Metal Stamping Die Manufacturers: Shaping the Future with Precision and Innovation

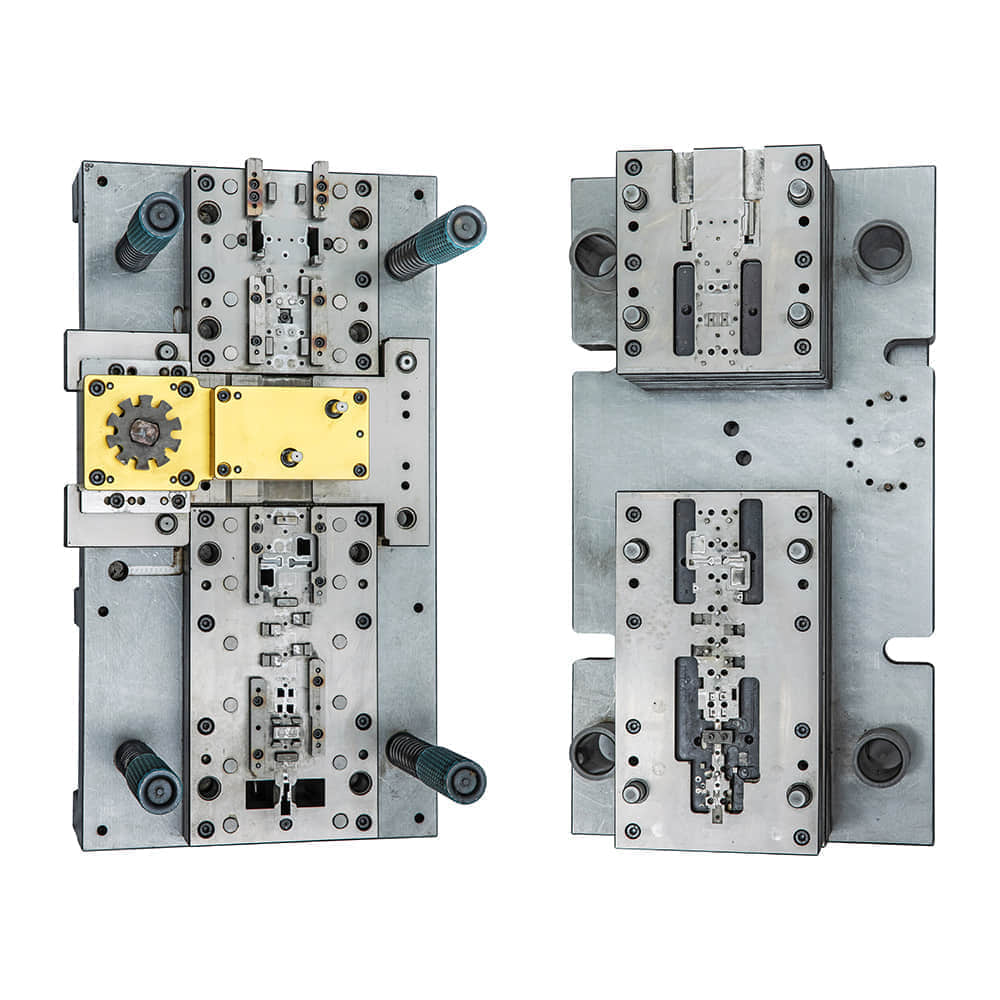

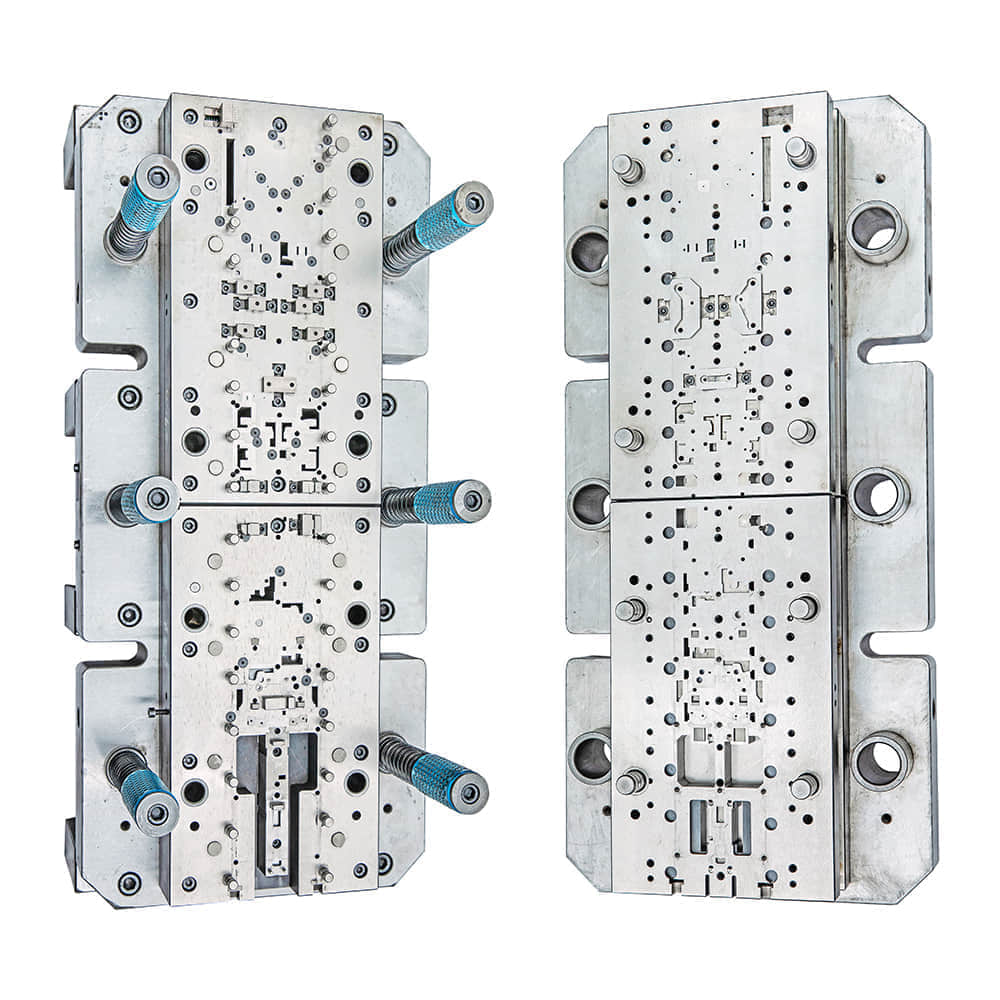

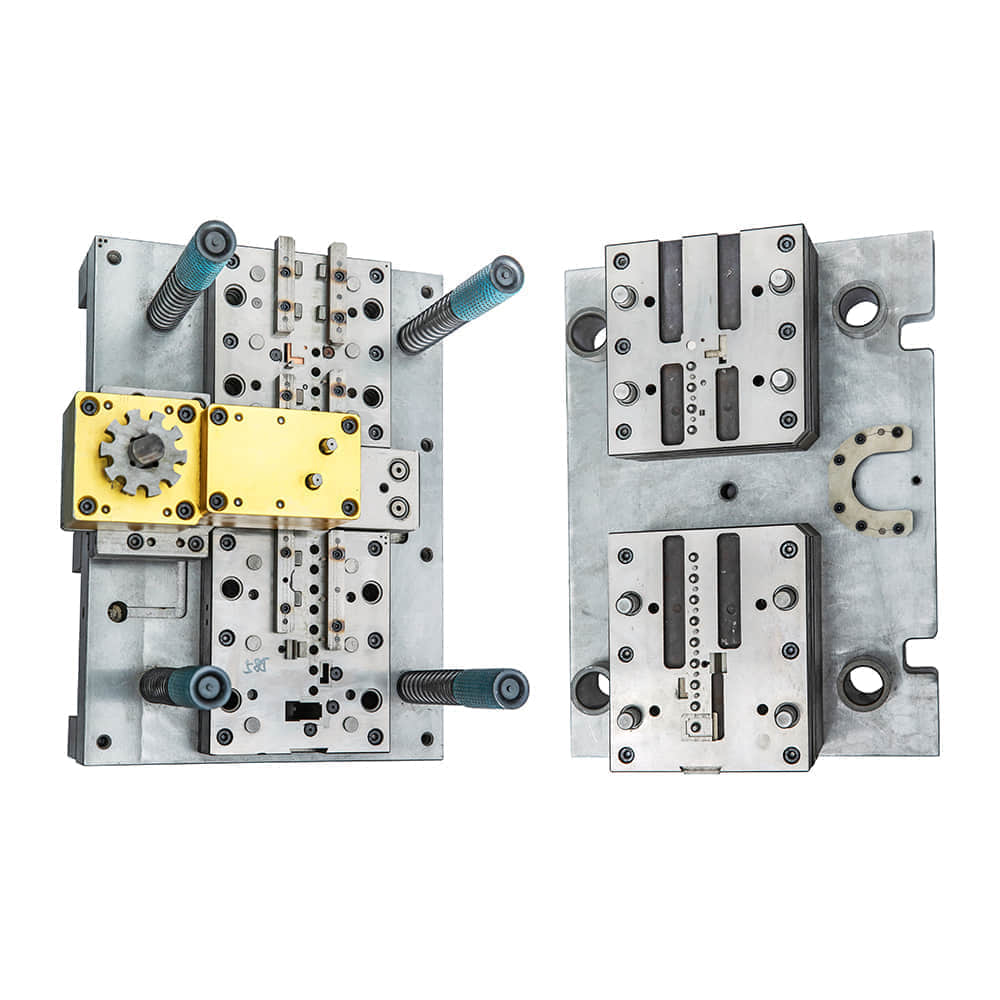

In the realm of modern manufacturing, metal stamping die manufacturers play a pivotal role in shaping the way countless products are crafted. These unsung heroes of the manufacturing industry create the intricate tools that enable the mass production of everything from simple metal components to complex automotive parts. Let’s delve into the world of metal stamping die manufacturers and explore the precision and innovation that define their work.

The Art of Precision Engineering Metal stamping die manufacturers are essentially master craftsmen of precision engineering. They design and fabricate the dies required to stamp, cut, or shape metal sheets into specific forms. The precision demanded by these dies is nothing short of extraordinary, often measured in micrometers. A slight miscalculation can lead to defective parts or compromised product integrity, highlighting the critical role of precision in this field. These professionals use cutting-edge software tools to design dies with unparalleled accuracy. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software assist in creating intricate blueprints, enabling manufacturers to visualize the final product before even starting the physical fabrication process. This level of meticulous planning reduces errors and allows for efficient adjustments before production begins. Innovation at Its Core Innovation is the beating heart of the metal stamping die manufacturing industry. With each new product design and material innovation, manufacturers face fresh challenges. They must adapt to these changes by developing new techniques and technologies that align with evolving industry standards. One area of innovation is the integration of smart manufacturing technologies. Internet of Things (IoT) sensors embedded within dies and stamping equipment allow for real-time monitoring of production processes. This ensures higher quality control, minimizes downtime, and enables predictive maintenance. Furthermore, manufacturers are exploring advanced materials for die production. High-strength alloys and coatings enhance durability and longevity, reducing the need for frequent die replacements. This not only saves costs but also contributes to a more sustainable manufacturing process. Collaboration and Customization Collaboration between manufacturers and their clients is a cornerstone of success in this industry. Metal stamping die manufacturers work closely with product designers and engineers to understand the exact specifications required. This collaboration ensures that the final product meets the desired standards and performance criteria. Customization is another key aspect of their work. Every product demands a unique approach, and manufacturers pride themselves on their ability to tailor solutions to fit specific needs. Whether it’s a simple metal bracket or a complex automotive body panel, metal stamping die manufacturers are equipped to design and produce the necessary tooling. Challenges and Future Outlook While metal stamping die manufacturing has made remarkable strides, it’s not without its challenges. The industry must continually adapt to fluctuating material costs, changing regulations, and increasing demands for shorter production cycles. Moreover, as industries shift toward electrification and lightweight materials, manufacturers must develop dies that accommodate these changes. Looking ahead, the future of metal stamping die manufacturing seems promising. Advancements in automation, artificial intelligence, and materials science are poised to revolutionize the field. As products become more intricate and materials more diverse, manufacturers will continue to push the boundaries of what’s possible. Conclusion Metal stamping die manufacturers are the unsung heroes behind the scenes, contributing significantly to the products that shape our daily lives. Their dedication to precision, innovation, collaboration, and customization is the foundation of modern manufacturing. As technology advances and industries evolve, these manufacturers will undoubtedly remain at the forefront of progress, driving the production of high-quality products with unparalleled precision.