In the realm of manufacturing, precision and innovation are the cornerstones that drive progress. One industry that epitomizes these qualities is metal stamping die production. As the demand for intricate metal components grows across diverse sectors, the role of Original Design Manufacturer (ODM) manufacturers becomes increasingly vital. In this article, we delve into the world of metal stamping die ODM manufacturers, exploring their significance, processes, and impact on various industries.

A Glimpse into Metal Stamping Die ODM Manufacturing

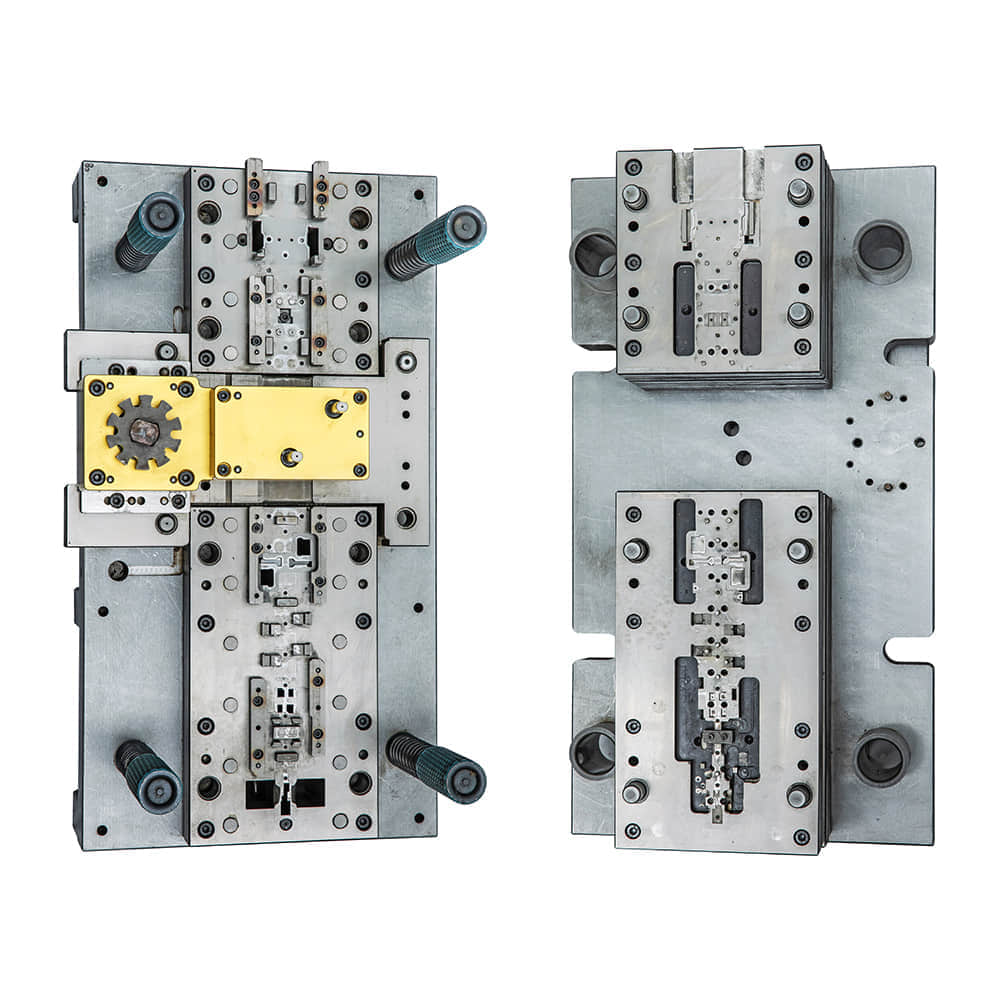

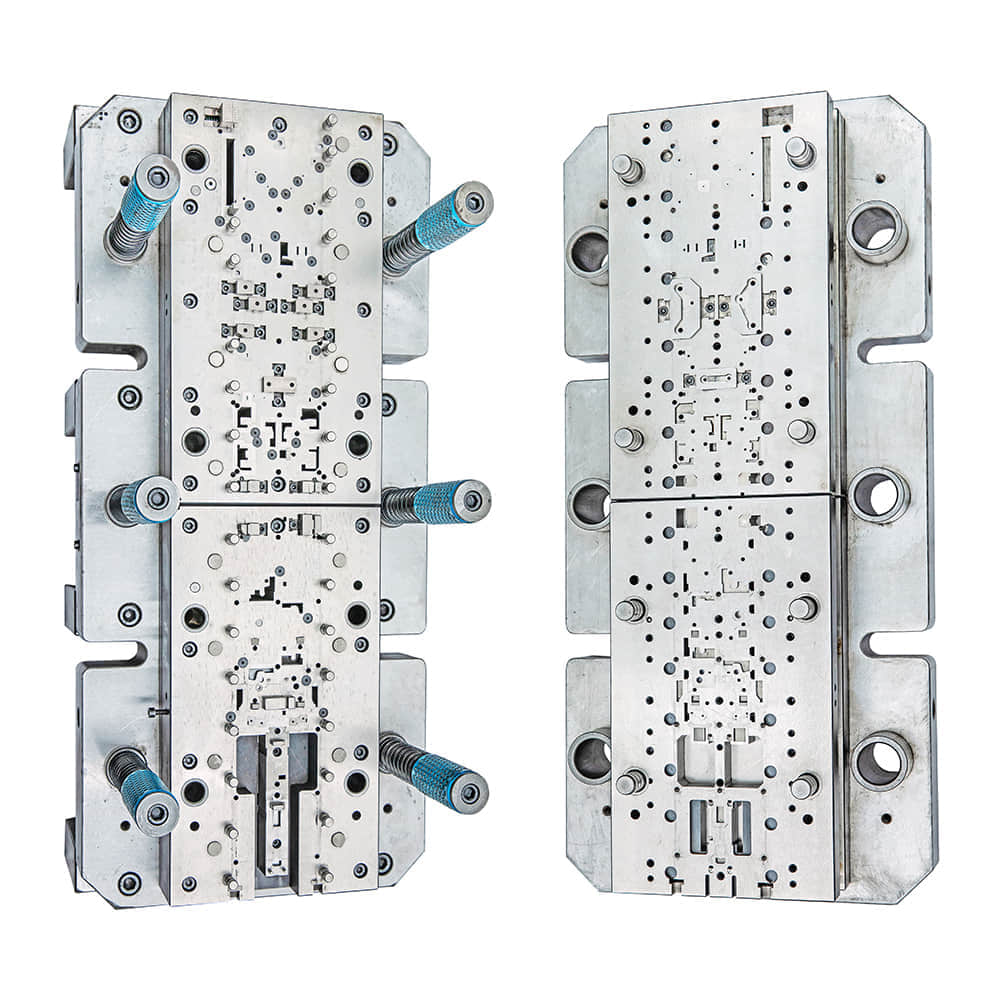

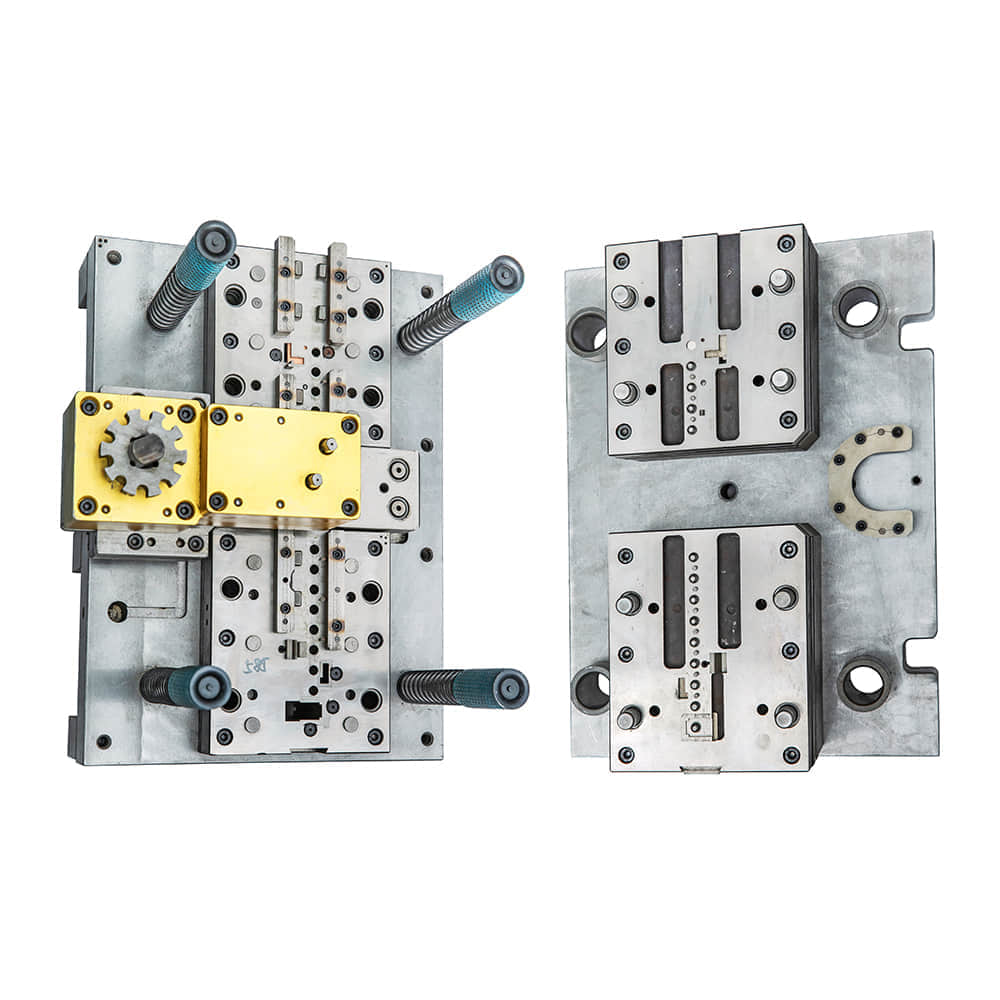

Metal stamping die ODM manufacturers play an integral role in producing high-precision metal components used in a multitude of products, ranging from automobiles to consumer electronics. Unlike Original Equipment Manufacturer (OEM) manufacturers who produce based on predefined specifications, ODM manufacturers are known for their innovation and flexibility in designing and fabricating metal stamping dies. This approach enables them to create tailored solutions that cater to diverse client needs. The Essence of Precision Precision is the heartbeat of metal stamping die ODM manufacturing. These manufacturers utilize cutting-edge technologies, such as computer-aided design (CAD) software and advanced machining equipment, to craft dies with unparalleled accuracy. The intricate patterns, cavities, and reliefs etched into these dies determine the final shape and dimensions of the stamped metal components. Even a minor deviation can lead to defective parts or compromised product performance. Innovative Design at the Core Innovation is a driving force behind ODM manufacturing. Metal stamping die ODM manufacturers invest in research and development to pioneer new techniques and materials, elevating the quality and efficiency of the manufacturing process. This constant pursuit of innovation allows them to stay ahead in an ever-evolving landscape and offer clients solutions that are both groundbreaking and functional. Shaping Diverse Industries The impact of metal stamping die ODM manufacturers resonates across a diverse range of industries. Automotive manufacturers rely on these precision-crafted components for engine parts, chassis, and intricate electronic systems. In the electronics sector, metal stamping dies are pivotal in producing components for smartphones, laptops, and home appliances. Even the medical field benefits from their expertise, as these manufacturers contribute to producing medical devices with exacting specifications. The Collaborative Approach Collaboration stands as a fundamental pillar of metal stamping die ODM manufacturing. These manufacturers work closely with their clients to understand their unique requirements and challenges. This collaborative approach ensures that the final product aligns seamlessly with the client’s vision and needs. Moreover, by fostering an open line of communication, ODM manufacturers can offer insights and suggestions that further enhance the design and functionality of the stamped components. Sustainability and Efficiency In recent years, sustainability has become a paramount concern across industries. Metal stamping die ODM manufacturers are no exception. By employing efficient manufacturing processes, optimizing material usage, and minimizing waste, these manufacturers contribute to a greener and more sustainable manufacturing ecosystem. Additionally, the longevity and durability of the components they produce contribute to the overall lifecycle sustainability of the end products. Conclusion In the dynamic world of manufacturing, metal stamping die ODM manufacturers stand out as pioneers of precision and innovation. Their expertise spans industries, crafting components that form the backbone of modern technology and products. With a commitment to collaboration and sustainability, these manufacturers continue to shape the future of manufacturing, one precisely stamped component at a time.