In the dynamic landscape of modern manufacturing, metal stamping has emerged as a pivotal process, driving industries forward through its precision and innovation. At the heart of this evolution lie metal stamping parts manufacturers, the unsung heroes of many products we encounter daily. This article delves into the world of these manufacturers, exploring their significance, processes, and impact on various sectors.

The Crucial Role of Metal Stamping Parts Manufacturers

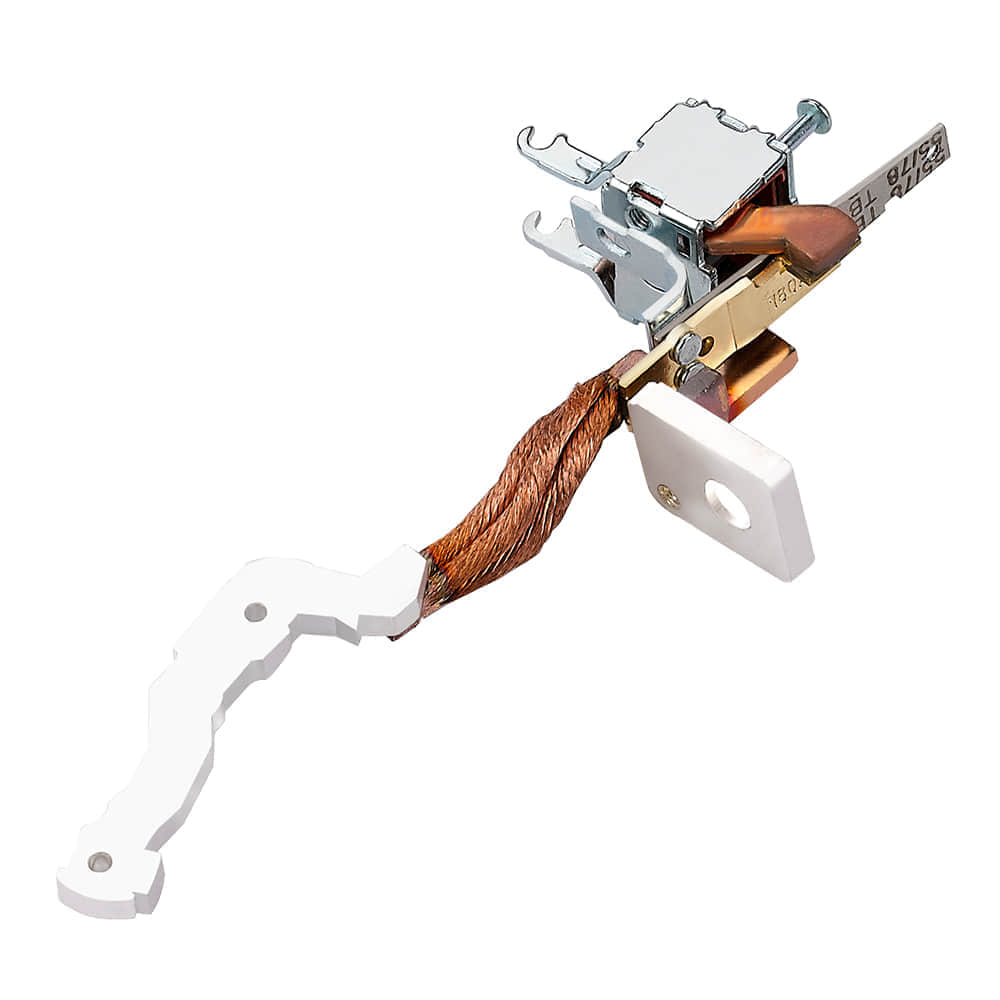

Metal stamping parts manufacturers play a crucial role in producing components that are fundamental to numerous industries, ranging from automotive and aerospace to electronics and consumer goods. Their expertise lies in transforming flat metal sheets into intricate shapes, creating parts that exhibit precision, consistency, and durability. These components serve as building blocks, contributing to the overall functionality and performance of end products. Precision through Advanced Technology Central to the success of metal stamping is the integration of advanced technology. Computer-aided design (CAD) software is used to meticulously plan the design and dimensions of each part before production even begins. This digital precision ensures that every component adheres to the exact specifications required by the client. The actual stamping process often involves the use of high-tonnage presses, which exert immense force to shape the metal. With the aid of progressive dies and tooling, manufacturers can create even the most intricate geometries with exceptional accuracy. Innovation Driving Efficiency Innovation is a driving force within the realm of metal stamping. Manufacturers are constantly seeking new ways to enhance their processes, whether it’s through material selection, tooling advancements, or automation integration. The push for lighter, stronger, and more sustainable materials has led to the exploration of alloys and composites that not only meet but exceed industry standards. Additionally, automation has revolutionized metal stamping, optimizing production speed while maintaining consistent quality. Robotic arms, precision sensors, and machine learning algorithms work harmoniously to ensure that each stamped part is free from defects. Adapting to Industry-Specific Needs One of the remarkable aspects of metal stamping parts manufacturers is their ability to adapt to the unique needs of various industries. The automotive sector, for instance, requires components that can withstand extreme conditions while providing optimal safety. Aerospace demands parts that are not only lightweight but also able to endure the stresses of high-altitude travel. In the realm of electronics, precision is paramount, with components needing to fit together flawlessly in compact devices. The versatility of metal stamping allows manufacturers to tailor their processes to meet these specific demands. Global Impact and Sustainability Metal stamping parts manufacturers have a global impact that extends beyond borders. As the backbone of diverse supply chains, they contribute to the creation of products that are distributed worldwide. However, with this global influence comes the responsibility to embrace sustainability. Manufacturers are increasingly adopting eco-friendly practices, such as recycling scrap metal and minimizing waste generation. By embracing sustainable materials and processes, the industry is working toward reducing its carbon footprint and creating a more environmentally conscious future. Conclusion The world of metal stamping parts manufacturers is a realm where precision and innovation converge to shape the future of manufacturing. Their contributions to various industries, driven by technology, adaptability, and sustainability, are truly commendable. As we continue to rely on the products they help create, let us recognize the dedication and expertise that these manufacturers bring to the table, elevating the quality and performance of items we encounter daily.