Metal Stamping Dies: The Backbone of Precision Manufacturing

In the world of manufacturing, precision is paramount. Whether it’s the creation of intricate automotive parts or the production of delicate electronics, the ability to shape metal with absolute accuracy is essential. This is where metal stamping dies and the manufacturers behind them come into play, serving as the unsung heroes of countless industries. In this article, we’ll delve into the world of metal stamping die manufacturers and their pivotal role in modern manufacturing processes.

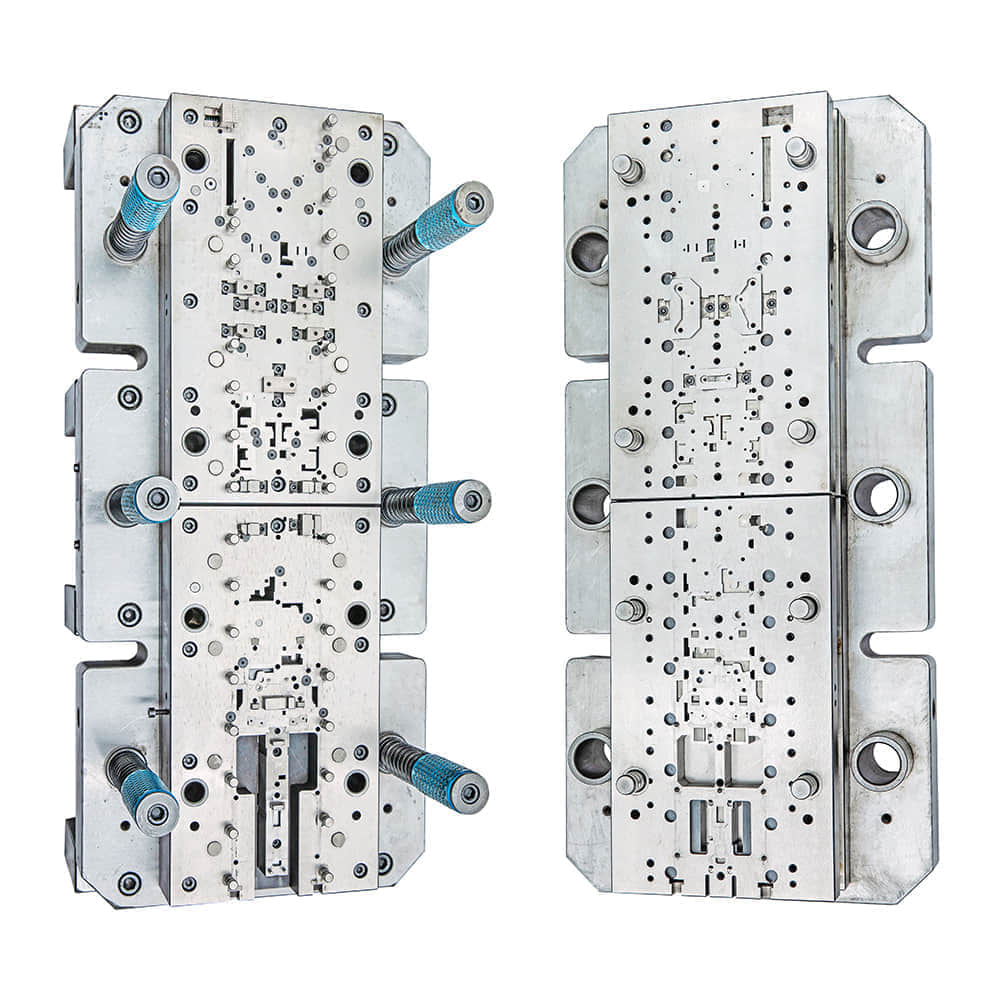

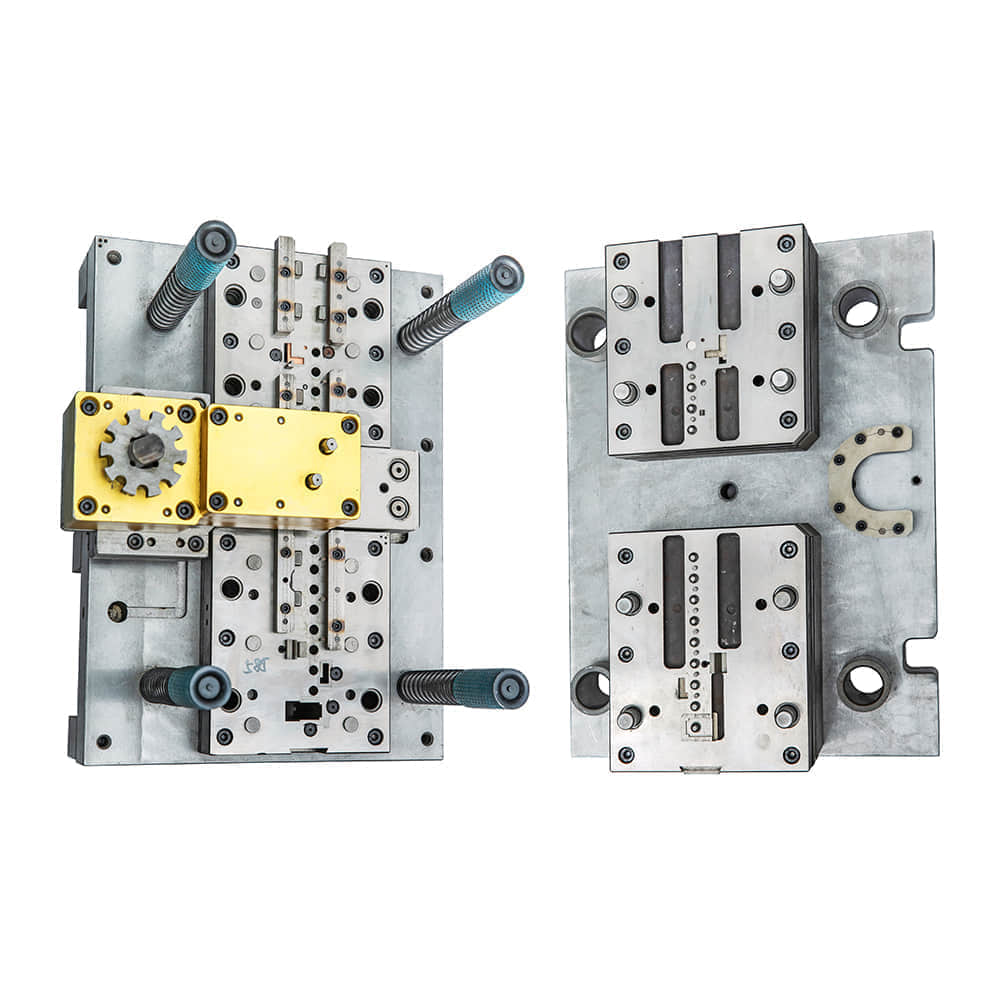

What are Metal Stamping Dies? Before we explore the manufacturers, let’s first understand what metal stamping dies are. Essentially, metal stamping dies are specialized tools used to shape, cut, or deform sheet metal into desired forms. These dies are custom-designed for specific tasks, making them indispensable for producing consistent and precise metal components. The Expertise Behind the Craft Creating metal stamping dies is no ordinary task; it’s an art form. Manufacturers in this field must possess a deep understanding of materials, engineering, and cutting-edge technologies. They are akin to modern-day blacksmiths, meticulously crafting tools that can withstand immense pressure and repetitive use while maintaining exceptional precision. Innovation at Its Core The metal stamping die manufacturing industry is not one to rest on its laurels. Continuous innovation is a driving force, as manufacturers constantly seek to improve their techniques and materials. Cutting-edge software, like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), has revolutionized the design and production process, allowing for even more intricate and accurate dies. Applications Across Industries Metal stamping dies find applications across a wide range of industries. In the automotive sector, they are used to create body panels, engine components, and intricate parts, contributing to both safety and aesthetics. In electronics, these dies enable the production of finely detailed components used in smartphones, laptops, and other devices. Even in the medical field, metal stamping dies play a vital role in manufacturing surgical instruments and implants. Environmental Responsibility Manufacturers in this field also understand the importance of sustainability. Many have adopted eco-friendly practices, such as recycling scrap materials and using energy-efficient production processes. This commitment to environmental responsibility aligns with the growing global focus on sustainable manufacturing practices. Global Reach, Local Impact Metal stamping die manufacturers may have a global reach, but they often have a significant impact on their local communities. These businesses provide jobs, stimulate local economies, and support a skilled workforce. Their commitment to quality extends to their relationships with local suppliers and customers, fostering a sense of trust and collaboration. Challenges and Triumphs Like any industry, metal stamping die manufacturing has its share of challenges. Rapid technological advancements require manufacturers to stay ahead of the curve, investing in employee training and updated machinery. Additionally, global competition demands that these businesses maintain high standards while remaining cost-competitive. However, it’s precisely these challenges that drive innovation and improvement. Manufacturers in this field thrive on overcoming obstacles, and their resilience has been especially evident in recent years. Conclusion In the world of manufacturing, precision is king, and metal stamping die manufacturers are the crown jewel. Their expertise, innovation, and commitment to excellence are the backbone of countless industries, enabling the production of high-quality, intricate metal components that make our modern world possible. As we continue to push the boundaries of what’s possible in manufacturing, we can be certain that metal stamping die manufacturers will lead the way, shaping a future where precision knows no bounds.