Blanking Dies: The Fundamental Components of Precision Manufacturing

Blanking dies are critical tools in the world of precision manufacturing. They play an essential role in the production of various metal and non-metal parts used in countless industries, from automotive to electronics. In this article, we will explore what blanking dies are, how they work, their applications, and the importance of their design and maintenance.

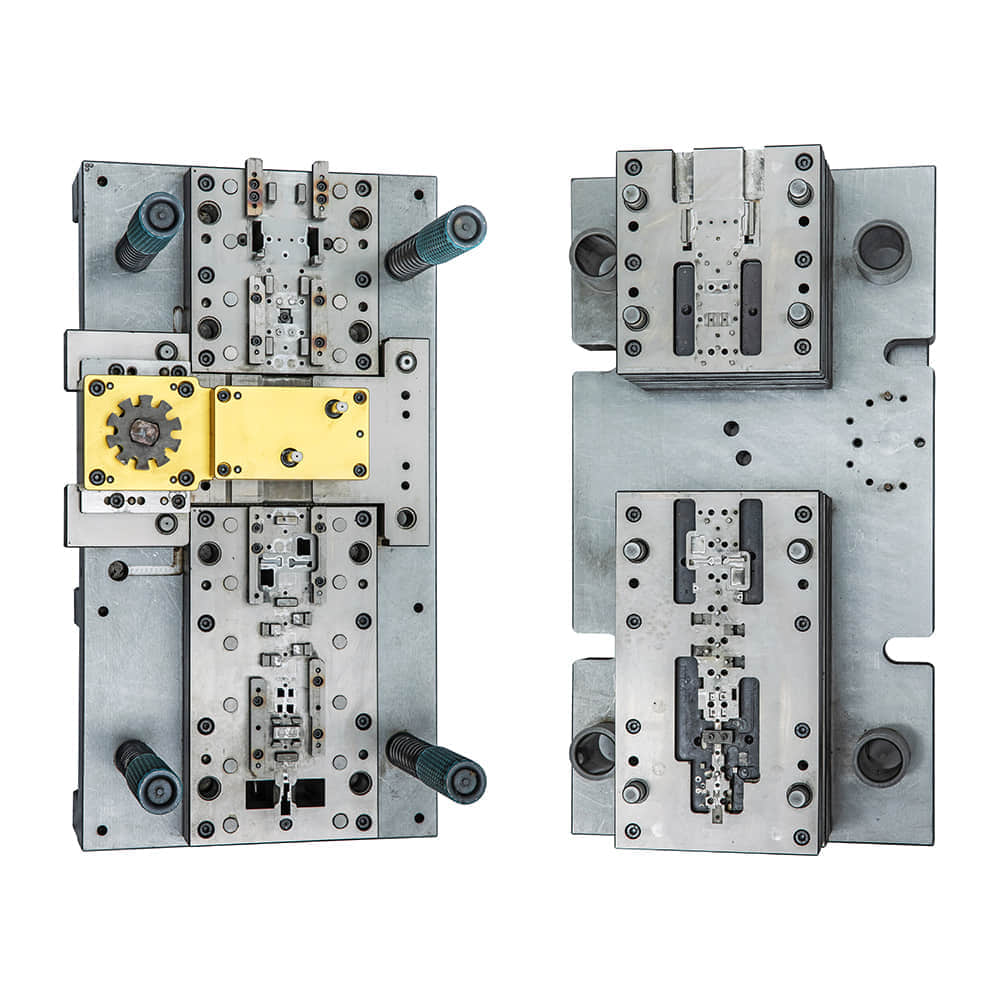

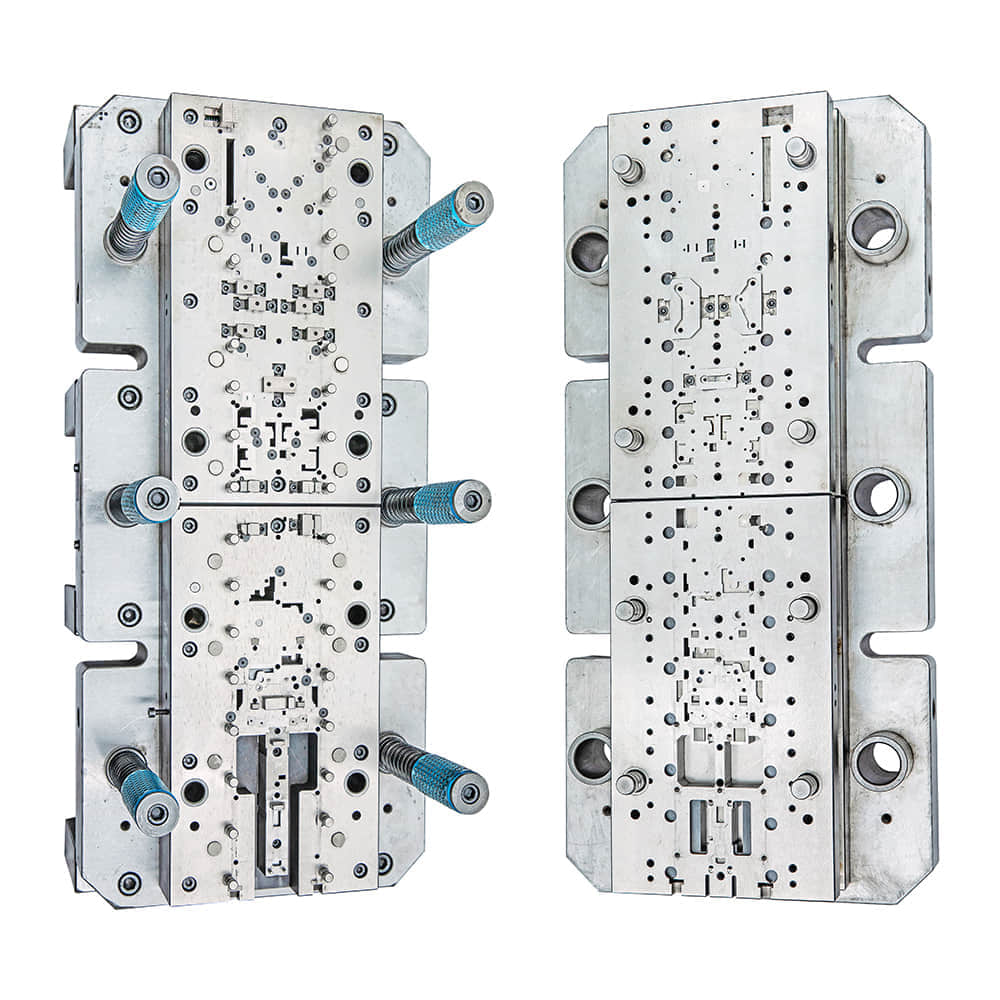

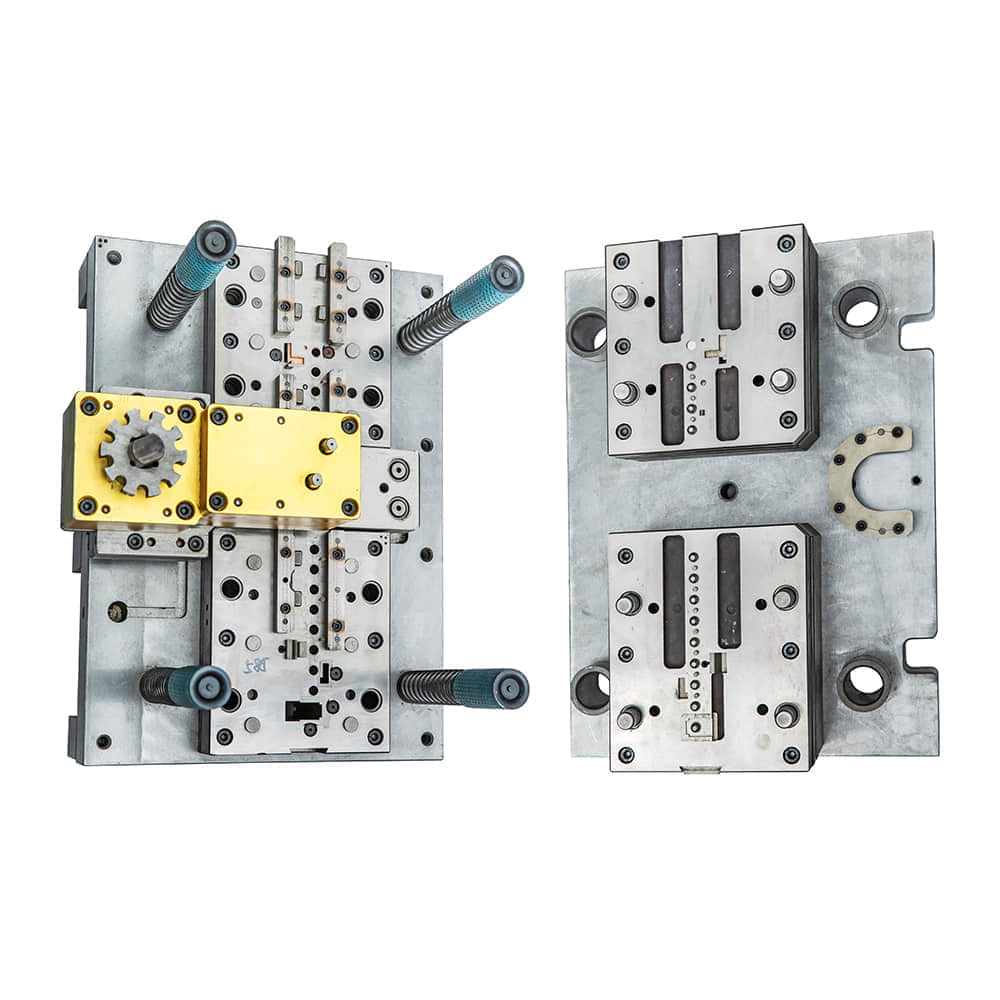

What Are Blanking Dies? Blanking dies are specialized cutting tools used to shear flat sheet or strip materials into various shapes and sizes with high precision. These materials can be metals like steel, aluminum, or non-metallic materials like plastics and rubber. The primary purpose of blanking is to create flat, intricate shapes that will later be further processed or assembled into finished products. How Do Blanking Dies Work? Blanking dies work on a simple but highly effective principle: they consist of two main parts—the punch and the die. The punch is the upper part, while the die is the lower part. When the material to be blanked is placed between them, the punch descends rapidly and cuts or punches the desired shape through the material. The die provides support and maintains the material’s integrity during the cutting process. Several factors influence the design of blanking dies, including the material to be cut, the desired shape, and the required precision. The die may have additional features such as guide pins, which help align the material accurately, and ejector pins, which assist in removing the cut parts from the die. Applications of Blanking Dies Blanking dies find applications in a wide range of industries, including: Automotive:Blanking dies are used to produce various automotive components, such as gears, brackets, and engine parts. Electronics:They are essential for manufacturing electronic components like connectors and terminals. Appliances:Many parts of household appliances, such as washing machines and refrigerators, are produced using blanking dies. Aerospace:Blanking dies are used to fabricate components for aircraft and spacecraft. Medical Devices:Precision parts for medical equipment are often created using blanking dies. Consumer Goods:Items like razors, cutlery, and even toys rely on blanking dies for their production. The Importance of Design and Maintenance The design of blanking dies is a critical factor in ensuring the quality and accuracy of the final product. Engineers must carefully consider factors such as material selection, die clearance, and punch and die hardness to achieve the desired results. Proper maintenance of blanking dies is equally crucial to extend their lifespan and maintain product quality. Regular inspections, sharpening, and lubrication are essential maintenance tasks. Conclusion In summary, blanking dies are indispensable tools in precision manufacturing, enabling the production of intricate shapes from sheet or strip materials. Their applications span across various industries, contributing to the creation of countless everyday products. The design and maintenance of blanking dies are pivotal in ensuring the efficiency and longevity of these essential tools. As technology advances, so too will the capabilities of blanking dies, allowing for even greater precision and efficiency in manufacturing processes.