In the world of manufacturing, precision and efficiency are paramount. Industries ranging from automotive to electronics rely on the intricate art of metal stamping to produce components that power our everyday lives. Behind this crucial process lies the unsung hero – the Metal Stamping Die OEM Manufacturer. In this article, we delve into the world of these manufacturers and explore the critical role they play in shaping our modern world.

Introduction

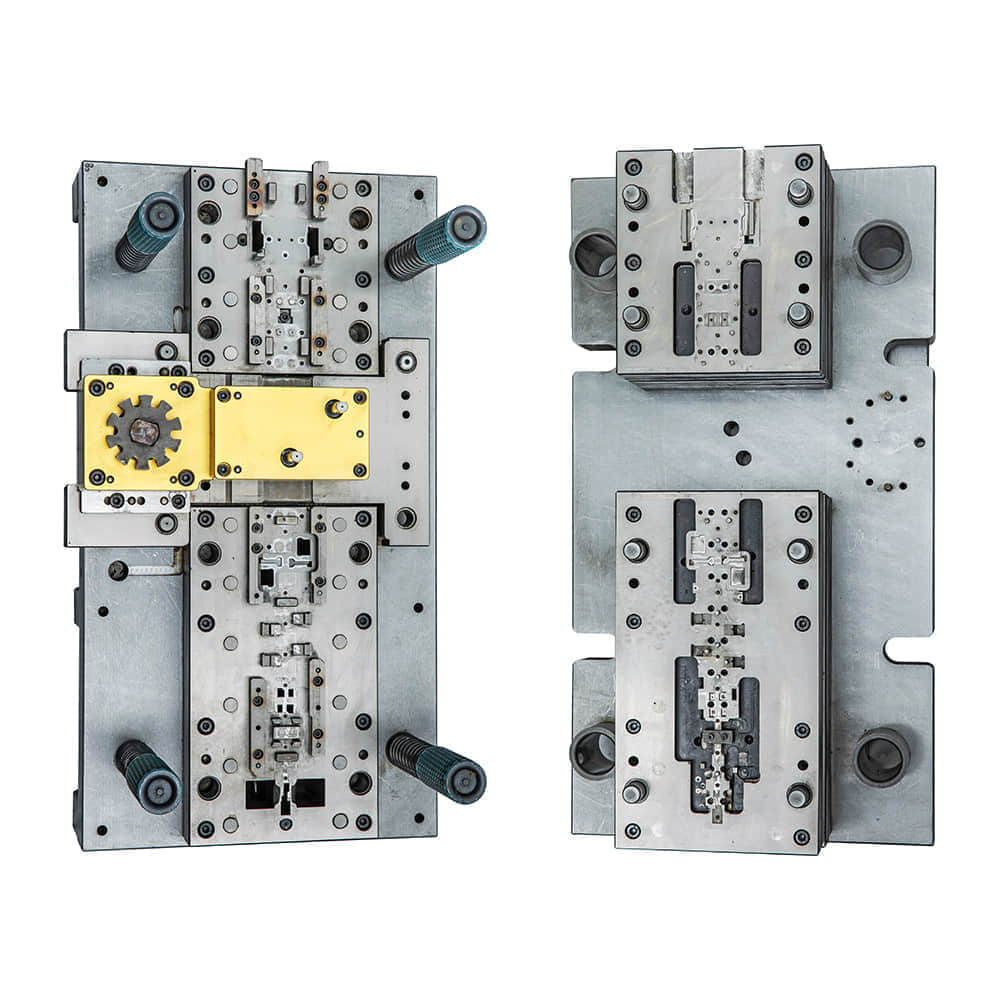

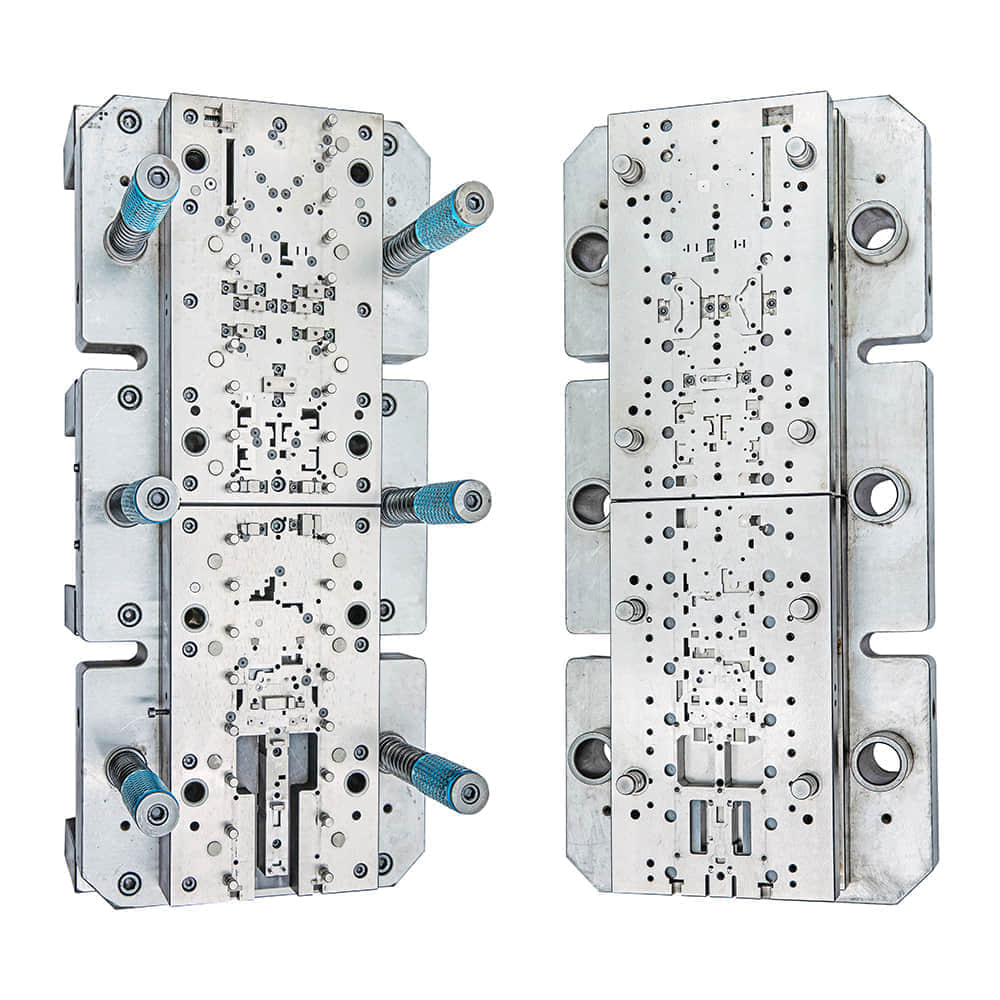

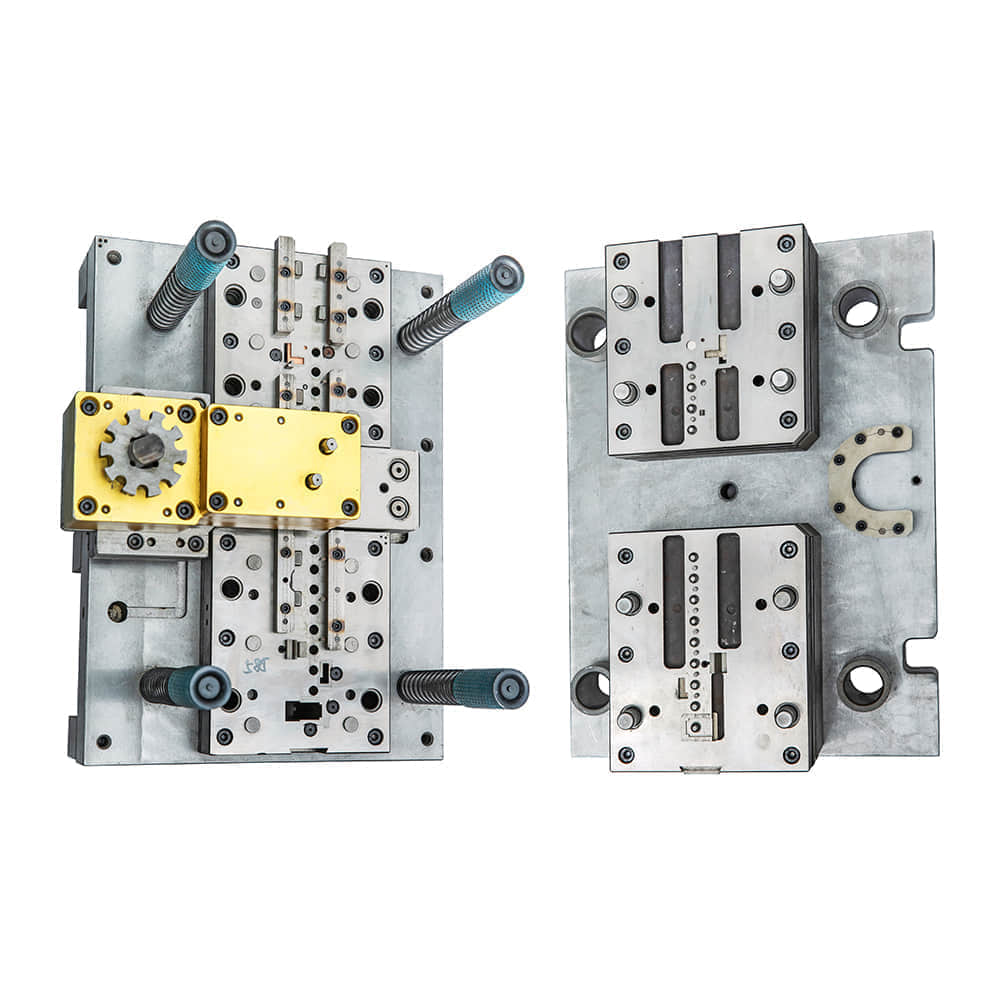

Metal stamping, a technique that involves cutting, bending, and shaping metal sheets to create parts and components, is at the core of countless manufacturing processes. Whether it’s the body panels of a car, the intricate parts of a smartphone, or the components of household appliances, metal stamping is the linchpin of modern production. The Precision Artisans Metal Stamping Die OEM Manufacturers are the precision artisans behind the scenes. They design, engineer, and craft the dies that transform raw metal sheets into perfectly shaped components. These manufacturers are the unsung heroes of the manufacturing industry, as their expertise is essential for maintaining quality and efficiency in production lines. Design and Engineering The journey begins with the design and engineering of stamping dies. Each component, regardless of its size or complexity, requires a unique die design. These designs factor in material properties, tolerances, and production volume. The Metal Stamping Die OEM Manufacturer must strike a balance between precision and durability, ensuring the dies withstand thousands or even millions of stamping cycles. Material Selection Choosing the right materials for stamping dies is a critical decision. High-strength tool steels are often the preferred choice due to their resilience and ability to maintain shape over time. Manufacturers must consider factors like heat resistance, wear resistance, and ease of machining to select the ideal material for each specific die. Precision Machining Once the die design is finalized and materials are selected, precision machining comes into play. Advanced CNC machines and EDM (Electrical Discharge Machining) technology are utilized to create the intricate shapes and patterns required for stamping. These machines are operated by skilled technicians who ensure that every detail is precisely replicated from the design. Quality Control Quality control is non-negotiable in the world of Metal Stamping Die OEM Manufacturing. Before a die is sent to the client, it undergoes rigorous testing and inspection. This includes dimensional accuracy checks, surface finish assessments, and simulated stamping trials to verify its performance under real-world conditions. Customization and Innovation The versatility of metal stamping means that each project can be highly customized. Metal Stamping Die OEM Manufacturers often collaborate closely with their clients to develop tailored solutions that meet specific production needs. Continuous innovation is key, as they strive to create dies that enable faster production, reduce waste, and improve overall product quality. Meeting Industry Demands As industries evolve, so do the demands on Metal Stamping Die OEM Manufacturers. The automotive industry, for instance, requires dies capable of handling advanced materials like high-strength aluminum alloys for lightweighting. Electronics manufacturers demand ever-smaller and more intricate components. These manufacturers must stay at the forefront of technology and technique to meet these evolving needs. Conclusion In the world of manufacturing, Metal Stamping Die OEM Manufacturers are the unsung heroes who enable the production of countless products that shape our daily lives. Their expertise in design, engineering, precision machining, and quality control ensures that the components we rely on are made with unparalleled accuracy and efficiency. As technology advances and industries continue to grow, Metal Stamping Die OEM Manufacturers will remain at the forefront of innovation, driving the future of manufacturing excellence.