Damper actuators are essential components in various industrial and HVAC systems, providing automated control for regulating airflow, temperature, and pressure. As energy efficiency and environmental sustainability become increasingly important, the demand for precise and reliable damper actuators has been on the rise. These actuators are used to open and close dampers, which are critical in controlling ventilation and air circulation within large systems like commercial buildings, power plants, and manufacturing facilities. In this article, we will explore the role of damper actuator manufacturers, the types of actuators they produce, and the factors that influence their design and performance.

The Role of Damper Actuator Manufacturers

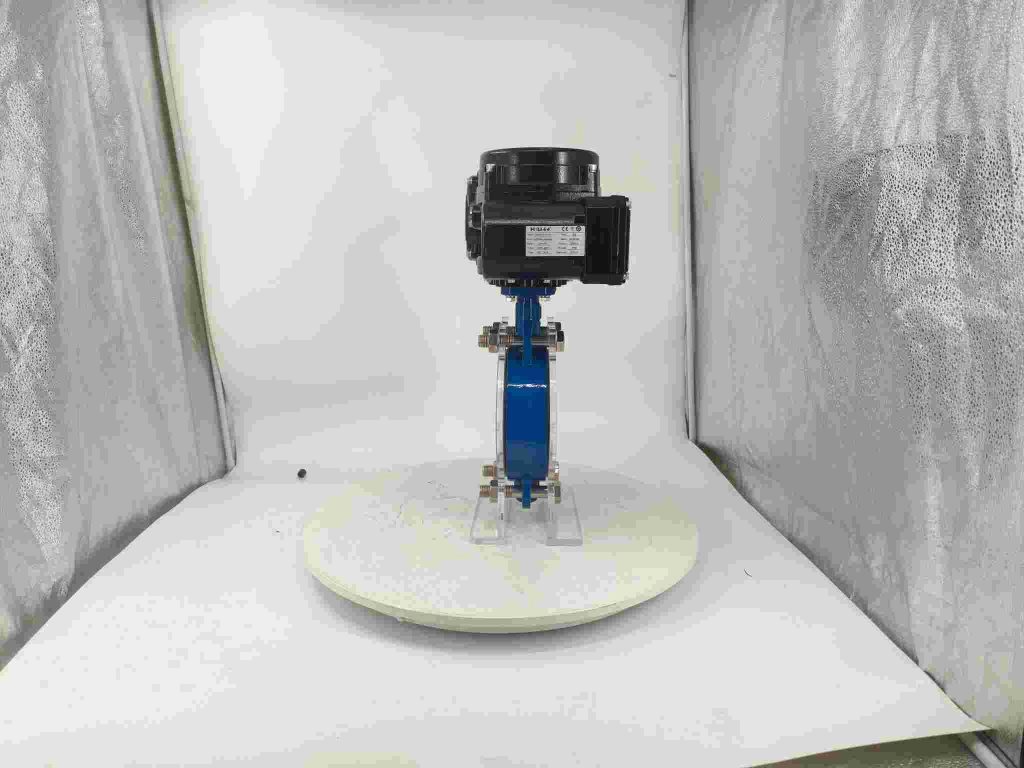

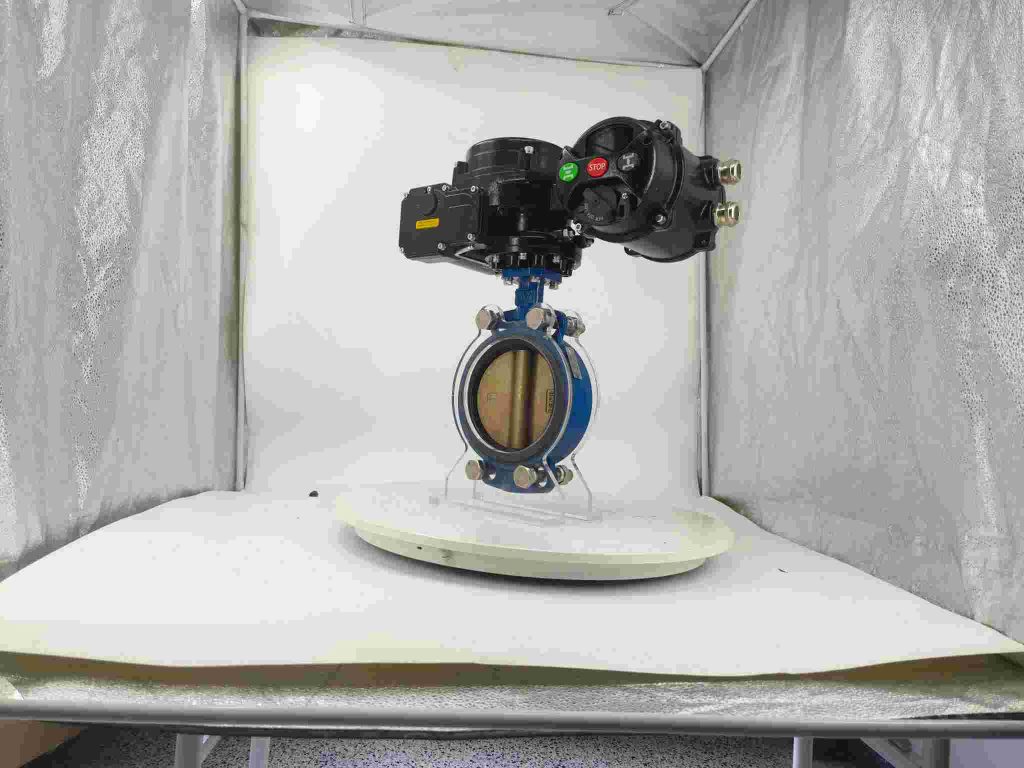

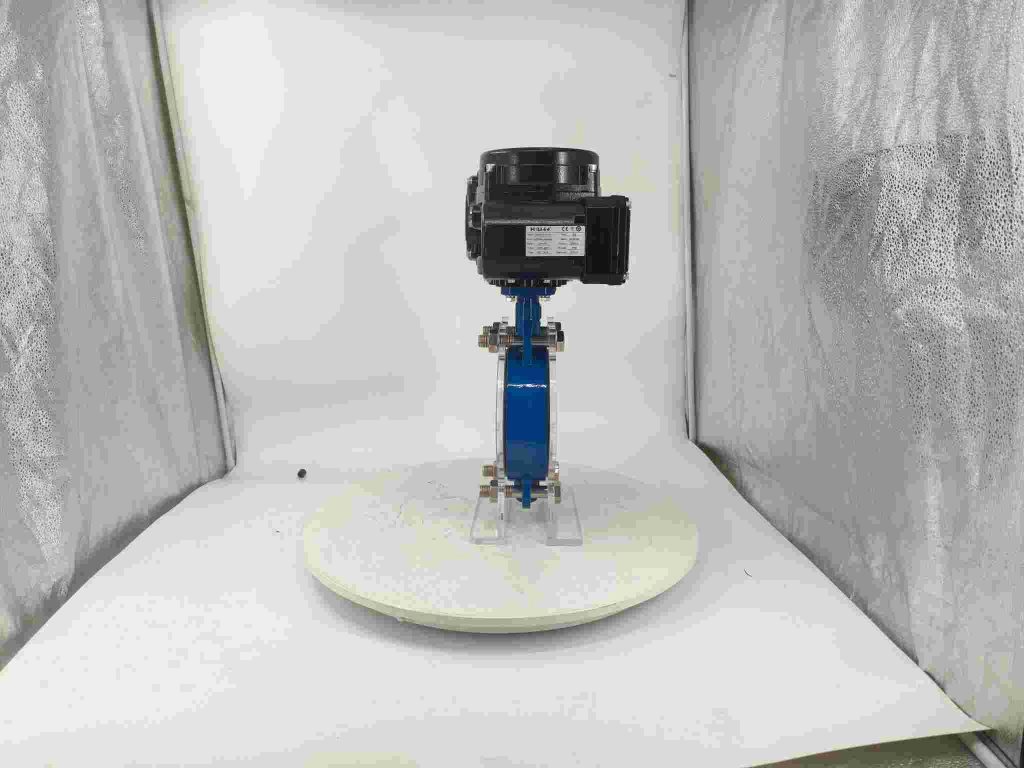

Damper actuators are designed to operate dampers, which are mechanical devices that control the flow of air or other gases within ducts or pipes. Actuators are responsible for moving the damper blades, either to allow more air to flow through or to block it completely, depending on the system’s requirements. These actuators must be highly reliable, capable of withstanding varying temperatures, pressures, and environmental conditions, making their design a critical element of their functionality. Damper actuator manufacturers are tasked with developing products that meet the specific demands of different industries, from HVAC to energy production. These manufacturers focus on producing actuators that not only ensure optimal damper control but also provide longevity and minimal maintenance, which can significantly reduce the operational costs of the systems they are part of.