Metal stamping parts have emerged as a cornerstone of modern manufacturing, facilitating the production of intricate components that power countless industries. This article delves into the realm of metal stamping, exploring its processes, applications, and significance in today’s world.

Precision in Every Punch: The Basics of Metal Stamping

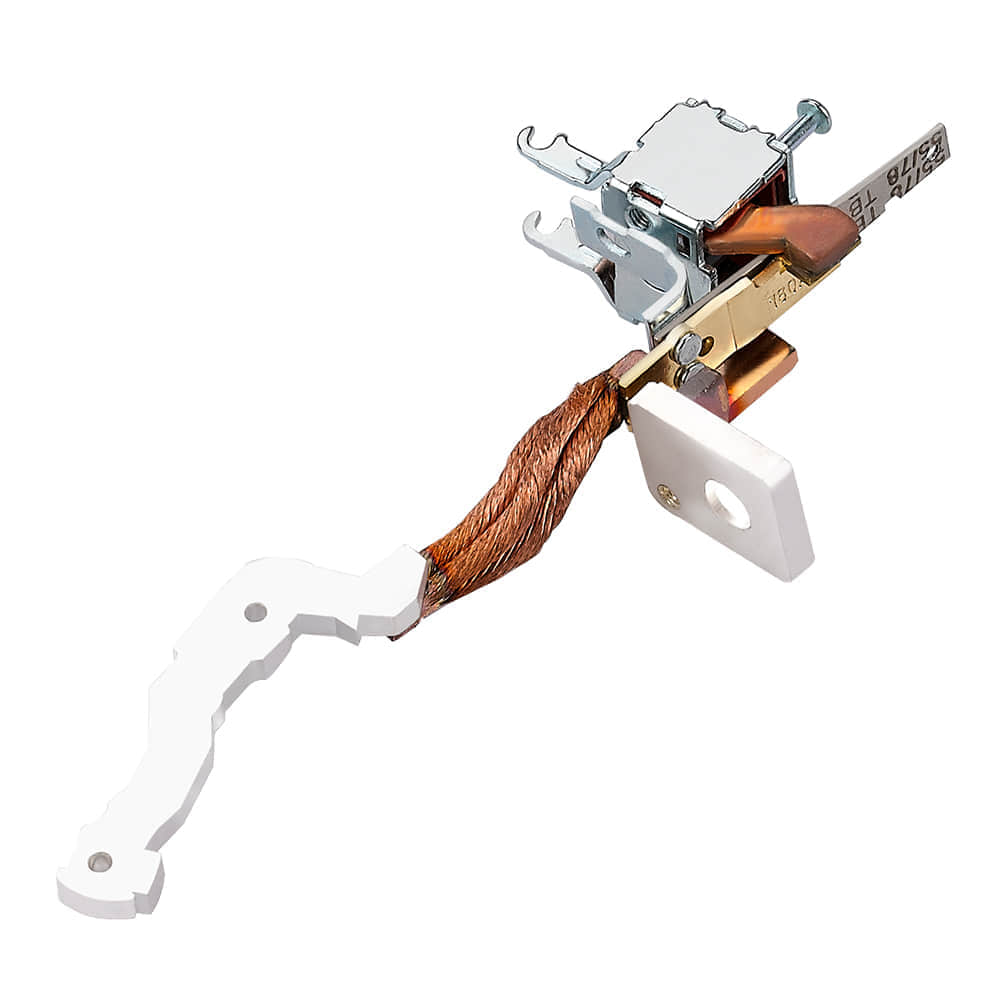

Metal stamping is a manufacturing process that involves shaping flat metal sheets into various forms through the use of dies and presses. The process relies on the forceful application of pressure to cut, form, or reshape the metal. One of the key advantages of metal stamping is its precision; intricate designs and complex shapes can be achieved consistently, ensuring the creation of uniform and reliable parts. The Stamping Process: Steps to Perfection The metal stamping process consists of several essential steps, each contributing to the final product’s accuracy and quality. First, the design is converted into a die, which is a specialized tool used for cutting and forming the metal. The metal sheet is then positioned within the press, which exerts force on the die, causing the metal to take its desired shape. Depending on the complexity of the part, multiple stamping operations may be required to achieve the final form. Applications Across Industries: Where Metal Stamping Shines The versatility of metal stamping parts makes them a valuable asset across numerous industries. In the automotive sector, metal stamping produces components ranging from engine parts to intricate interior elements. Electronics benefit from metal stamping for the creation of connectors and housings, ensuring precise fits and shielding. The aerospace industry relies on stamped parts for their lightweight yet robust characteristics, contributing to fuel efficiency and safety. Even everyday items, such as kitchen appliances and consumer electronics, owe their functionality to the precision of metal stamping. Advantages Galore: Why Metal Stamping Matters Metal stamping offers a plethora of advantages that contribute to its significance in manufacturing: Cost Efficiency:Mass production capabilities and minimal material waste make metal stamping a cost-effective choice for large-scale production. Consistency:The use of automated processes ensures uniformity in the production of parts, reducing the risk of defects. Complexity:Metal stamping allows for the creation of intricate designs and shapes that might be challenging to achieve through other methods. Speed:High-speed stamping presses can rapidly produce large quantities of parts in a short amount of time. Material Compatibility:Metal stamping can be applied to a wide range of metals, from steel and aluminum to copper and brass. Quality Control and Beyond: Ensuring Excellence Maintaining quality is paramount in metal stamping. Rigorous testing and inspection procedures are implemented to ensure that the produced parts meet the required specifications. Computerized systems and advanced metrology tools play a pivotal role in assessing dimensional accuracy and identifying any deviations. Conclusion: Shaping a Precise Future Metal stamping parts stand as a testament to human innovation and engineering prowess. Their precision, versatility, and efficiency have revolutionized industries, from automotive to electronics, aerospace to everyday appliances. As technology continues to advance, metal stamping is poised to reach new heights, enabling the creation of increasingly intricate and reliable components that power our modern world.