Metal stamping is a vital industrial process that shapes and forms metal sheets into various components used in a multitude of products we encounter in our daily lives. From automotive parts to electronics, metal stamping plays a pivotal role in manufacturing. At the heart of this process are the unsung heroes known as metal stamping die manufacturers.

The Art and Science of Metal Stamping Die Manufacturing

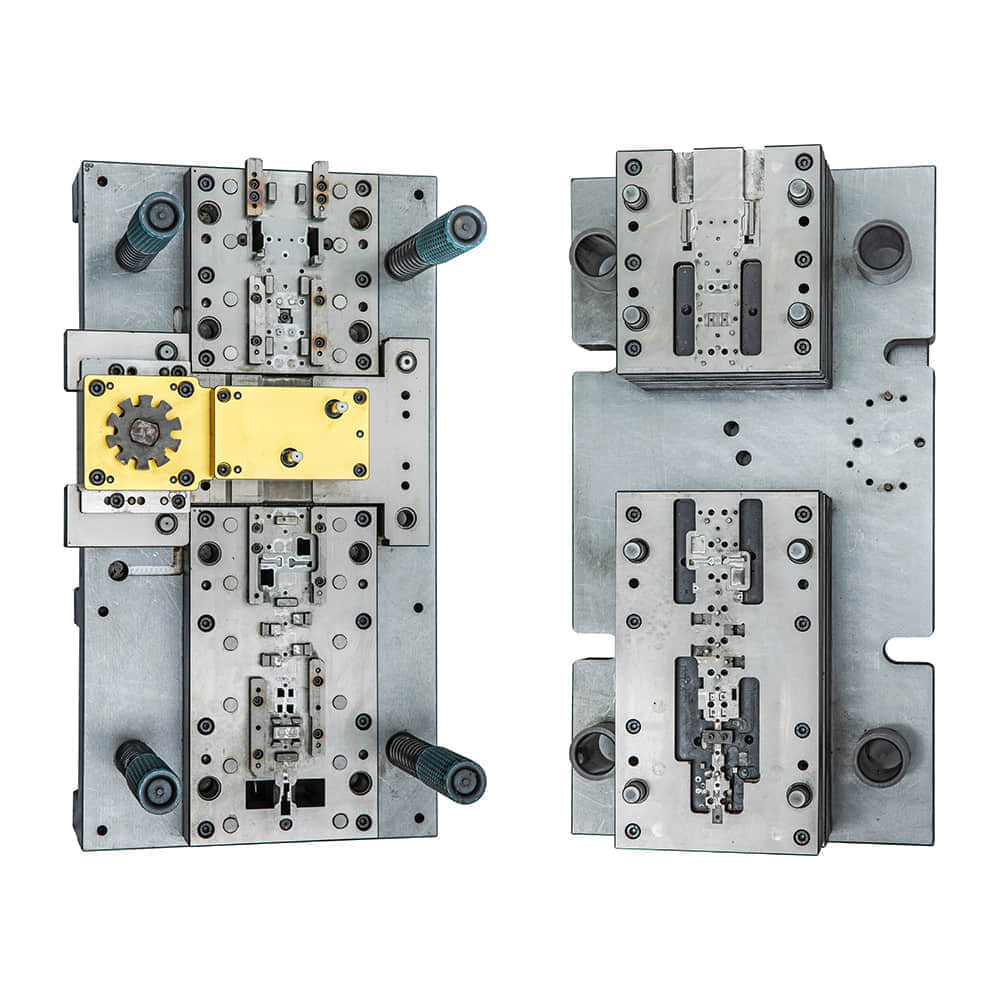

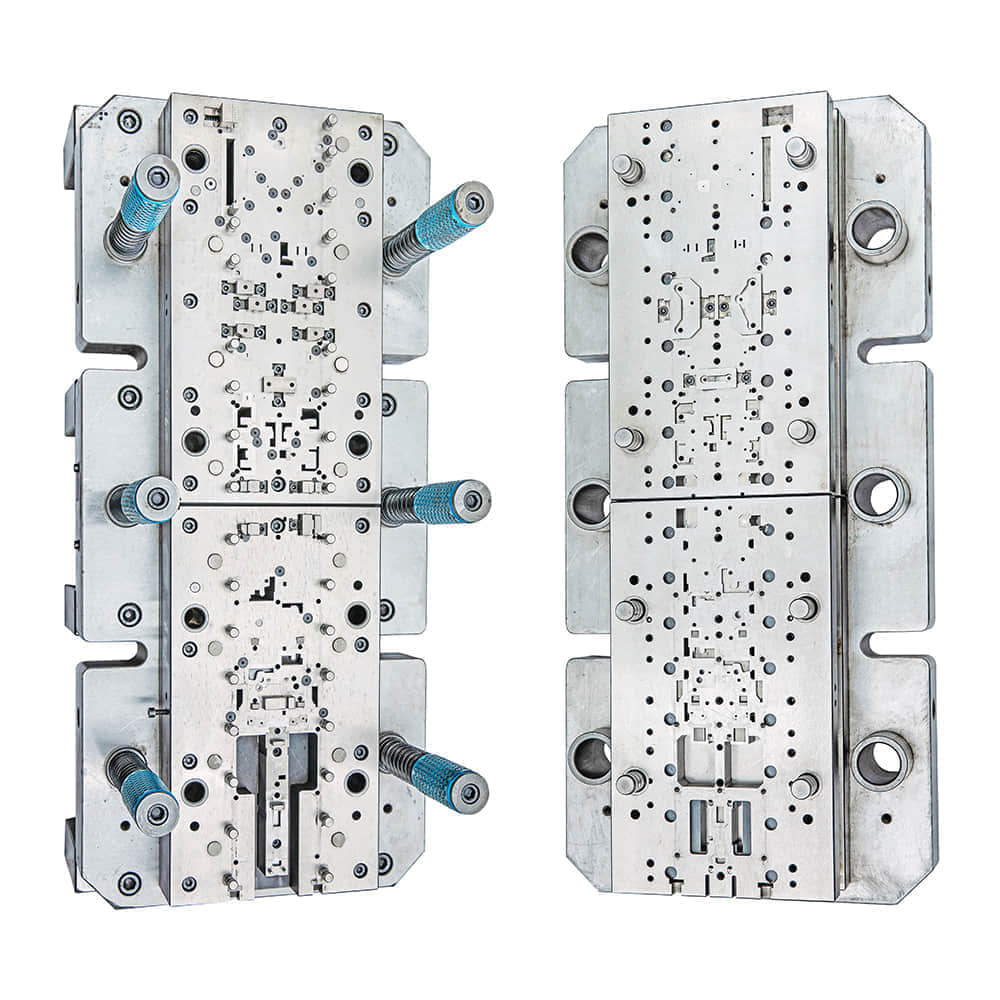

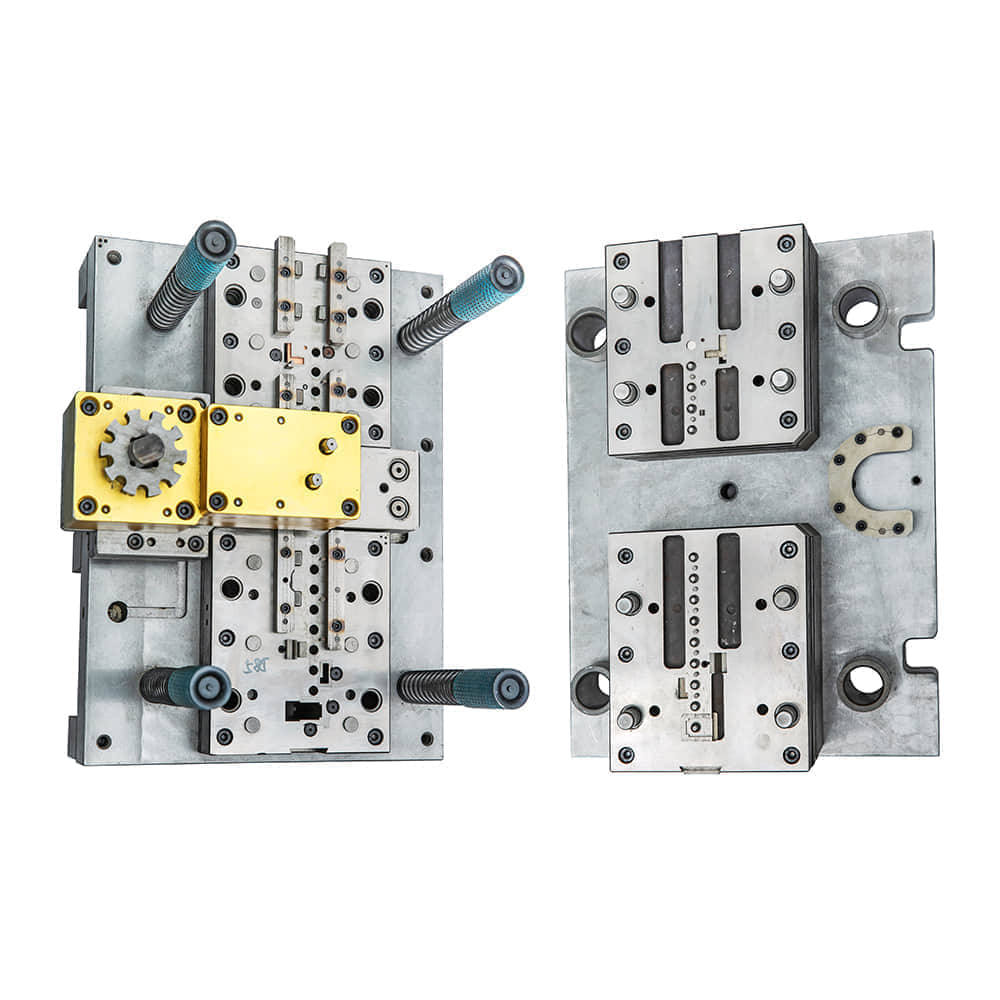

Metal stamping dies are tools that cut and shape metal sheets into desired forms. These dies are custom-crafted precision instruments, often made from high-quality tool steel, designed to withstand immense pressure and repeated use. They are the unsung heroes behind the scenes, ensuring that every stamped metal component meets the strictest quality and precision standards. The Role of Metal Stamping Die Manufacturers Metal stamping die manufacturers are the masterminds behind the scenes, creating the molds that breathe life into metal sheets. They are highly skilled engineers and craftsmen who possess a deep understanding of metallurgy, machining, and tool design. Their role is multifaceted and crucial in the manufacturing industry: 1. Design and Engineering: Metal stamping die manufacturers begin by collaborating closely with their clients, often automotive, aerospace, electronics, or appliance manufacturers, to understand the specific requirements of the stamped parts. This initial phase involves meticulous design and engineering, taking into account factors such as material type, sheet thickness, and the intricacies of the final product. 2. Precision Manufacturing: Once the design is finalized, metal stamping die manufacturers employ cutting-edge CNC machining and toolmaking techniques to craft the dies with unparalleled precision. The accuracy of these dies is paramount, as any deviations can lead to defective components and costly production delays. 3. Quality Assurance: Metal stamping die manufacturers rigorously test their creations to ensure they meet the highest quality standards. This includes conducting prototype runs, inspecting the stamped parts for defects, and making any necessary adjustments to the dies. Quality control is an ongoing process throughout the life of the die. 4. Continuous Improvement: Innovation is the lifeblood of the metal stamping die manufacturing industry. Manufacturers constantly strive to improve their processes and techniques, seeking ways to enhance precision, reduce production costs, and increase the lifespan of the dies. This commitment to innovation benefits not only the manufacturers but also the industries they serve. The Impact on Industries The work of metal stamping die manufacturers ripples throughout various industries. For example: Automotive Industry: In the automotive industry, metal stamping dies are used to create essential components like body panels, chassis parts, and engine components. The precision of these dies directly affects vehicle safety, performance, and aesthetics. Electronics Industry: In the electronics industry, metal stamping is crucial for creating precise and reliable connectors, heat sinks, and other components that power our electronic devices. The accuracy of the dies ensures seamless functionality and durability. Aerospace Industry: Aerospace manufacturers rely on metal stamping dies to produce lightweight and durable parts for aircraft and spacecraft. The stringent quality standards set by metal stamping die manufacturers are vital to ensure the safety of passengers and crew. Appliance Industry: In the appliance industry, metal stamping dies are used to craft components for refrigerators, washing machines, and other household appliances. The durability and precision of these dies contribute to the longevity and efficiency of these appliances. Conclusion Metal stamping die manufacturers are the hidden architects of the modern industrial world. Their expertise and commitment to precision play a pivotal role in ensuring that the products we rely on daily meet the highest quality standards. As technology continues to evolve, so too will the art and science of metal stamping die manufacturing, pushing the boundaries of what is possible in the world of precision engineering.