Pneumatic ball valves are essential components in fluid control systems, widely used in industries such as oil and gas, chemicals, pharmaceuticals, water treatment, and many others. These valves offer precise control over the flow of liquids or gases, ensuring efficient and reliable operation in various industrial applications. A Pneumatic Ball Valve OEM (Original Equipment Manufacturer) manufacturer plays a pivotal role in the production and supply of these crucial valves, providing customized solutions to meet the specific needs of clients across the globe. In this article, we will explore the importance of pneumatic ball valve OEM manufacturers and their contribution to enhancing fluid control systems.

What is a Pneumatic Ball Valve?

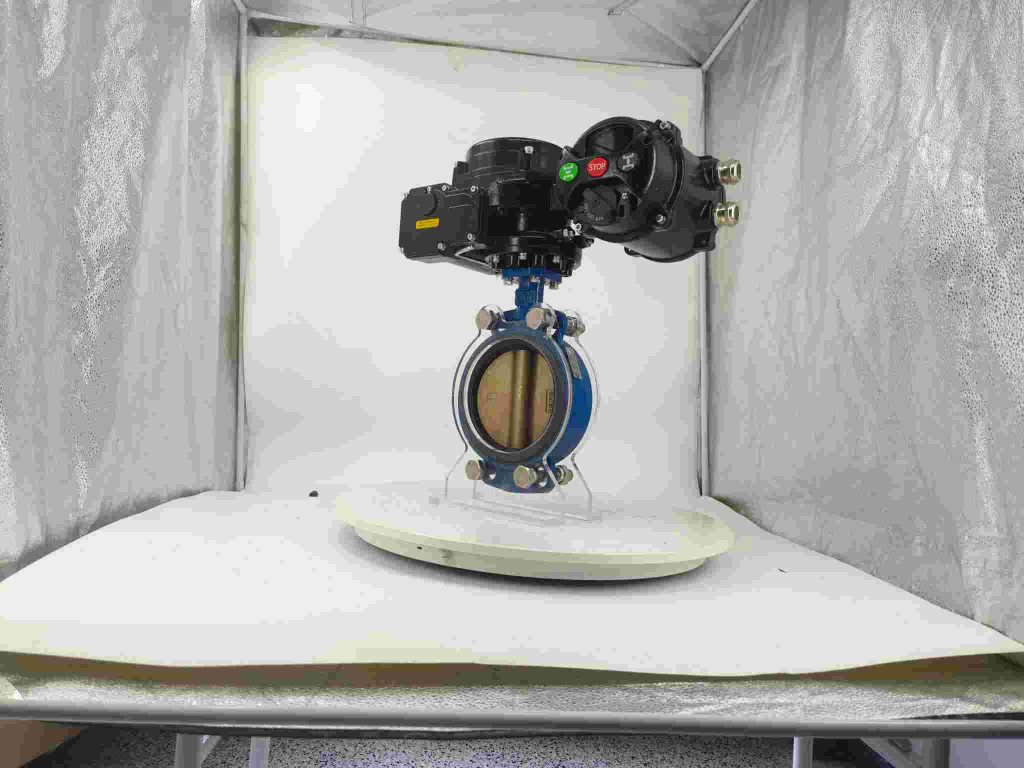

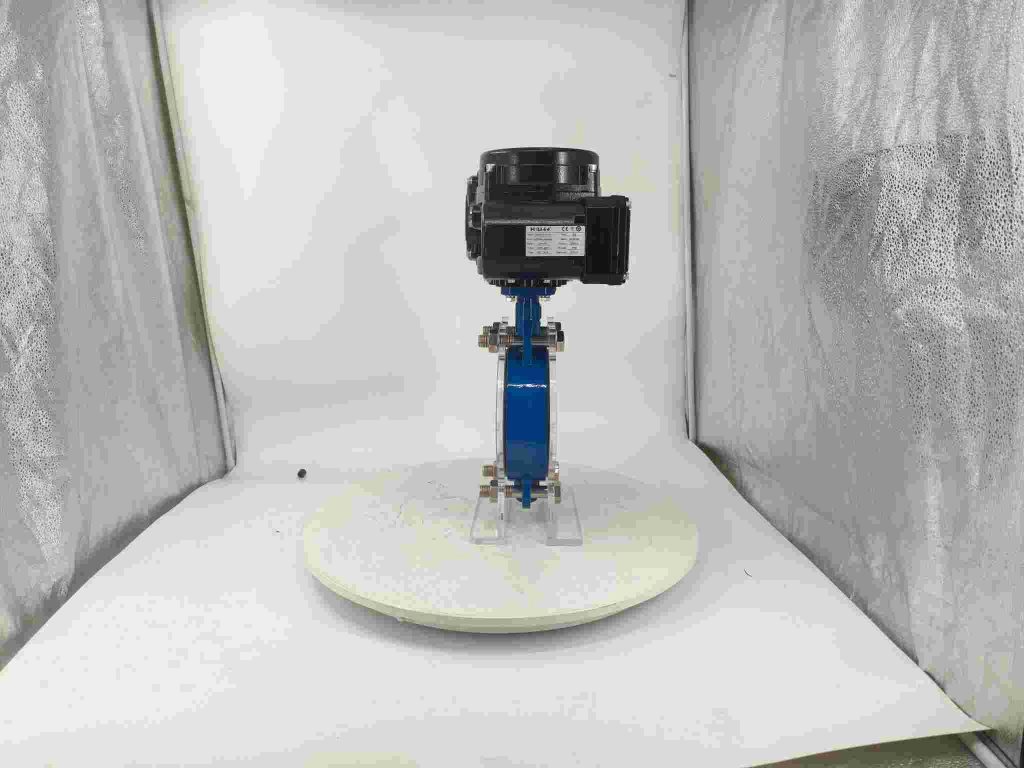

A pneumatic ball valve is a type of valve that uses compressed air to actuate the movement of a ball, which is housed inside the valve body. The ball has a hole in the center, which can be rotated to allow or stop the flow of fluid. When the pneumatic actuator receives air pressure, it rotates the ball valve to the desired position—open or closed. These valves are known for their high-performance characteristics, such as tight sealing, quick response time, and the ability to handle high pressures and temperatures. The Role of an OEM Manufacturer OEM manufacturers specialize in producing high-quality components for companies that require custom-designed parts for their operations. In the case of pneumatic ball valves, an OEM manufacturer plays an essential role in designing, developing, and producing valves that meet the specific requirements of their clients. These requirements may vary depending on the industry, the type of fluid being controlled, and the desired specifications such as pressure rating, temperature range, and material composition.