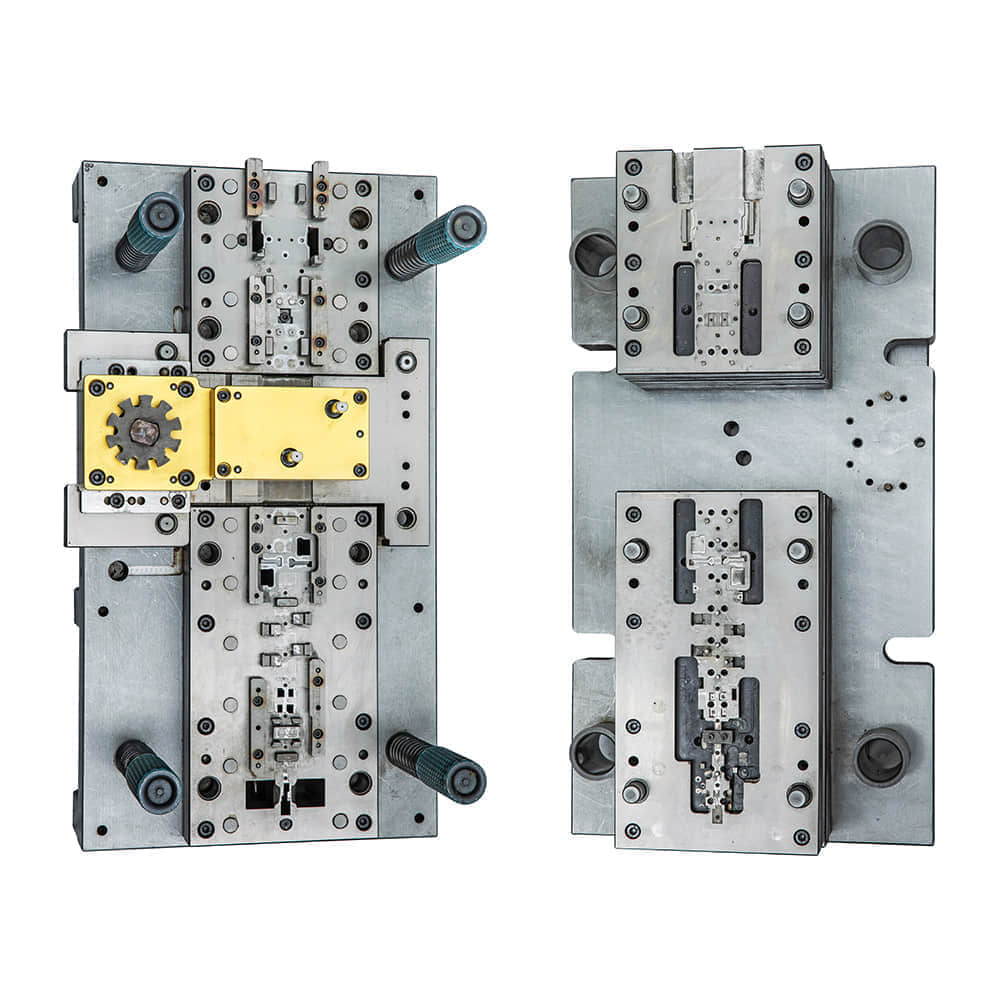

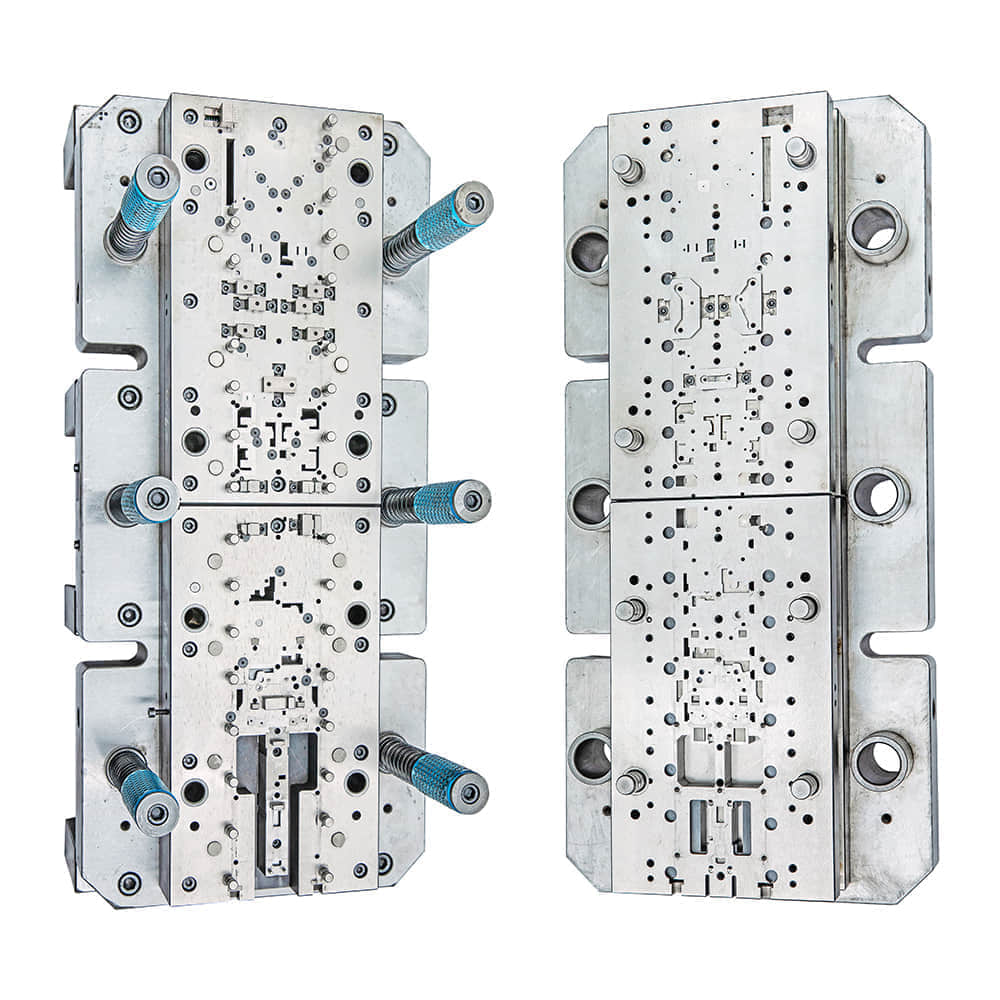

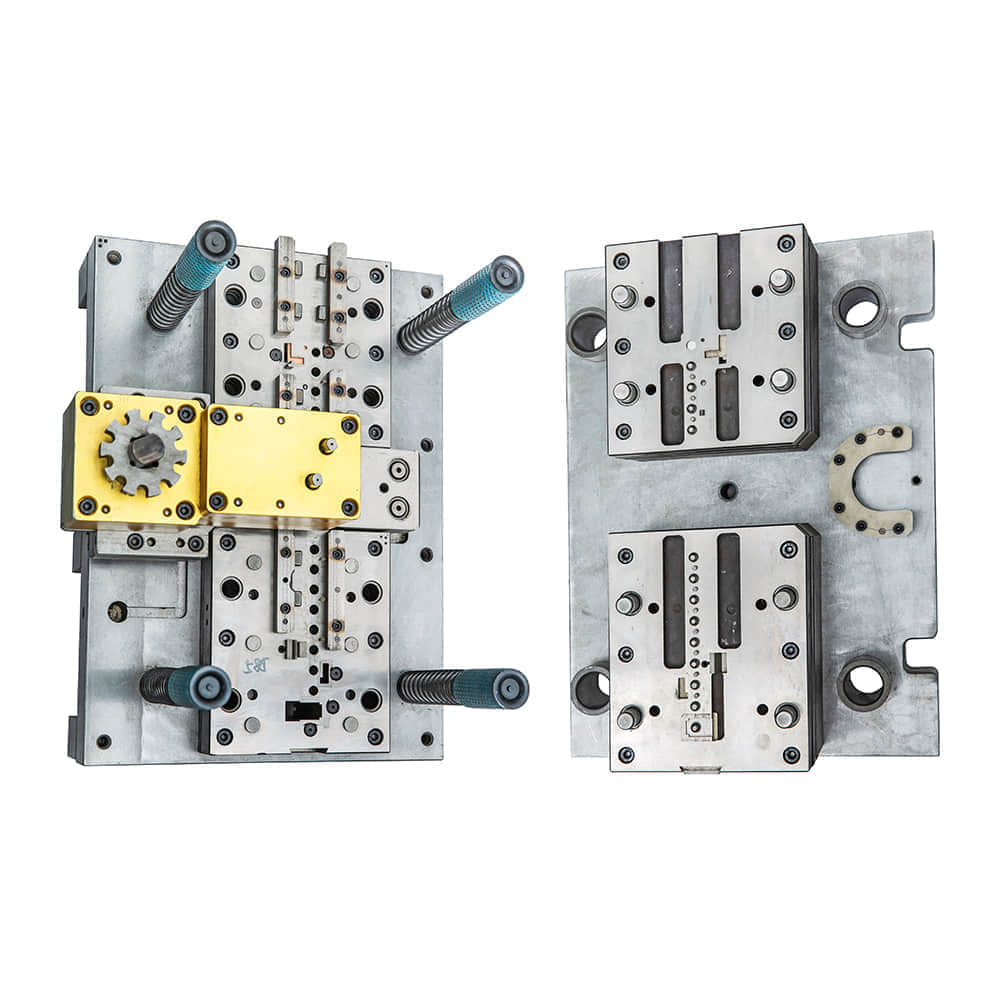

In the heart of the global manufacturing hub, China has emerged as a powerhouse in metalworking industries. Among the various sectors contributing to China’s industrial prowess, metal stamping stands out as a cornerstone. As the demand for precision parts and components continues to rise worldwide, China’s metal stamping die manufacturers have become leaders in the field, consistently delivering high-quality products and innovative solutions.

China’s Rise in Metal Stamping Die Manufacturing

Over the past few decades, China has made remarkable strides in the field of metal stamping die manufacturing. The industry has evolved from basic die-cutting operations to highly specialized and technologically advanced processes. This transformation has been driven by a combination of factors, including investment in research and development, access to skilled labor, and a deep commitment to quality. State-of-the-Art Technology China’s metal stamping die manufacturers have embraced cutting-edge technology to stay ahead in the global market. Advanced CAD/CAM software and CNC machining have enabled them to create intricate, precise, and complex dies for various applications. These innovations have not only improved product quality but also reduced lead times, making China a preferred destination for businesses seeking timely solutions. Quality Assurance Quality is paramount in metal stamping die manufacturing, and Chinese companies understand this better than anyone. They adhere to international standards and certifications, ensuring that their products meet or exceed customer expectations. Rigorous quality control measures, such as inspection and testing, are integral parts of their manufacturing processes, guaranteeing consistent excellence. Cost-Efficiency and Competitive Pricing China’s metal stamping die manufacturers have mastered the art of cost-efficiency. Leveraging economies of scale, they can offer competitive pricing without compromising on quality. This cost-effectiveness has made Chinese manufacturers attractive partners for businesses worldwide, particularly in industries requiring large volumes of stamped components. Global Reach China’s metal stamping die manufacturers have expanded their global footprint. They have established strong networks and partnerships across borders, allowing them to provide seamless service to clients around the world. This global reach enables them to adapt to diverse market needs and offer personalized solutions. Customization and Flexibility Versatility is a hallmark of China’s metal stamping die manufacturers. They can produce a wide range of dies tailored to specific customer requirements. Whether it’s automotive parts, electronics, or aerospace components, these manufacturers excel in providing customized solutions that cater to the unique demands of each industry. Sustainability In line with global efforts to reduce environmental impact, Chinese metal stamping die manufacturers are increasingly adopting sustainable practices. They prioritize the use of eco-friendly materials, energy-efficient processes, and waste reduction measures. This commitment to sustainability not only benefits the environment but also aligns with the preferences of environmentally conscious customers. Innovation and Research The Chinese metal stamping die industry is not content with past achievements; it is constantly pushing the boundaries of innovation. Investing in research and development, these manufacturers are at the forefront of creating new techniques and materials to enhance the performance and longevity of their dies. Conclusion China’s metal stamping die manufacturers have risen to prominence through their dedication to quality, technological prowess, and cost-effectiveness. With a global presence, a commitment to sustainability, and an unwavering focus on innovation, they are poised to continue leading the way in the metalworking industry. As the demand for precision components grows, these manufacturers stand ready to meet the evolving needs of customers worldwide, solidifying their reputation as industry leaders.