Metal stamping is a versatile and essential process in the manufacturing industry, used to create precision components for a wide range of applications. Metal stamping parts manufacturers play a crucial role in this process, delivering high-quality parts that are used in industries such as automotive, electronics, aerospace, and more. In this article, we will delve into the world of metal stamping parts manufacturers, exploring their significance, processes, and the industries they serve.

The Significance of Metal Stamping Parts Manufacturers

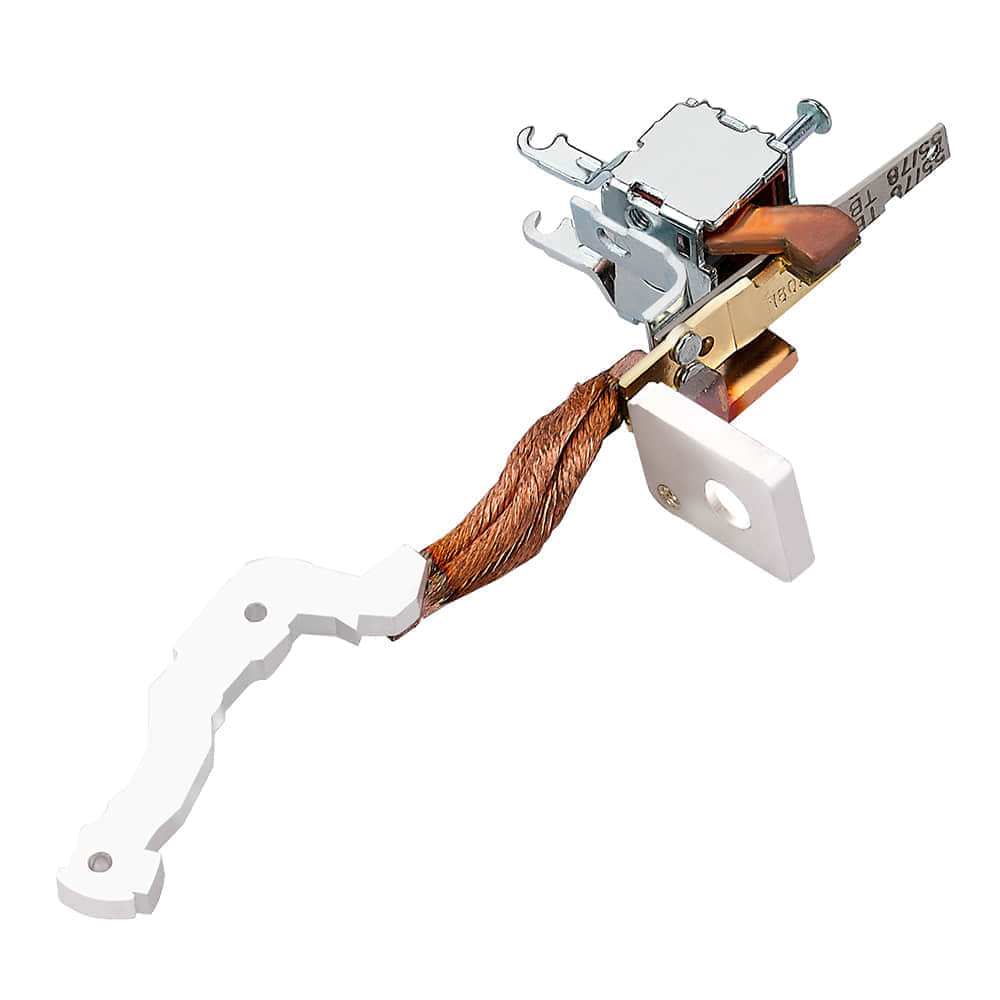

Metal stamping parts manufacturers are at the heart of the manufacturing sector. They specialize in producing components by shaping, cutting, or forming metal sheets or coils through a mechanical press. This process is highly efficient and cost-effective, making it a preferred choice for many industries. One of the key advantages of metal stamping is its ability to produce parts with remarkable precision and consistency. Manufacturers can create intricate designs and complex geometries with tight tolerances, ensuring that the final product meets the exact specifications required for its intended purpose. This precision is vital in industries where safety, reliability, and performance are paramount. The Metal Stamping Process The metal stamping process involves several essential steps, each contributing to the creation of high-quality components: Material Selection: The process begins with selecting the appropriate material, typically metal sheets or coils. The choice of material depends on factors such as strength, corrosion resistance, and cost. Tool and Die Design: Manufacturers design specialized tools and dies that will be used in the stamping process. These tools are tailored to the specific part being produced and are critical in achieving the desired shape and dimensions. Stamping Press Operation: The metal sheet or coil is fed into a stamping press, where it undergoes various operations, including blanking, piercing, bending, and deep drawing. The press exerts high pressure to shape the material according to the die’s specifications. Quality Control: Throughout the process, quality control measures are in place to ensure that each component meets the required standards. Inspections, measurements, and testing help identify and rectify any defects or deviations. Finishing and Assembly: After stamping, the components may undergo finishing processes such as deburring, plating, or coating to enhance their durability and appearance. In some cases, multiple stamped parts are assembled to create a final product. Industries Served by Metal Stamping Parts Manufacturers The versatility of metal stamping makes it indispensable in a wide range of industries: Automotive: Metal stamping parts are integral to the automotive industry, used in vehicle chassis, body panels, and engine components. The high strength and precision of stamped parts contribute to vehicle safety and performance. Electronics: In the electronics sector, metal stamping is used to create components like connectors, brackets, and shielding. These parts are essential for the functioning of various electronic devices and equipment. Aerospace: Aerospace manufacturers rely on metal stamping for aircraft components, including structural parts, fasteners, and instrument panels. The lightweight yet strong properties of stamped metals are ideal for aerospace applications. Medical Devices: Metal stamping plays a crucial role in the production of medical devices, ensuring that they meet stringent quality and safety standards. Components like surgical instruments and implants benefit from the precision of metal stamping. Consumer Goods: Everyday items such as appliances, hardware, and kitchenware often contain stamped metal parts. These components contribute to product functionality and aesthetics. Conclusion Metal stamping parts manufacturers are unsung heroes of the manufacturing world, consistently delivering high-quality, precision components that underpin countless industries. Their expertise in materials, tooling, and quality control ensures that the products we rely on daily meet the highest standards of performance and reliability. As technology advances and industries evolve, metal stamping continues to play a pivotal role in shaping the future of manufacturing.