailor circuit breakers to their specific needs, accounting for factors such as voltage ratings, current capacities, and specialized applications. This adaptability makes them invaluable partners across various industries. Wide-Ranging Applications Products from these manufacturers find applications across a wide spectrum of industries: Industrial Environments: In factories and manufacturing plants, universal circuit breakers protect vital production equipment, ensuring the continuity and stability of manufacturing processes. Commercial and Residential Structures: In commercial and residential buildings, these circuit breakers safeguard circuits and equipment, ensuring the reliability of electrical systems. Power Distribution: These circuit breakers play a crucial role in electrical energy distribution systems, ensuring the safe and efficient transmission of power from generation facilities to end-users. Renewable Energy: With the growing adoption of renewable energy sources such as solar and wind power, universal circuit breakers are indispensable in safeguarding these systems against electrical faults. Global Contributions to Electrical Safety Chinese universal circuit breaker manufacturers have made significant contributions to enhancing electrical safety on a global scale. Their dedication to excellence, coupled with their customization capabilities and versatile applications, has established them as trusted partners in industries worldwide. By ensuring the reliability and safety of electrical systems, they play a pivotal role in preventing electrical accidents and disruptions. Conclusion In conclusion, China’s universal circuit breaker manufacturers are pioneering leaders in the pursuit of enhanced electrical safety. Their dedication to quality, adaptability, and versatility positions them as indispensable contributors to the evolving landscape of electrical systems. As electrical technology continues to advance and diversify, these manufacturers will remain at the forefront of maintaining and enhancing the safety and reliability of power distribution. Their contributions extend far beyond industry boundaries, benefiting global electrical safety standards and practices. Title: “DC Molded Case Circuit Breaker Manufacturers: Pioneering Electrical Safety in the Modern World” In today’s rapidly advancing world of electrical systems and power distribution, the role of DC Molded Case Circuit Breakers (MCCBs) is becoming increasingly critical. Among the leading innovators in this specialized field are DC MCCB manufacturers. This article delves into the significance of these manufacturers, their distinctive qualities, and their vital contributions to modern electrical safety. Leading the Charge in Electrical Safety DC MCCB manufacturers from around the world, with a notable presence in China, have emerged as pioneers in advancing electrical safety to new heights. Their products serve as essential components within electrical distribution systems, providing the crucial function of safeguarding circuits, equipment, and, most importantly, human lives from the hazards of electrical faults. These manufacturers are at the forefront of making electrical systems safer, more efficient, and adaptable to the evolving needs of industries. Commitment to Quality One of the standout features of these manufacturers is their unwavering commitment to quality. They adhere to strict quality control standards, ensuring that their DC MCCBs are not only reliable but also exceptionally durable. Rigorous testing and thorough inspection procedures are integral to their production process, ensuring that each product complies with or surpasses international safety standards. Innovative and Specialized Solutions DC MCCB manufacturers are known for their capacity to provide innovative and specialized solutions. Their dedicated research and development teams work tirelessly to create MCCBs tailored to unique requirements. This flexibility allows them to address specific challenges and stay at the forefront of technological advancements in the realm of electrical safety. Customization Expertise These manufacturers understand the wide-ranging diversity of electrical systems and applications. They offer comprehensive customization services, enabling clients to collaborate closely with them to design MCCBs that precisely meet their needs. These customized solutions account for factors such as voltage ratings, current capacities, environmental conditions, and specialized applications, making them invaluable partners across a multitude of industries. Diverse Applications The products from DC MCCB manufacturers find applications across a broad spectrum of industries: Industrial Applications: In manufacturing plants and factories, DC MCCBs protect critical production equipment, ensuring the continuity and stability of manufacturing processes. Commercial and Residential Structures: In commercial and residential buildings, these circuit breakers secure circuits and equipment, ensuring the reliability of electrical systems. Power Distribution: DC MCCBs play a vital role in electrical energy distribution systems, guaranteeing the safe and efficient transmission of power from generation facilities to end-users. Renewable Energy: As the adoption of renewable energy sources like solar and wind power continues to rise, DC MCCBs become indispensable in safeguarding these systems against electrical faults. Global Impact on Electrical Safety DC MCCB manufacturers have had a substantial impact on enhancing electrical safety globally. Their emphasis on innovation, combined with their extensive customization capabilities and versatile applications, positions them as trusted partners across industries worldwide. By ensuring the reliability and safety of electrical systems, they play a pivotal role in preventing electrical accidents and disruptions. Conclusion In conclusion, DC MCCB manufacturers are pioneering leaders in the pursuit of enhanced electrical safety in the modern world. Their dedication to quality, adaptability, and innovation makes them indispensable contributors to the ever-evolving landscape of electrical systems. As electrical technology continues to advance and diversify, these manufacturers will remain at the forefront of maintaining and enhancing the safety and reliability of power distribution. Their contributions extend far beyond industry boundaries, positively impacting global electrical safety standards and practices. Title: “Empowering Electrical Safety: Frame Circuit Breaker Drawer Switch ODM Manufacturers” In the dynamic landscape of electrical systems and power distribution, Frame Circuit Breaker Drawer Switches play a pivotal role in ensuring the safety and reliability of electrical circuits. Behind the innovation and manufacturing of these critical components are Frame Circuit Breaker Drawer Switch ODM (Original Design Manufacturer) companies. This article explores the significance of these ODM manufacturers, their unique attributes, and their contributions to advancing electrical safety. Driving Electrical Safety Forward Frame Circuit Breaker Drawer Switch ODM manufacturers are at the forefront of advancing electrical safety globally. Their products are integral to electrical distribution systems, providing essential protection against overloads, short circuits, and other electrical faults. These manufacturers are dedicated to making electrical systems safer, more efficient, and better tailored to meet the diverse needs of various industries. A Commitment to Innovation One of the standout features of these ODM manufacturers is their unwavering commitment to innovation. They invest heavily in research and development, enabling them to create cutting-edge solutions in electrical safety. Their ability to design original components sets them apart and ensures they remain on the leading edge of technology in the electrical safety sector. Customization Expertise Frame Circuit Breaker Drawer Switch ODM manufacturers understand the diverse requirements of electrical systems. They offer extensive customization services, allowing clients to collaborate closely with them to design switch solutions that precisely align with their unique needs. These custom solutions account for factors such as voltage ratings, current capacities, environmental conditions, and specialized applications, making these manufacturers invaluable partners across various industries. Quality Assurance These manufacturers adhere to rigorous quality control standards, ensuring their products are not only reliable but also highly durable. Stringent testing and thorough inspection procedures are integral to their production processes, guaranteeing that each product complies with or surpasses international safety and quality standards. Diverse Applications Products from Frame Circuit Breaker Drawer Switch ODM manufacturers find applications across a wide range of industries: Industrial Applications: In manufacturing plants and factories, these switches protect critical production equipment, ensuring uninterrupted manufacturing processes. Commercial and Residential Buildings: In commercial and residential structures, these switches secure circuits and equipment, ensuring the reliability of electrical systems. Power Distribution: These switches play a vital role in electrical energy distribution systems, guaranteeing the safe and efficient transmission of power from generation facilities to end-users. Renewable Energy: With the growing adoption of renewable energy sources such as solar and wind power, Frame Circuit Breaker Drawer Switches become indispensable in safeguarding these systems against electrical faults. Global Impact on Electrical Safety Frame Circuit Breaker Drawer Switch ODM manufacturers have made significant contributions to enhancing global electrical safety. Their dedication to innovation, combined with their extensive customization capabilities and versatile applications, positions them as trusted partners across industries worldwide. By ensuring the reliability and safety of electrical systems, they play a pivotal role in preventing electrical accidents and disruptions. Conclusion In conclusion, Frame Circuit Breaker Drawer Switch ODM manufacturers are driving forces in advancing electrical safety in the modern world. Their commitment to innovation, adaptability, and customization makes them indispensable contributors to the ever-evolving landscape of electrical systems. As electrical technology continues to advance and diversify, these manufacturers will remain at the forefront of maintaining and enhancing the safety and reliability of power distribution. Their contributions extend far beyond industry boundaries, positively impacting global electrical safety standards and practices. Title: “Precision and Innovation: The World of Injection Molded Parts Manufacturers” In the realm of manufacturing and production, Injection Molded Parts Manufacturers stand as essential pillars of innovation and precision. This article will delve into the significance of these manufacturers, their key attributes, and their contributions to various industries worldwide. Leading the Industry with Precision Injection molded parts manufacturers are pivotal in the manufacturing landscape, creating components with a level of precision that is hard to match. Their expertise lies in utilizing injection molding technology, which allows them to produce intricate and complex parts with consistency and accuracy. This precision is crucial for a wide range of industries, from automotive to electronics. Versatility in Materials One of the standout features of these manufacturers is their versatility in materials. They can work with a wide array of materials, including plastics, metals, and composites, depending on the requirements of the project. This flexibility makes them indispensable across various sectors, enabling them to create components that meet specific needs, whether it’s for durability, conductivity, or weight savings. Innovation and Design Injection molded parts manufacturers are often at the forefront of innovation and design. They employ highly skilled engineers and designers who can optimize parts for functionality and cost-effectiveness. Their ability to create custom solutions allows them to develop parts that are tailor-made for the unique needs of their clients. Sustainable Practices In recent years, sustainability has become a key focus for many manufacturers. Injection molded parts manufacturers have responded by adopting environmentally friendly practices. Many use recyclable materials and implement energy-efficient manufacturing processes. This commitment to sustainability not only benefits the environment but also aligns with the evolving demands of conscious consumers and regulations. Wide Applications The products from these manufacturers find applications across a broad spectrum of industries: Automotive: Injection molded parts are widely used in the automotive industry for components such as interior panels, dashboards, and engine parts. Electronics: The electronics industry relies on these manufacturers for producing precision parts for devices, connectors, and casings. Medical: In the medical sector, injection molded parts are crucial for creating sterile and precise components for equipment and devices. Consumer Goods: Many everyday items, from toys to household appliances, are made with injection molded parts. Global Reach Injection molded parts manufacturers often serve international markets. They are capable of producing components that adhere to various industry standards and regulations, making them valuable partners for global corporations and startups alike. The Future of Manufacturing In conclusion, Injection Molded Parts Manufacturers play an essential role in the world of manufacturing and production. Their precision, versatility, and commitment to innovation make them integral partners across a wide range of industries. As technology continues to evolve and consumer demands change, these manufacturers will continue to be at the forefront of developing solutions that drive innovation and meet the ever-growing demands of the modern world. Whether it’s creating components for cars, electronics, medical devices, or consumer goods, these manufacturers are shaping the future of manufacturing through their dedication to precision and innovation.