Metal Stamping Die Manufacturers: Masters of Precision

In the intricate world of manufacturing, where precision and efficiency reign supreme, Metal Stamping Die Manufacturers emerge as the unsung heroes. These skilled artisans craft the tools that shape countless metal components used in a myriad of industries. This article delves into the artistry and innovation that defines Metal Stamping Die Manufacturers and their vital role in modern production.

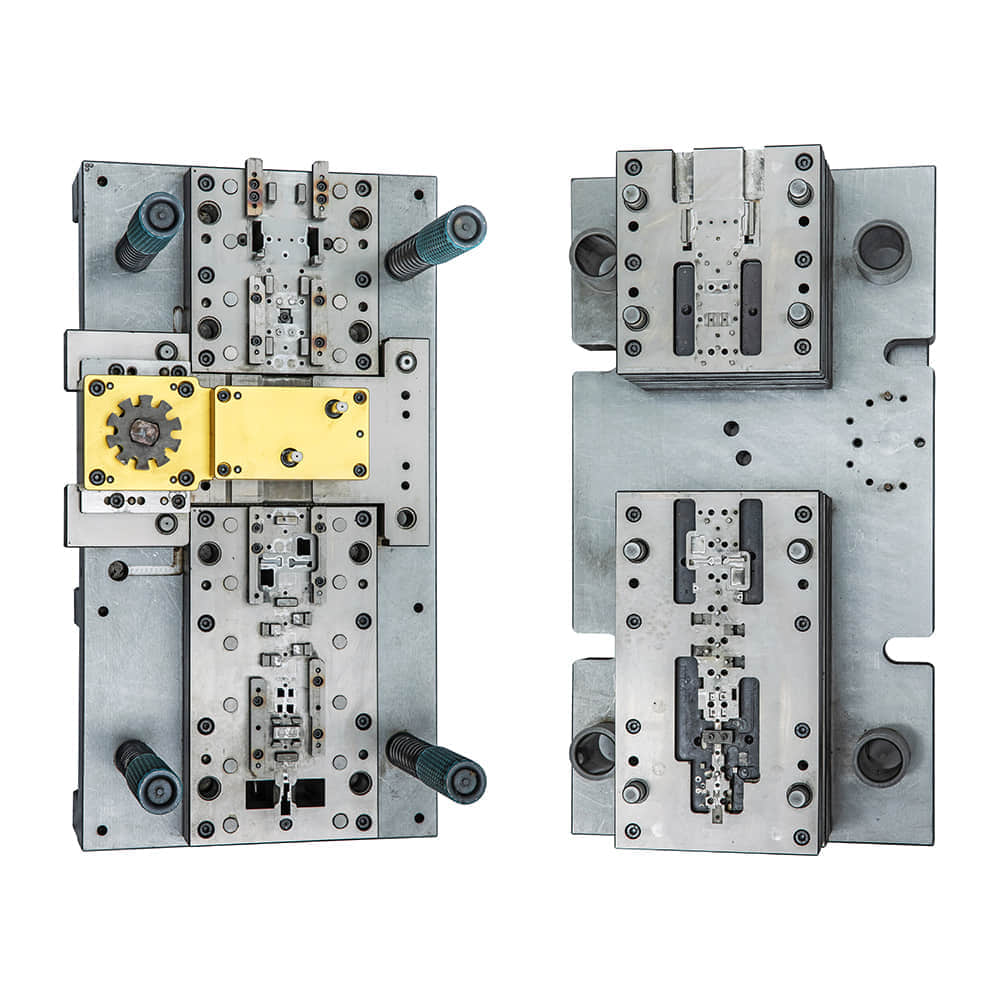

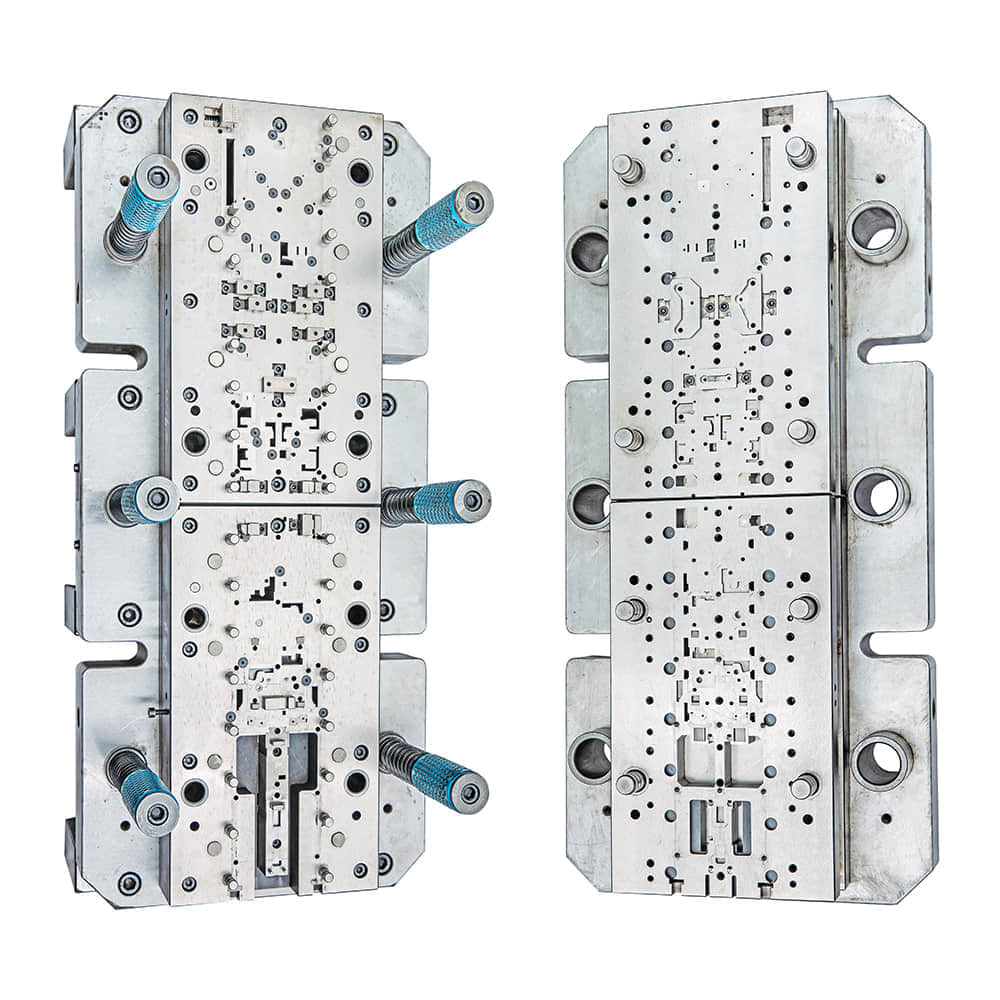

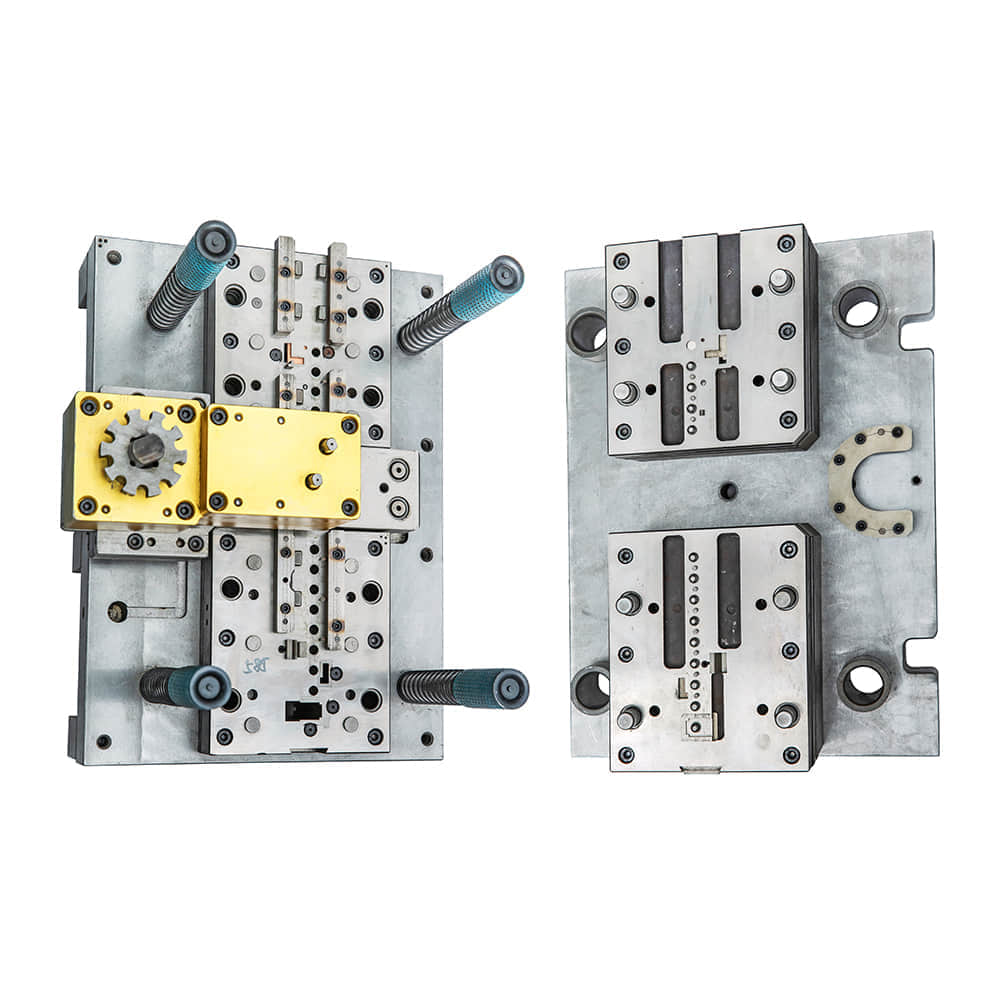

The Craftsmanship of Metal Stamping Die Manufacturing At its core, metal stamping is a process used to transform flat metal sheets into various shapes and sizes. This technique is an integral part of industries such as automotive, aerospace, electronics, and more. Behind every impeccably stamped part lies a meticulously crafted metal stamping die. The art of metal stamping die manufacturing begins with the selection of the right materials. Typically, tool steels are chosen for their exceptional hardness and durability, ensuring that the die can withstand the extreme pressures and repetitive stamping cycles. Each die is meticulously machined and heat-treated to achieve the perfect combination of hardness and toughness. Designing for Perfection Precision is the hallmark of metal stamping, and the design phase plays a pivotal role in achieving it. Metal Stamping Die Manufacturers employ advanced CAD (Computer-Aided Design) software to create intricate die designs with exacting tolerances. These designs factor in the material type, thickness, and desired end product, ensuring that every stamp results in a flawless component. Moreover, the dies must be designed for longevity, as they endure thousands, if not millions, of stamping cycles. This requires careful consideration of wear and tear, as well as regular maintenance plans to keep the dies in optimal condition. The Role of Innovation As technology advances, Metal Stamping Die Manufacturers are at the forefront of innovation. They constantly seek ways to enhance the precision and efficiency of their dies. One such innovation is the use of automated die change systems, which reduce downtime and increase overall productivity. Additionally, the integration of sensors and real-time monitoring systems allows manufacturers to track the performance of their dies, identifying issues before they lead to defects. This commitment to innovation ensures that metal stamping remains a cost-effective and reliable manufacturing method. Environmental Responsibility In an era of heightened environmental awareness, Metal Stamping Die Manufacturers are also taking steps to reduce their environmental footprint. Sustainable die manufacturing practices involve minimizing waste, optimizing energy consumption, and using eco-friendly materials whenever possible. These efforts not only benefit the planet but also contribute to cost savings in the long run. Meeting Industry-Specific Demands Different industries have unique requirements when it comes to metal stamping, and Metal Stamping Die Manufacturers must adapt to these demands. Whether it’s producing precision components for medical devices or crafting robust parts for the automotive sector, these artisans tailor their dies to meet industry-specific standards and regulations. Conclusion In the world of manufacturing, Metal Stamping Die Manufacturers are the artisans who craft the tools of precision. Their dedication to craftsmanship, innovative spirit, and commitment to environmental responsibility ensure that metal stamping remains a reliable and indispensable manufacturing method across various industries. As we continue to advance in technology and materials, the artistry of metal stamping die manufacturing will remain a critical element of modern production.