Injection molding is a pivotal process in modern manufacturing, shaping countless products we encounter daily. Whether it’s the intricate components of your smartphone or the durable plastic casing of your favorite kitchen appliance, injection molding plays a vital role. At the heart of this process are Injection Mold Manufacturers, the unsung heroes of product design and production. In this article, we’ll explore the world of injection mold manufacturers, their techniques, innovations, and the significance of their work.

The Foundation: What is Injection Molding?

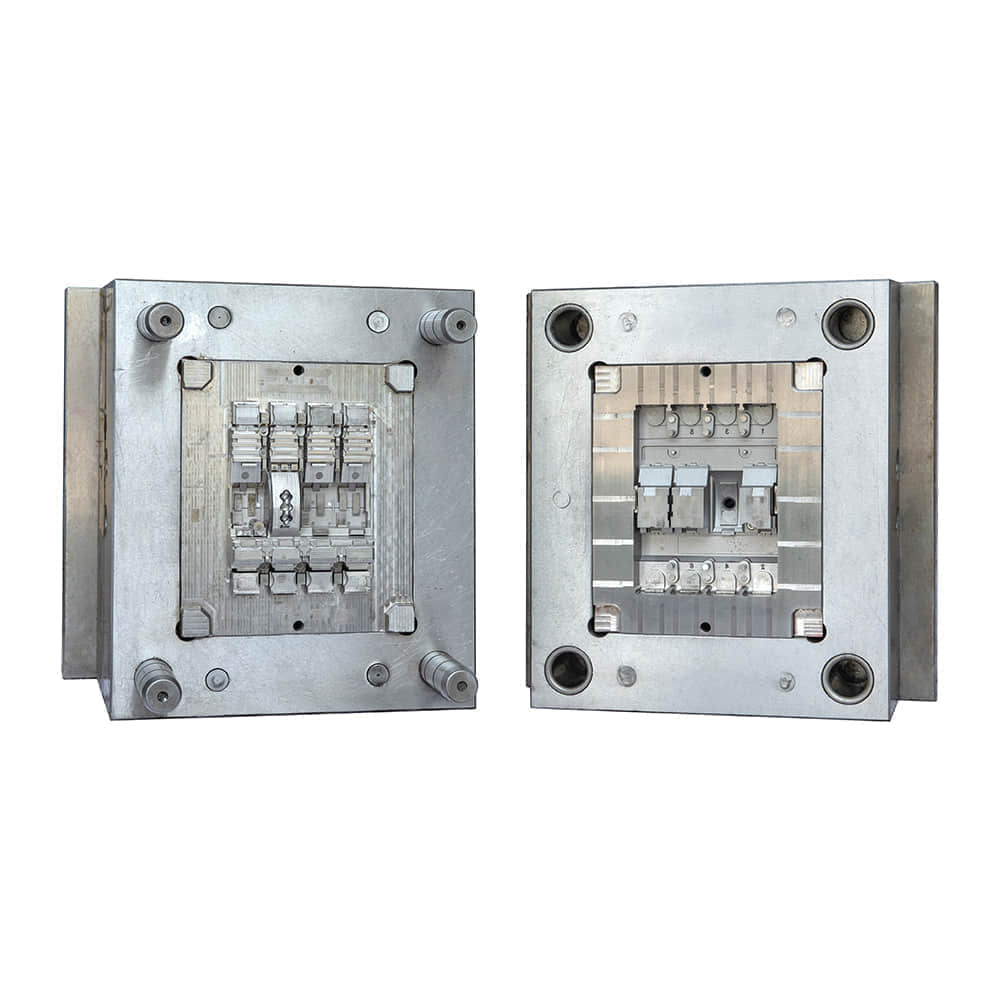

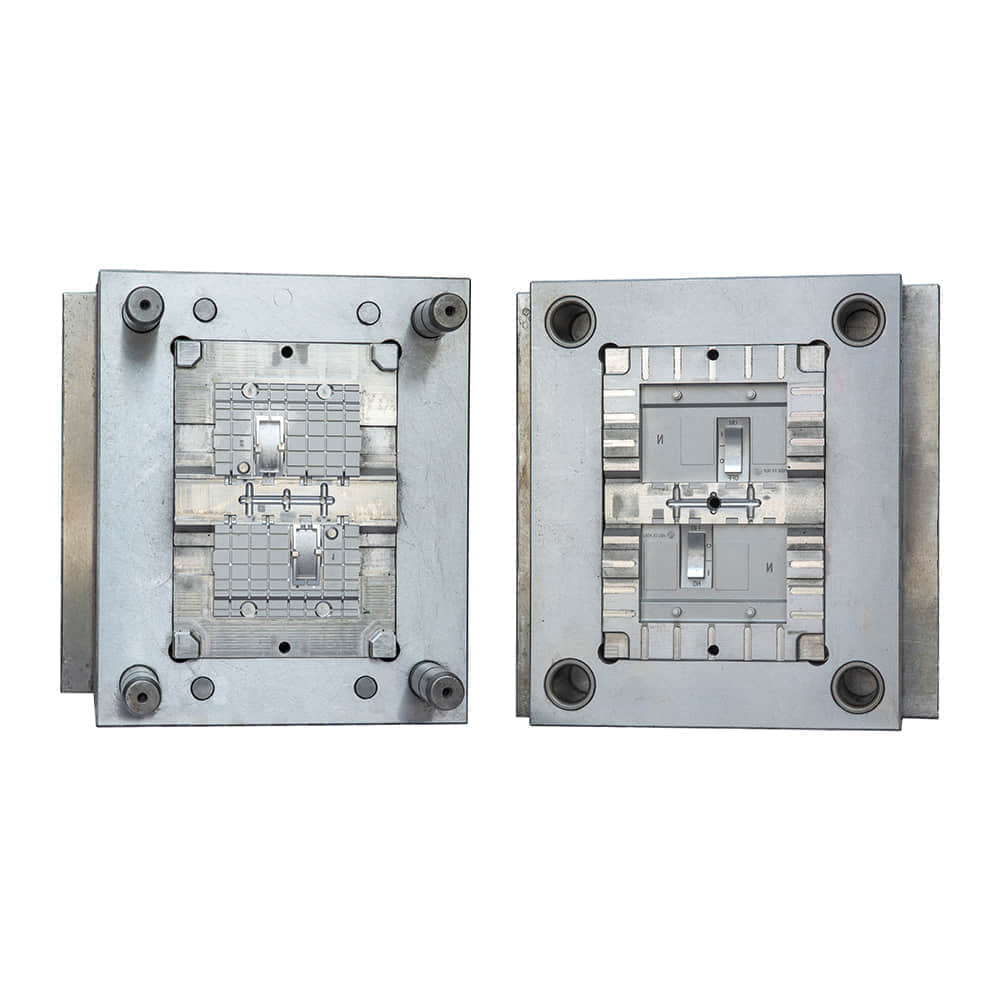

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity. This molten material cools and solidifies, taking on the shape of the mold, which is then ejected to create a finished product. It’s a versatile and efficient method used across various industries to produce everything from medical devices to automotive parts. The Role of Injection Mold Manufacturers Injection mold manufacturers are the architects of this process. They are responsible for creating the molds that dictate the final shape and quality of the product. The importance of their role cannot be overstated, as the mold’s precision and design directly impact the end product’s performance, cost, and appearance. Precision and Innovation Precision is the hallmark of a successful injection mold manufacturer. These professionals use cutting-edge technology and engineering expertise to craft molds with incredible precision, ensuring every product produced meets exact specifications. Innovation is another crucial aspect of their work. With the rapid advancements in materials science and manufacturing technology, mold manufacturers must stay at the forefront of their field. This includes experimenting with new materials, refining mold designs for enhanced efficiency, and incorporating automation for faster production. The Importance of Quality Control Quality control is paramount in injection molding. A slight imperfection in a mold can result in defects in every product it produces. This can be costly in terms of both time and resources. Injection mold manufacturers invest heavily in quality control processes, employing meticulous testing and inspection to guarantee that each mold meets rigorous standards before it’s put into production. Sustainability and Environmental Responsibility In today’s world, environmental responsibility is a critical consideration. Injection mold manufacturers are actively seeking ways to reduce the environmental impact of their processes. This includes exploring sustainable materials, optimizing production to minimize waste, and implementing energy-efficient technologies. Collaborative Partnerships Injection mold manufacturers don’t work in isolation. They collaborate closely with product designers, engineers, and manufacturers to ensure that the molds they create align with the broader vision of the final product. This collaborative approach fosters innovation and ensures that the end result meets or exceeds customer expectations. Meeting Diverse Industry Needs Injection mold manufacturers serve a wide array of industries. From aerospace to healthcare to consumer electronics, their molds are instrumental in producing components for an astonishing variety of products. This adaptability showcases the versatility of injection molding as a manufacturing method. Conclusion Injection mold manufacturers are the unsung heroes of modern manufacturing. Their precision, innovation, and commitment to quality underpin the production of countless products we use daily. As technology continues to advance and sustainability becomes increasingly important, these manufacturers will play an even more critical role in shaping the future of manufacturing. So, the next time you pick up your smartphone or use a plastic product, take a moment to appreciate the expertise and dedication of injection mold manufacturers, whose work remains largely hidden but is undeniably transformative.