Introduction

Blanking dies are a fundamental tool in the realm of manufacturing and metalworking. They play a crucial role in shaping raw materials into precise components used in various industries. This article delves into the world of blanking dies, exploring their functions, types, advancements, and widespread applications.

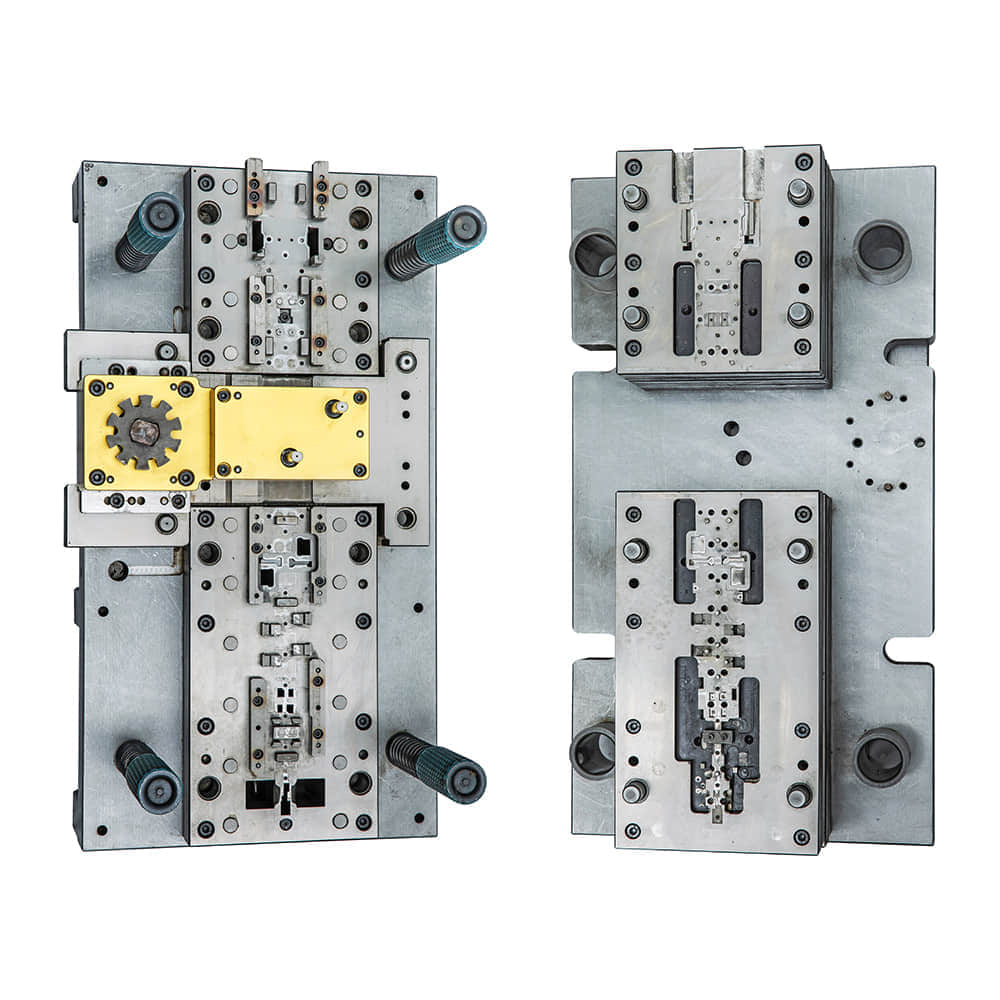

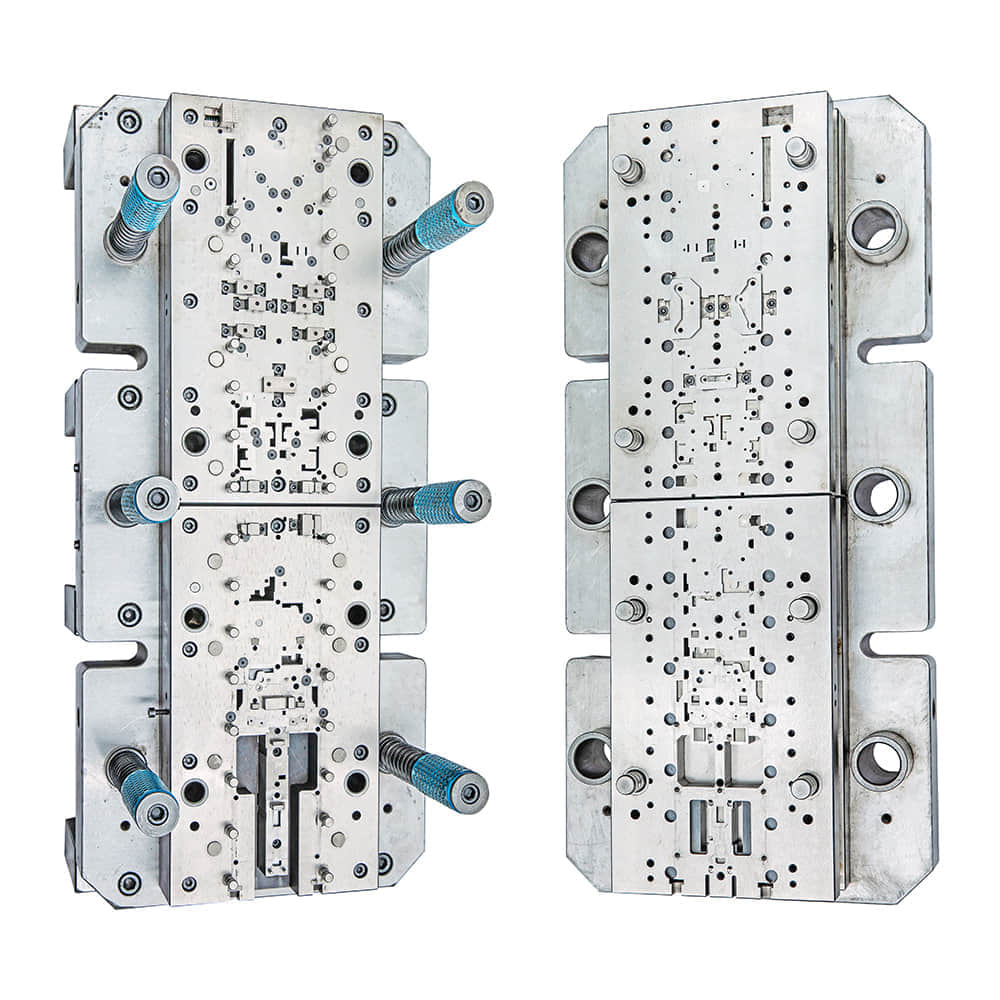

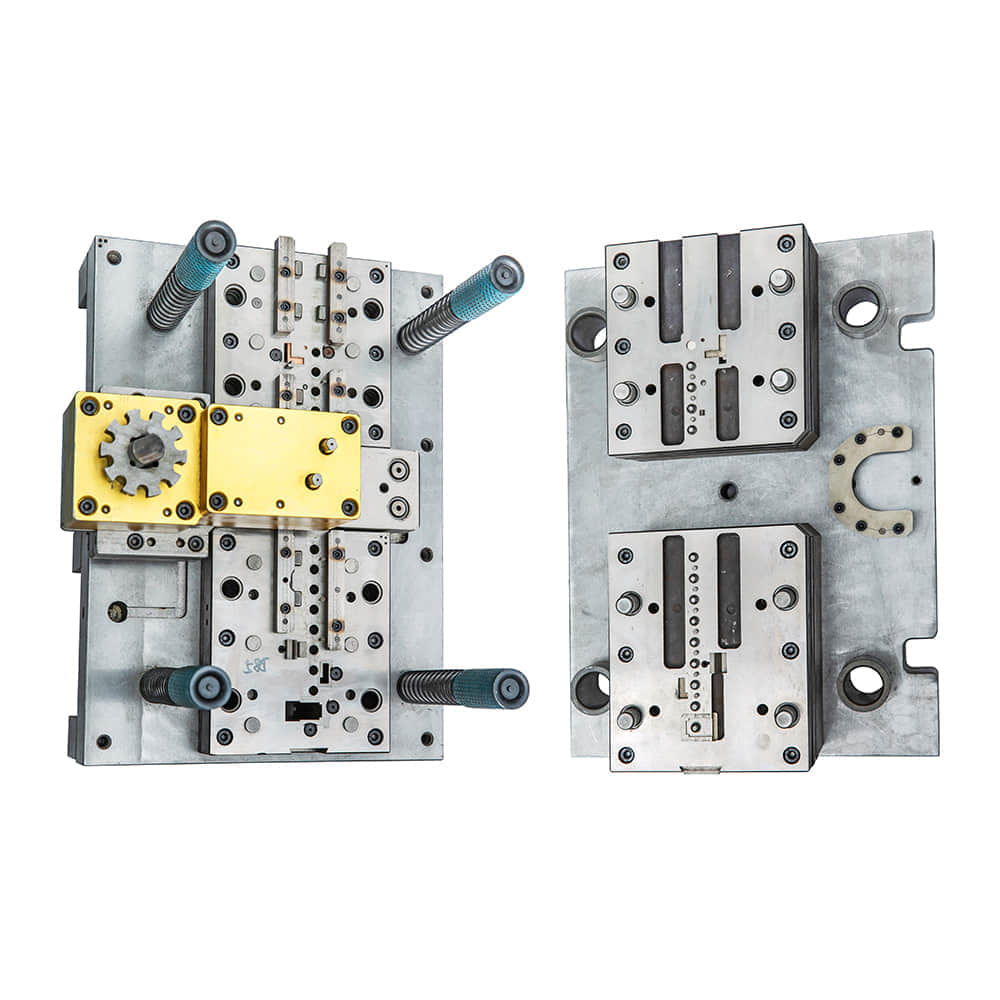

Function of Blanking Dies Blanking dies are specialized cutting tools designed to cut flat shapes from sheet metal or other materials with high precision. The primary function of a blanking die is to create a piece with a desired shape while minimizing waste material. This process involves a combination of cutting, shearing, and punching actions to produce clean-edged components used in the assembly of larger products. Types of Blanking Dies Simple Blanking Dies:These dies involve a single cutting operation to produce a flat shape. They are often used for creating basic components with uncomplicated designs. Compound Blanking Dies:Compound dies perform multiple cutting operations in a single stroke, resulting in more complex shapes with intricate details. This type of die is commonly used for producing components with holes, notches, or other specialized features. Progressive Blanking Dies:Progressive dies consist of a series of stations, each performing a different cutting or forming operation as the material progresses through the die. This allows for the efficient production of parts with multiple features in a continuous process. Pierce-and-Blank Dies:These dies combine the functions of blanking and hole-punching in a single operation. They are used to create components with holes or openings in addition to the main blanked shape. Advancements in Blanking Die Technology In recent years, advancements in manufacturing technology have led to significant improvements in blanking die design and operation: Computer-Aided Design (CAD):CAD software enables engineers to create intricate die designs with high precision. This technology has streamlined the design process, allowing for rapid prototyping and iteration. Computer Numerical Control (CNC) Machining:CNC technology automates the machining process, resulting in more accurate and consistent die components. This leads to enhanced overall die performance and durability. High-Speed Blanking Presses:Modern high-speed presses can perform multiple strokes per second, increasing production rates while maintaining tight tolerances. These presses are crucial for industries requiring high-volume part production. Applications of Blanking Dies Blanking dies find applications across a wide range of industries, including: Automotive:Blanking dies are used to create various components in the automotive industry, such as body panels, brackets, and chassis parts. Consumer Electronics:The production of electronic devices often involves blanking dies to manufacture precise metal or plastic components used in casings, connectors, and internal structures. Aerospace:In aerospace, blanking dies are used to create lightweight yet robust components for aircraft and spacecraft, contributing to improved fuel efficiency and performance. Appliances:Household appliances like refrigerators, ovens, and washing machines utilize blanking dies to manufacture parts that ensure proper functionality and aesthetics. Conclusion Blanking dies are indispensable tools that have revolutionized manufacturing processes across various industries. Through their precise cutting actions and versatility, they enable the creation of intricate components used in countless products. As technology continues to advance, we can expect further refinements in blanking die design and operation, leading to even greater efficiency and accuracy in component production.