Metal stamping, a cornerstone of modern manufacturing, has revolutionized the way intricate metal parts are produced. From automobiles to consumer electronics, metal stamping parts play a crucial role in various industries, enabling mass production of precise components with remarkable efficiency. In this article, we will delve into the world of metal stamping parts, exploring their significance, manufacturing process, and diverse applications.

The Significance of Metal Stamping Parts:

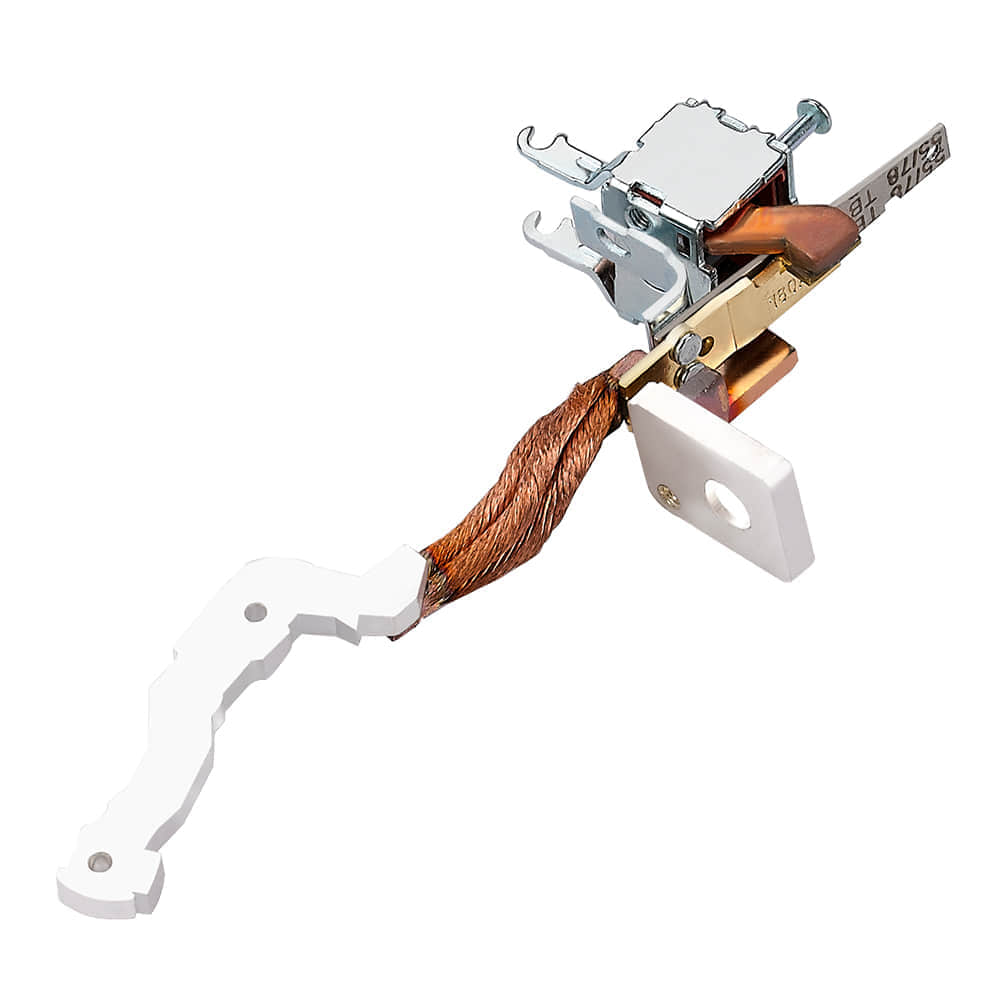

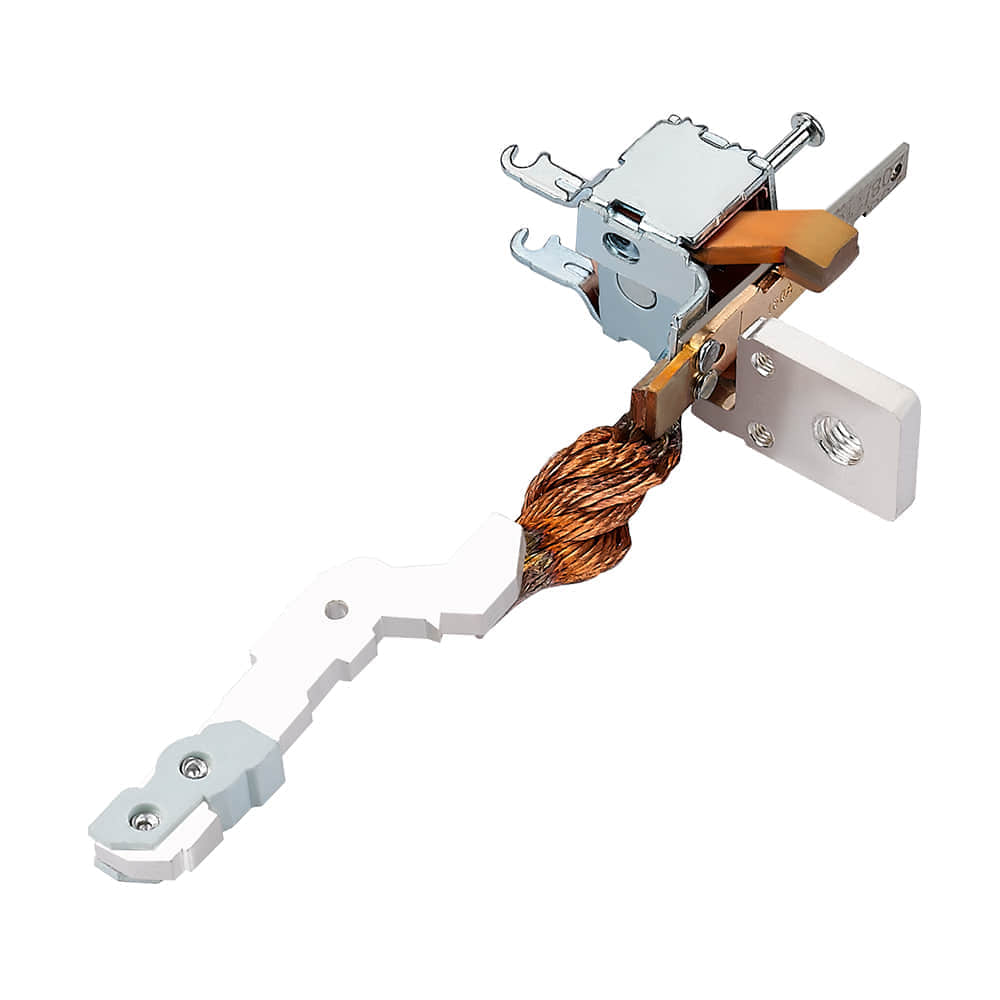

Metal stamping is a manufacturing process that involves shaping flat sheets of metal into desired forms using dies and presses. The resulting components, known as metal stamping parts, exhibit exceptional precision, uniformity, and consistency. This method offers a cost-effective solution for producing intricate parts in large quantities without compromising on quality. Industries ranging from aerospace and electronics to medical equipment harness the benefits of metal stamping to meet their complex manufacturing requirements. The Manufacturing Process: The process of creating metal stamping parts involves several stages, each contributing to the final product’s accuracy and durability. Here’s a breakdown of the typical steps involved: Design and Prototyping:Engineers create detailed designs and prototypes of the desired components, ensuring that every intricate detail is accounted for. Material Selection:The choice of metal alloy is critical, as it affects the part’s characteristics such as strength, conductivity, and corrosion resistance. Blanking:The initial sheet of metal is cut into smaller, flat pieces known as blanks. This is often done using high-precision mechanical or laser cutting methods. Stamping:Blanks are placed between the dies in a press. The press applies high force to shape the metal into the desired form. This can involve multiple operations, such as bending, punching, and coining. Forming:Additional processes like bending, drawing, and stretching can be performed to achieve the final shape and dimensions. Finishing:Surface treatments such as plating, painting, or powder coating are applied to enhance the part’s appearance and protect it from corrosion. Quality Control:Each stamped part undergoes rigorous quality checks to ensure it meets the specified tolerances and standards. Diverse Applications: Metal stamping parts find their applications in a wide range of industries, contributing to the functionality and aesthetics of various products. Some notable applications include: Automotive Industry:Metal stamping produces intricate components for engines, transmissions, chassis, and interiors, contributing to the overall performance and safety of vehicles. Electronics and Appliances:From smartphones to refrigerators, metal stamping parts are integral to the structural integrity and functionality of electronic devices and household appliances. Aerospace Sector:Critical aerospace components requiring high strength and precision are manufactured using metal stamping, ensuring the safety and efficiency of aircraft. Medical Equipment:Metal stamping produces parts for medical devices, implants, and surgical instruments, where precision and biocompatibility are paramount. Construction and Infrastructure:Many architectural and construction elements, such as brackets, hinges, and panels, are manufactured through metal stamping. Conclusion: In the realm of modern manufacturing, metal stamping parts stand as a testament to human innovation and engineering prowess. The ability to create intricate, high-quality components in bulk has transformed industries and shaped the products that define our lives. As technology advances, metal stamping techniques continue to evolve, promising even greater precision, efficiency, and versatility in the production of essential components across various sectors.