In the realm of modern manufacturing, injection molding has emerged as a cornerstone technique, enabling the creation of intricate and precise parts that are essential to various industries. An injection molded parts manufacturer plays a pivotal role in bringing ideas to life, producing components that range from everyday items to complex engineering solutions. This article delves into the fascinating world of injection molding, exploring its process, applications, and the significance of choosing the right manufacturer.

The Injection Molding Process

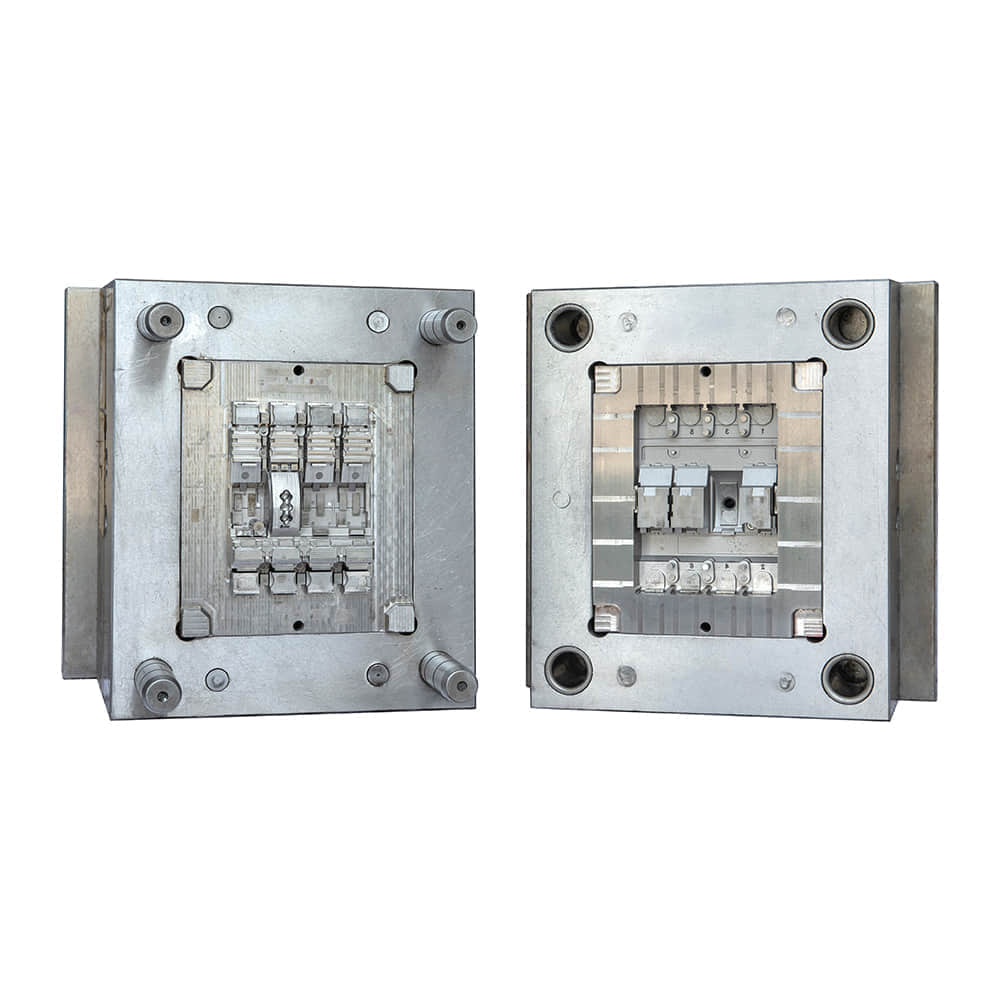

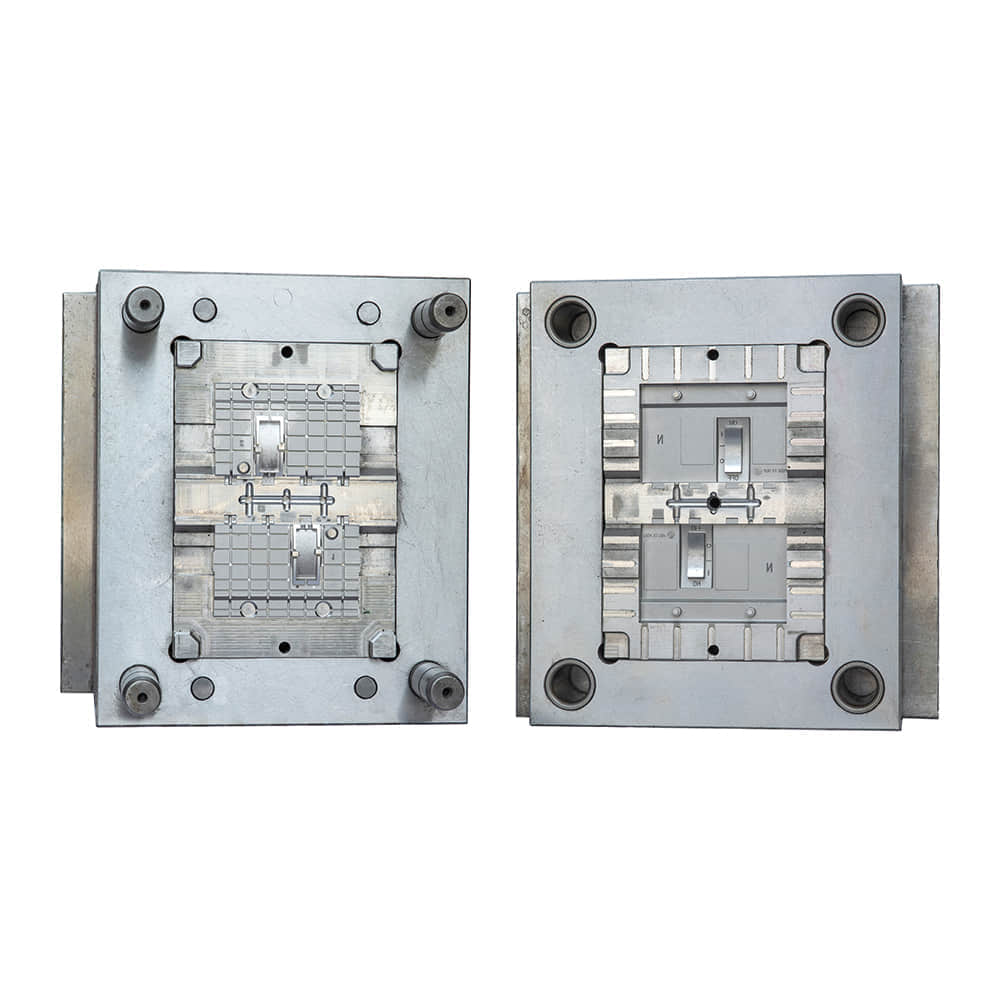

Injection molding is a manufacturing process that involves injecting molten material, typically plastic polymers, into a mold cavity. The molten material cools and solidifies within the mold, taking on its desired shape. This process offers numerous advantages, including high production efficiency, repeatability, and the ability to create intricate designs with minimal post-processing. The process begins with the design and creation of the mold, a crucial step that requires precision and expertise. The mold consists of two halves, the cavity and the core, which determine the final shape of the part. These molds are typically made from steel and are meticulously machined to ensure dimensional accuracy. Once the mold is ready, the chosen material is melted and injected under high pressure into the mold cavity. After cooling and solidification, the mold opens, and the newly formed part is ejected. Applications Across Industries Injection molded parts find their way into countless industries, touching nearly every aspect of our lives. In the consumer goods sector, they are used to manufacture items ranging from household containers to intricate toys. The medical field relies on injection molding for producing various medical devices due to its ability to meet stringent hygiene and precision requirements. The automotive industry benefits from injection molding by producing components such as interior panels, dashboards, and intricate engine parts. The technology’s influence extends to electronics manufacturing, where precision is paramount for producing components like casings, connectors, and even intricate parts for smartphones. The Role of the Manufacturer Selecting the right injection molded parts manufacturer is a critical decision that significantly impacts the quality and functionality of the final product. An experienced manufacturer brings expertise not only in the molding process but also in material selection, mold design, and post-processing techniques. Experienced manufacturers understand the importance of material selection for achieving the desired mechanical, thermal, and chemical properties. They can recommend the most suitable material for the intended application, balancing factors such as strength, durability, and cost-effectiveness. Mold design is another area where a proficient manufacturer shines. A well-designed mold minimizes defects, reduces cycle times, and ensures consistent part quality. Manufacturers with a deep understanding of mold flow analysis can optimize the mold’s geometry to avoid issues like warping, sink marks, and air traps. Conclusion Injection molding has revolutionized the manufacturing landscape, enabling the production of intricate and precise parts that are integral to various industries. From consumer goods to aerospace, injection molded parts play an indispensable role in shaping our world. Choosing a reliable and experienced injection molded parts manufacturer is key to ensuring the success of a project, from concept to final product. As technology continues to advance, it’s likely that injection molding will continue to push the boundaries of what’s possible, driving innovation and progress across industries.