In the rapidly evolving world of energy storage, lithium-ion batteries have emerged as one of the most prominent power solutions due to their high energy density, long lifespan, and versatile applications. However, with these benefits come significant safety concerns, especially when it comes to high-energy devices like lithium-ion batteries, which can pose a risk of explosion or fire if not properly managed. This is where explosion-proof lithium battery valves come into play. These safety components are crucial for ensuring that lithium-ion batteries operate safely under a wide range of conditions, protecting both the device and its user.

Understanding Explosion-proof Lithium Battery Valves

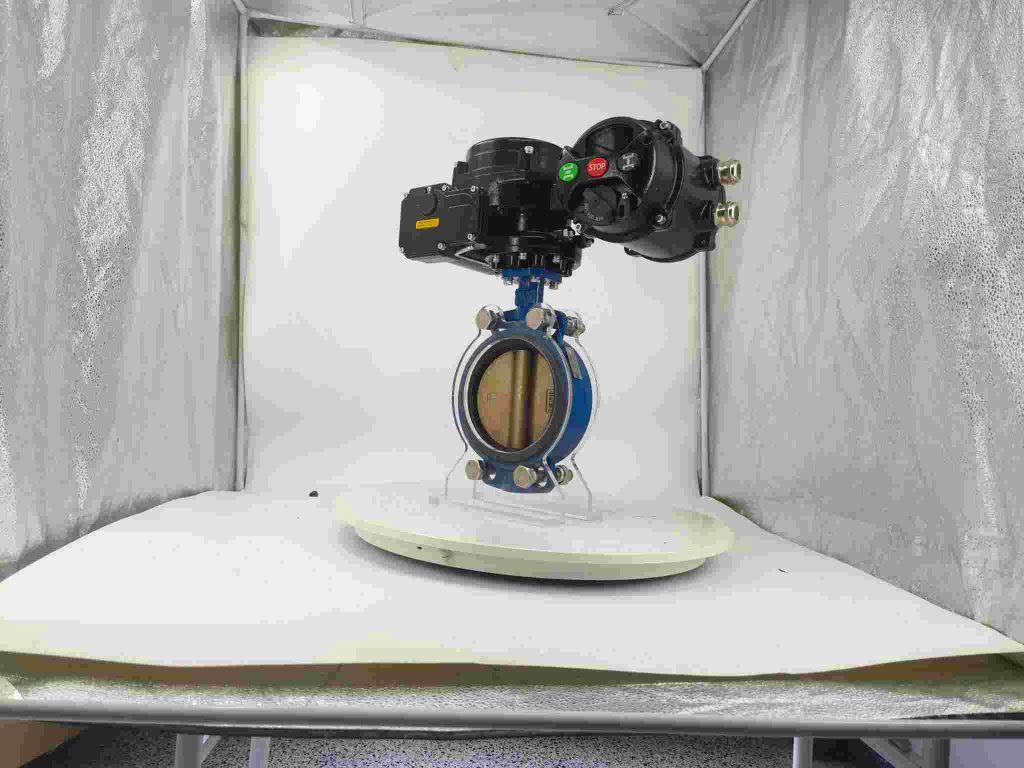

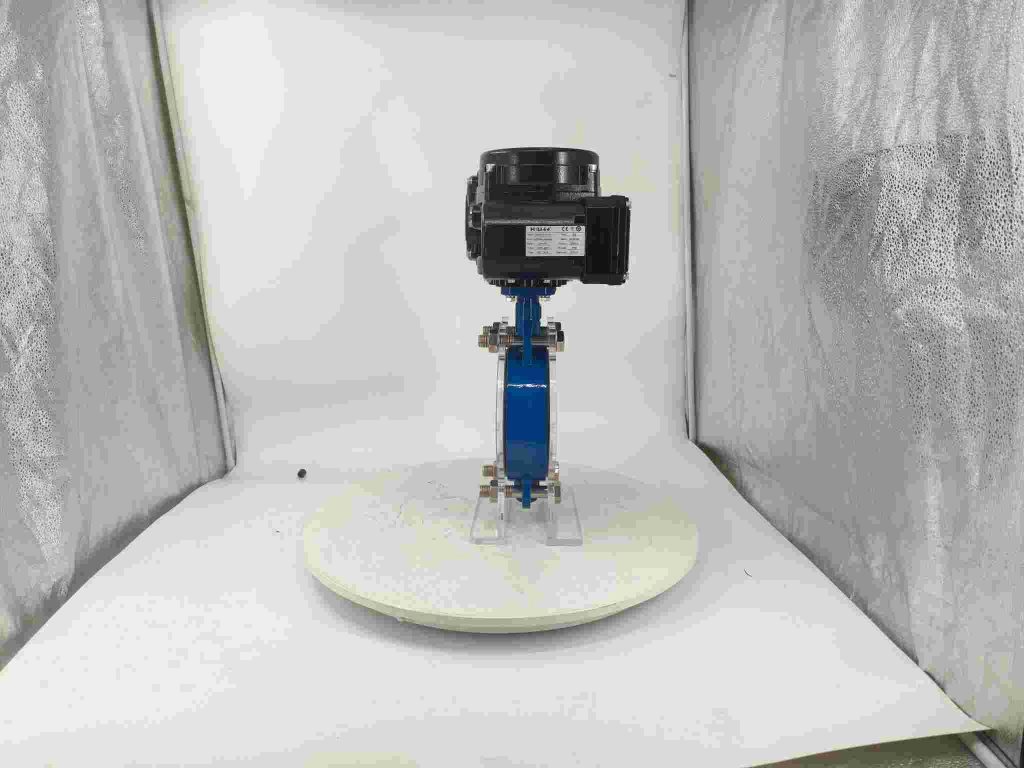

Explosion-proof lithium battery valves are essential components designed to protect lithium-ion batteries from dangerous situations that may arise due to overpressure or temperature extremes. These valves are engineered to release pressure when a battery’s internal pressure exceeds a critical threshold, preventing the risk of rupture, leakage, or catastrophic failure. They are typically made from durable materials capable of withstanding the harsh conditions often associated with lithium-ion battery use, such as high temperatures and electrical stress. The role of the valve is to act as a safety mechanism that ensures the battery’s internal pressure remains within safe limits. When pressure builds up due to thermal runaway, chemical reactions, or external impacts, the valve opens to vent gases and relieve pressure. This process not only prevents explosions but also reduces the likelihood of fire hazards, making the valve an integral part of a battery’s overall safety system.