In the world of metal fabrication, metal stamping parts play a pivotal role in creating a diverse range of precision components for various industries. This process, often referred to as metal stamping or stamping, involves shaping metal sheets into desired forms using presses and dies. Let’s delve into the intricacies and benefits of metal stamping parts.

Precision Engineering

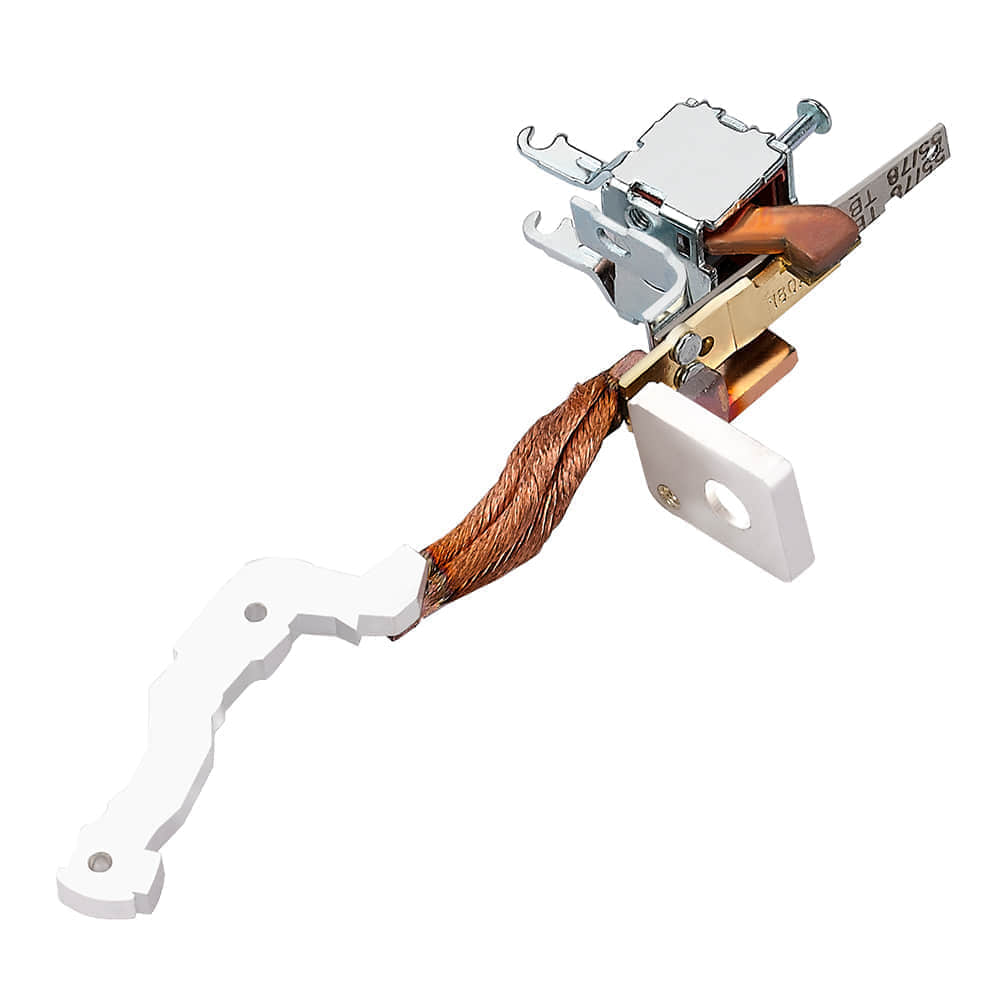

Metal stamping is a precision engineering process, where the metal sheets are pressed into shape under immense pressure within a die. This ensures high accuracy and consistency in the final product. The dies are carefully designed to produce specific shapes and sizes, allowing for intricate details and complex geometries. The precision achieved through stamping is unmatched, making it a popular choice for high-precision applications. Cost-Effectiveness Metal stamping is an economical process, especially for large-scale production. While the initial cost of dies and tooling can be significant, the cost per part decreases significantly as production volumes increase. This makes stamping an ideal choice for manufacturers looking to produce high volumes of identical or similar parts cost-effectively.