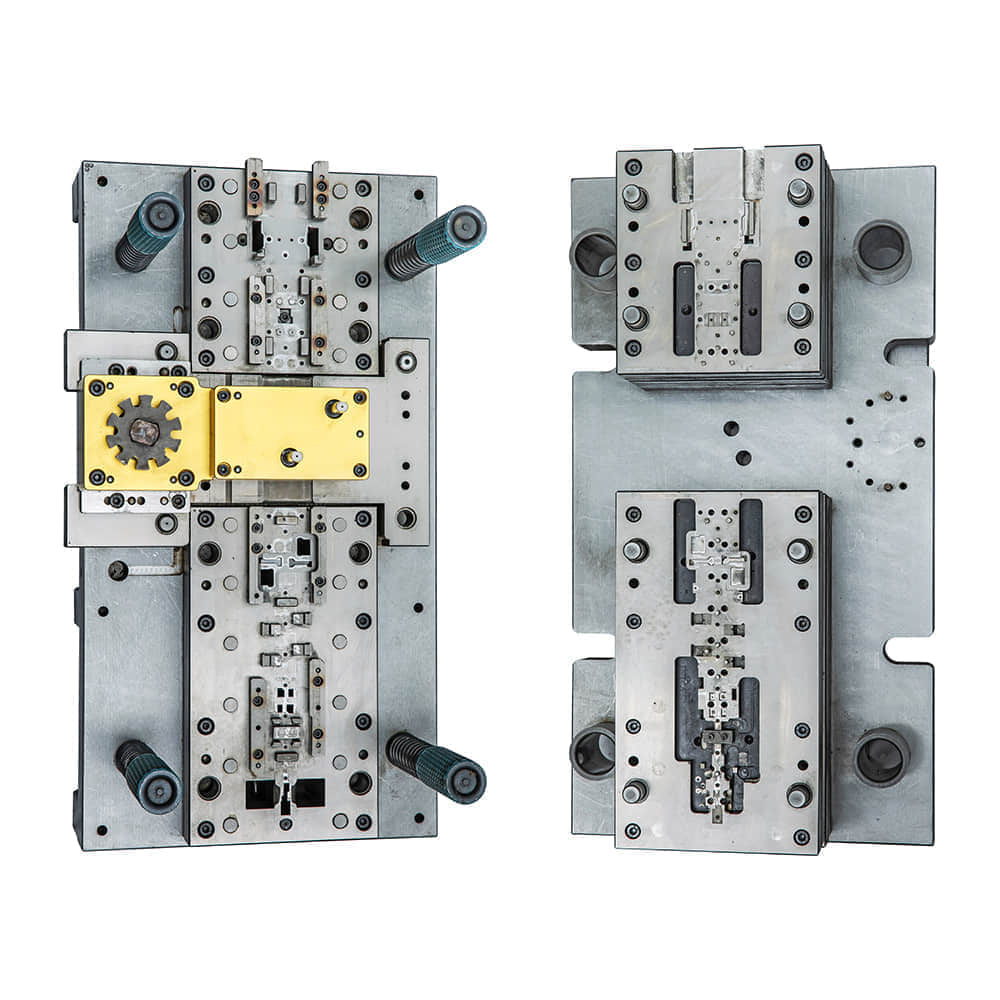

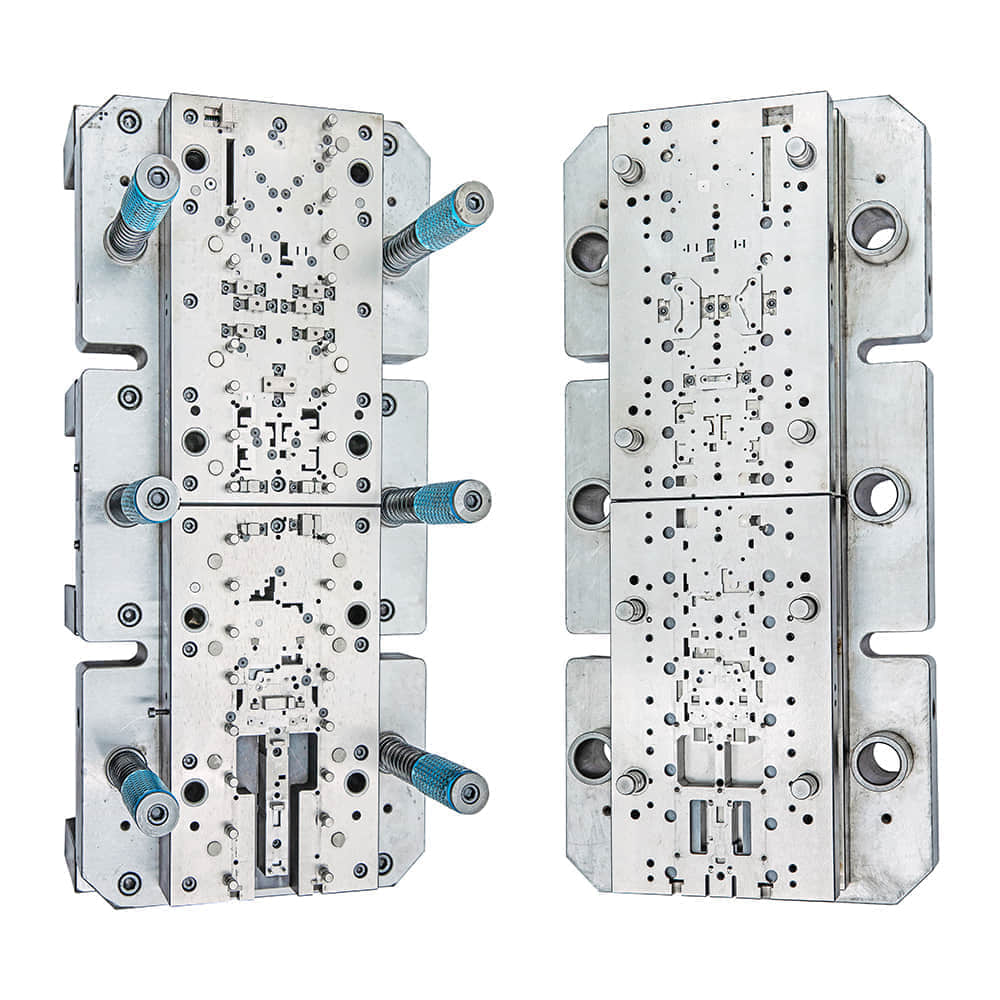

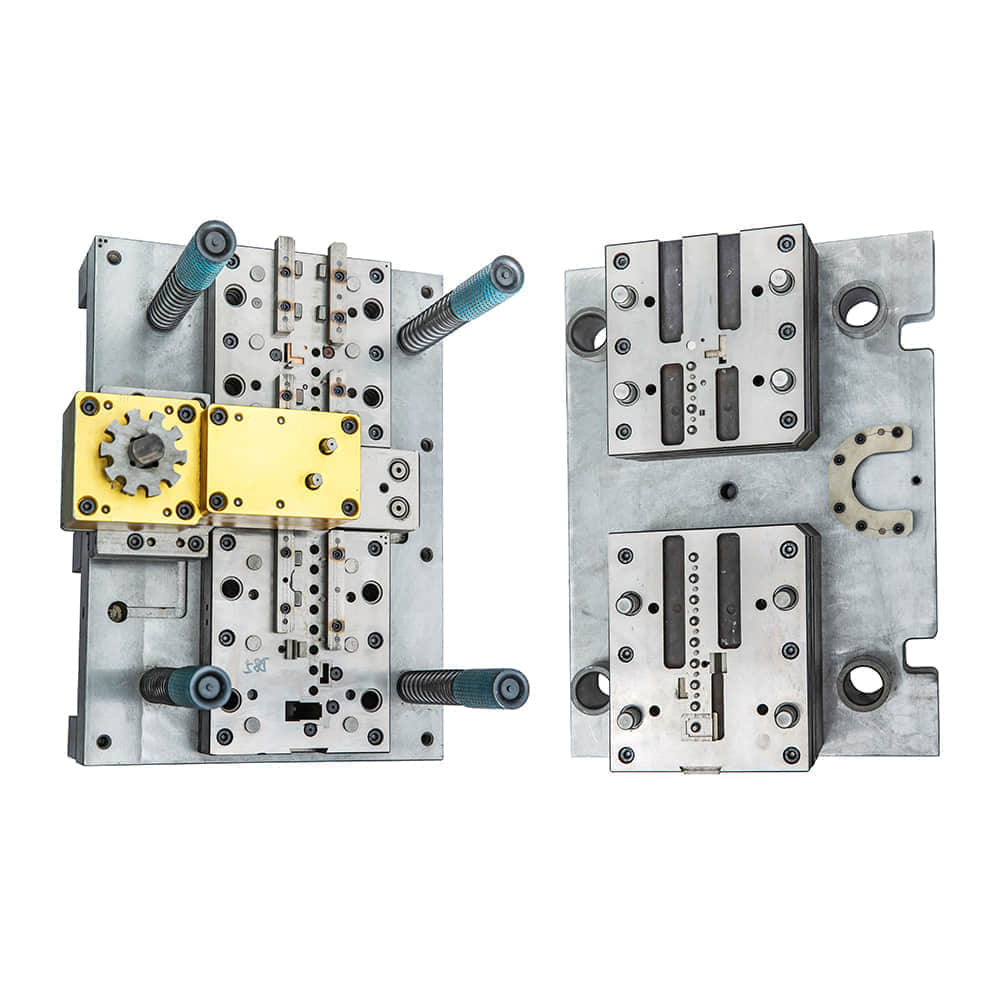

Metal stamping die manufacturing is a vital industry that plays a pivotal role in shaping various sectors such as automotive, aerospace, electronics, and more. This intricate and essential process involves the creation of precision tools used to shape, cut, or form metal sheets or components with accuracy and consistency. In this article, we will delve into the fascinating world of metal stamping die manufacturers, exploring their significance, the intricacies of their craft, and the innovations that drive this industry forward.

The Significance of Metal Stamping Die Manufacturers

Metal stamping dies are at the core of countless manufacturing processes, serving as the foundation for the mass production of parts and components used in various products. From car body panels to intricate electronic components, metal stamping dies enable the efficient and cost-effective production of essential items that we rely on in our daily lives. Craftsmanship and Precision Creating a metal stamping die is a meticulous and highly skilled endeavor. Manufacturers start with detailed blueprints and designs that specify the exact dimensions and specifications required for the end product. This includes considerations for materials, tolerances, and desired surface finishes. The craftsmanship begins with the selection of high-quality tool steel or carbide, which can withstand the extreme pressures and abrasion involved in the stamping process. Skilled machinists then use state-of-the-art computer numerical control (CNC) machines and specialized software to meticulously shape the die components with sub-micron precision. These components, including punches and dies, must be crafted to the highest standards to ensure consistency and durability during mass production. The assembly of the die is another critical step in the process. Each component must fit together seamlessly to ensure uniformity in the stamped parts. This requires the expertise of experienced tool and die makers who meticulously assemble, test, and fine-tune the dies until they meet the exact specifications of the design. Innovations Driving the Industry The field of metal stamping die manufacturing is constantly evolving, driven by innovations that enhance precision, efficiency, and sustainability. Some of the key advancements in this industry include: Computer-Aided Design (CAD):CAD software allows designers to create intricate die designs with unparalleled precision. This technology enables manufacturers to simulate and optimize stamping processes before physical production begins, reducing errors and waste. High-Speed Machining:Advances in CNC machining have significantly increased the speed and accuracy of die component fabrication. High-speed machining not only reduces production time but also enhances the quality of the final product. Materials Innovation:The development of new materials, such as advanced tool steels and coatings, has improved the longevity and performance of metal stamping dies, reducing the need for frequent replacements and maintenance. Automation and Robotics:Automation and robotics have streamlined the manufacturing process, from die component fabrication to quality control. These technologies increase efficiency and reduce labor costs while maintaining consistent quality. Environmentally-Friendly Practices:Metal stamping die manufacturers are increasingly adopting sustainable practices, such as recycling materials and minimizing waste, to reduce their environmental footprint. Conclusion The world of metal stamping die manufacturing is a fascinating blend of craftsmanship and cutting-edge technology. These precision tools are the unsung heroes behind the mass production of countless everyday items. As innovations continue to shape this industry, we can expect even greater precision, efficiency, and sustainability in the manufacturing processes that drive our modern world. Metal stamping die manufacturers play a vital role in shaping the future of manufacturing, ensuring that quality and precision remain at the forefront of industry standards.