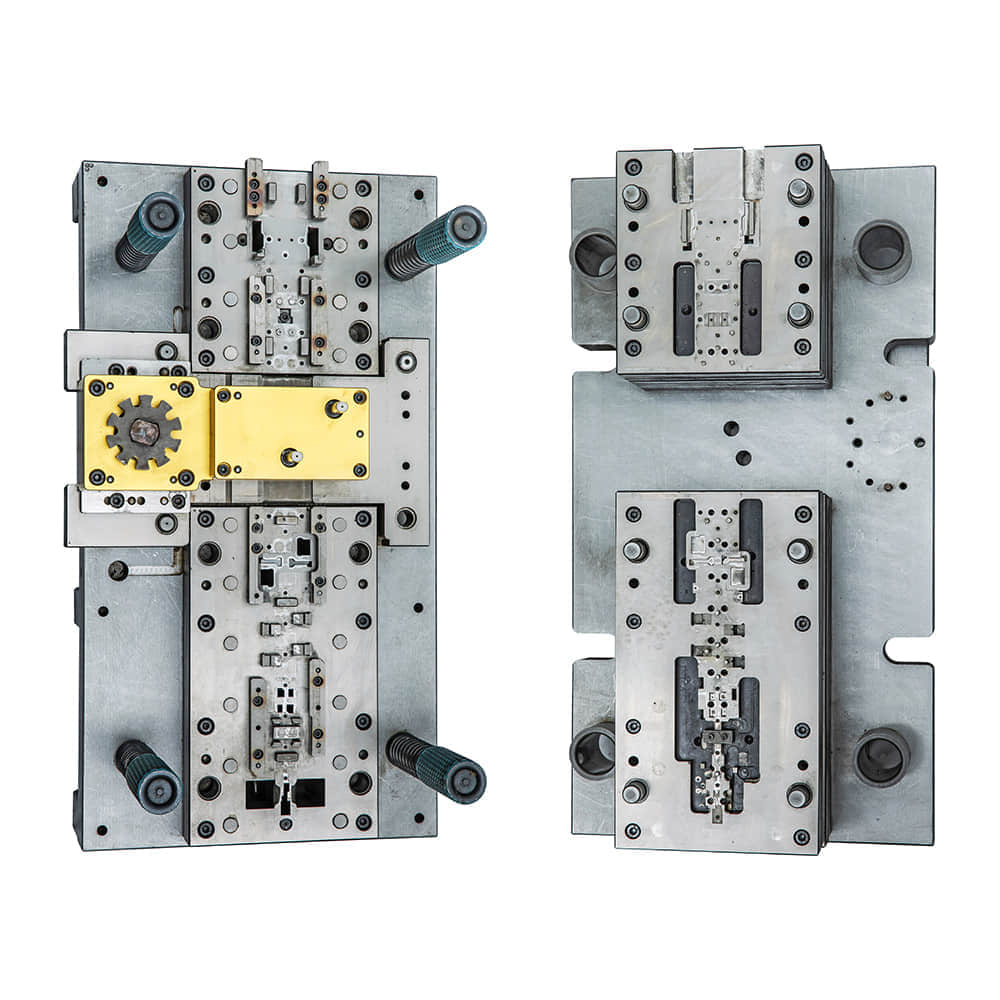

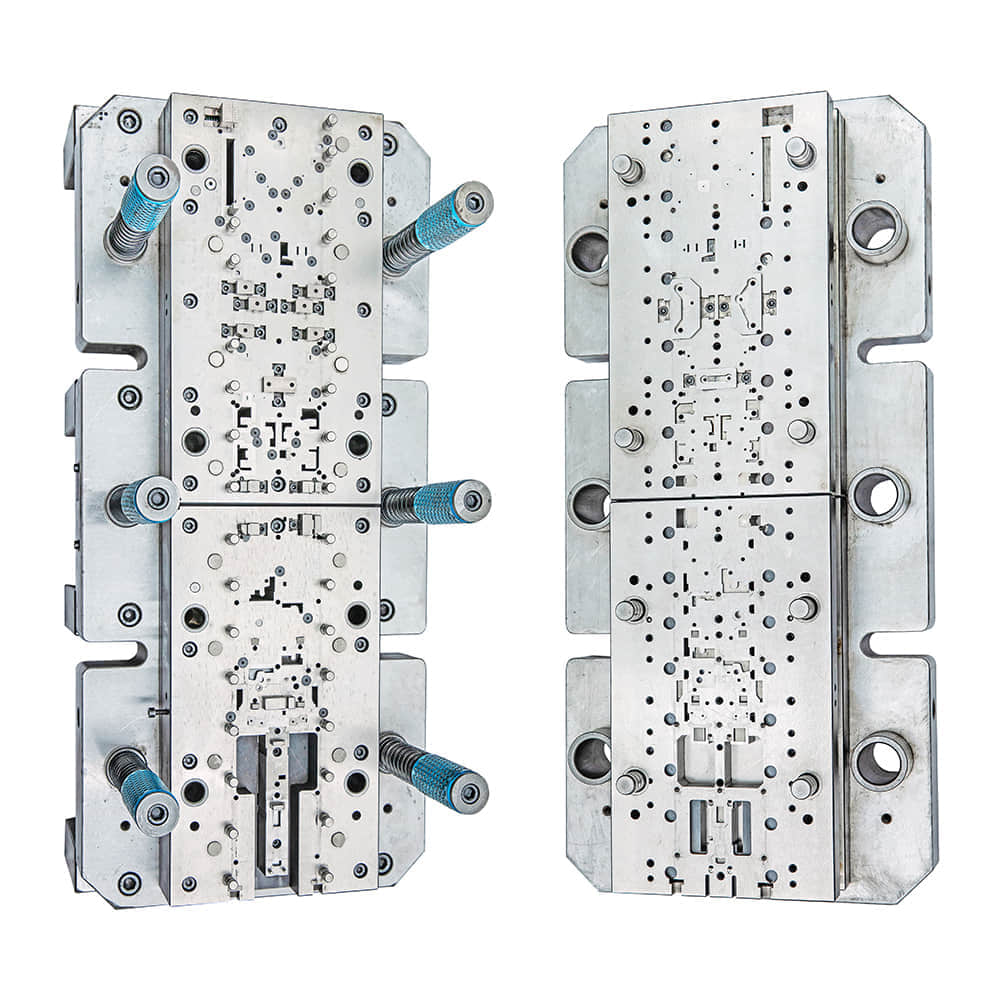

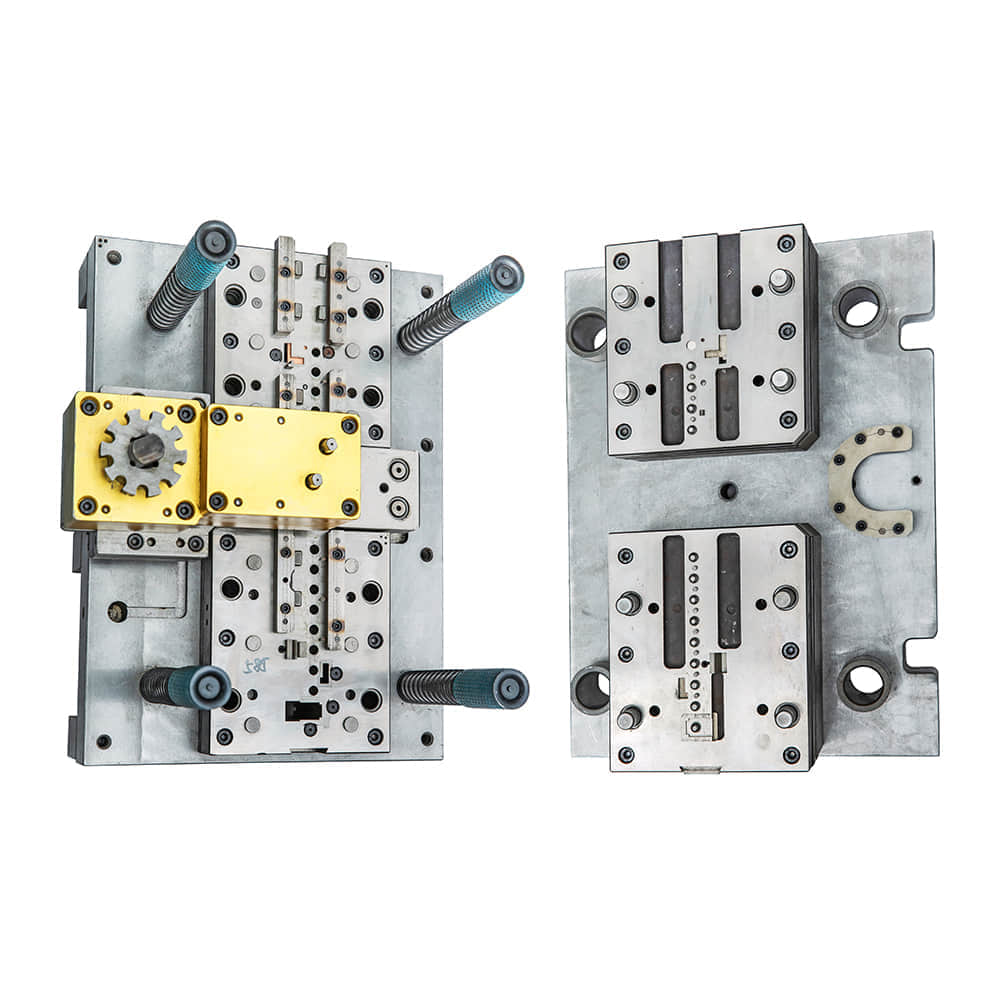

Metal stamping is a crucial process in the manufacturing industry, responsible for shaping and forming various metal components used in a wide range of products. At the heart of this process lies the metal stamping die, a precision tool that plays a pivotal role in creating high-quality metal parts. In this article, we will delve into the world of metal stamping die manufacturers, their significance, and the key factors that make them indispensable to the industry.

The Significance of Metal Stamping Die Manufacturers

Metal stamping die manufacturers are the unsung heroes of the manufacturing world. They are the artisans who craft the dies used to transform raw metal materials into intricate and precise components. These dies are essential for the mass production of items such as automotive parts, electronics, appliances, and countless other products we use daily. Precision and Customization One of the primary reasons metal stamping die manufacturers are indispensable is their ability to deliver precision and customization. Each manufacturing project comes with unique specifications, and metal stamping dies must be tailor-made to meet those exact requirements. Manufacturers work closely with their clients to design and fabricate dies that ensure the final product’s accuracy and consistency. Materials and Technology Metal stamping die manufacturers work with a variety of materials, including steel, aluminum, and alloys. The choice of material depends on the specific requirements of the project, such as the type of metal being stamped, the expected production volume, and the desired finish. Advancements in technology have enabled manufacturers to use computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to create highly complex dies with remarkable precision. Quality Control and Durability The quality of a metal stamping die directly impacts the quality of the stamped components. Manufacturers employ stringent quality control measures to ensure that their dies meet industry standards and client expectations. The durability of these dies is of paramount importance since they undergo repeated high-pressure cycles during the stamping process. Ensuring that the dies are made to withstand this rigorous wear and tear is a key focus for manufacturers. Innovation and Efficiency Metal stamping die manufacturers are constantly innovating to improve efficiency and reduce production costs. This involves developing new die designs, exploring advanced materials, and adopting automation and robotics in the manufacturing process. These innovations not only enhance the speed and precision of metal stamping but also contribute to sustainability by minimizing material waste. Global Reach The impact of metal stamping die manufacturers extends far beyond their immediate geographical locations. Many manufacturers have a global presence, serving clients around the world. This global reach enables industries in different regions to access the expertise and technology needed for high-quality metal stamping. Conclusion In the world of manufacturing, metal stamping die manufacturers are the unsung heroes who ensure that the products we use daily meet the highest standards of quality and precision. Their ability to create custom dies, employ advanced materials and technology, maintain strict quality control, and drive innovation makes them indispensable to the industry. As technology continues to evolve, we can expect metal stamping die manufacturers to play an even more pivotal role in shaping the future of manufacturing. Their contributions may go unnoticed by many, but their impact on the products we rely on is undeniable.