In the world of electrical engineering, the Moulded Case Circuit Breaker (MCCB) plays a crucial role in ensuring safe and reliable power distribution. China, a global leader in electronics manufacturing, is a key supplier of these vital components. In this article, we delve into the intricacies of Moulded Case Circuit Breakers, explore the competitive landscape of China’s suppliers, and identify factors to consider when selecting a supplier.

Moulded Case Circuit Breakers are essential components in any electrical system, providing protection against overcurrent and short-circuit conditions. They act as safety barriers, preventing damage to electrical equipment and safeguarding personnel. As demand for these devices increases worldwide, China’s suppliers have risen to the challenge, offering a range of high-quality products at competitive prices.

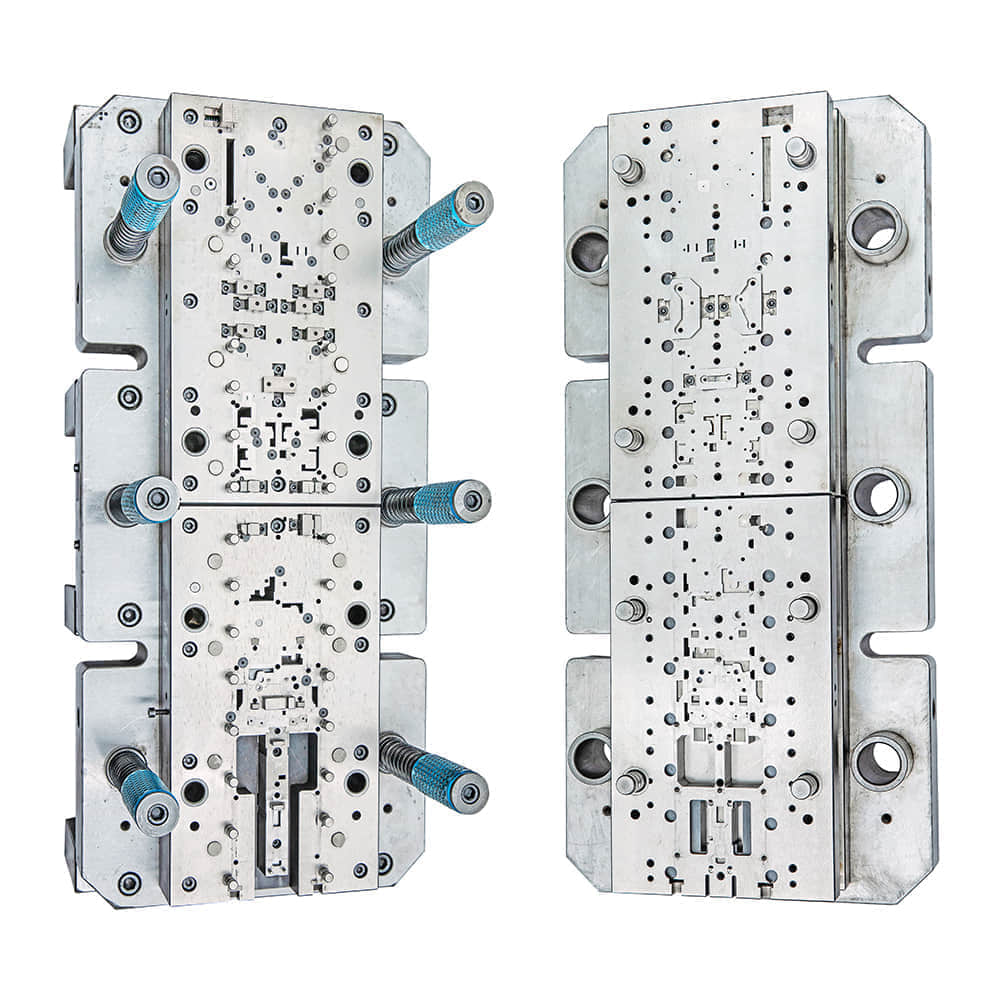

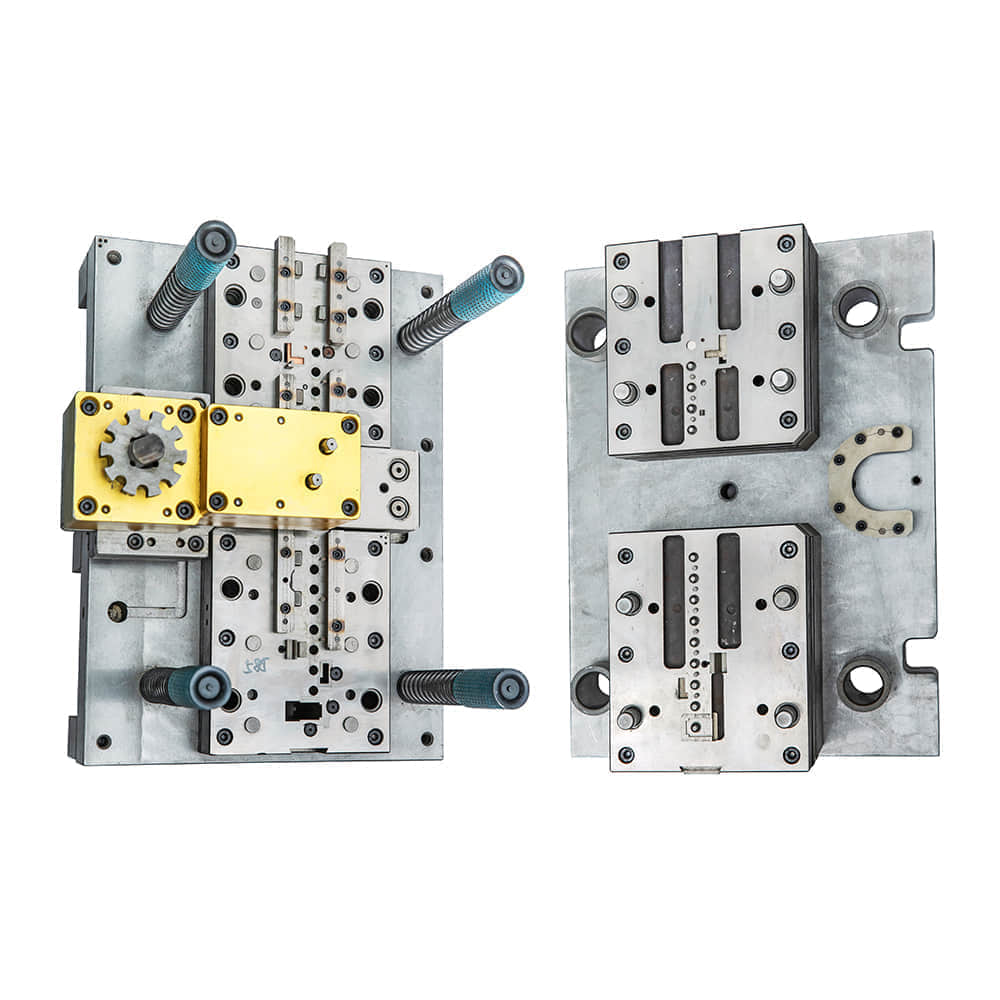

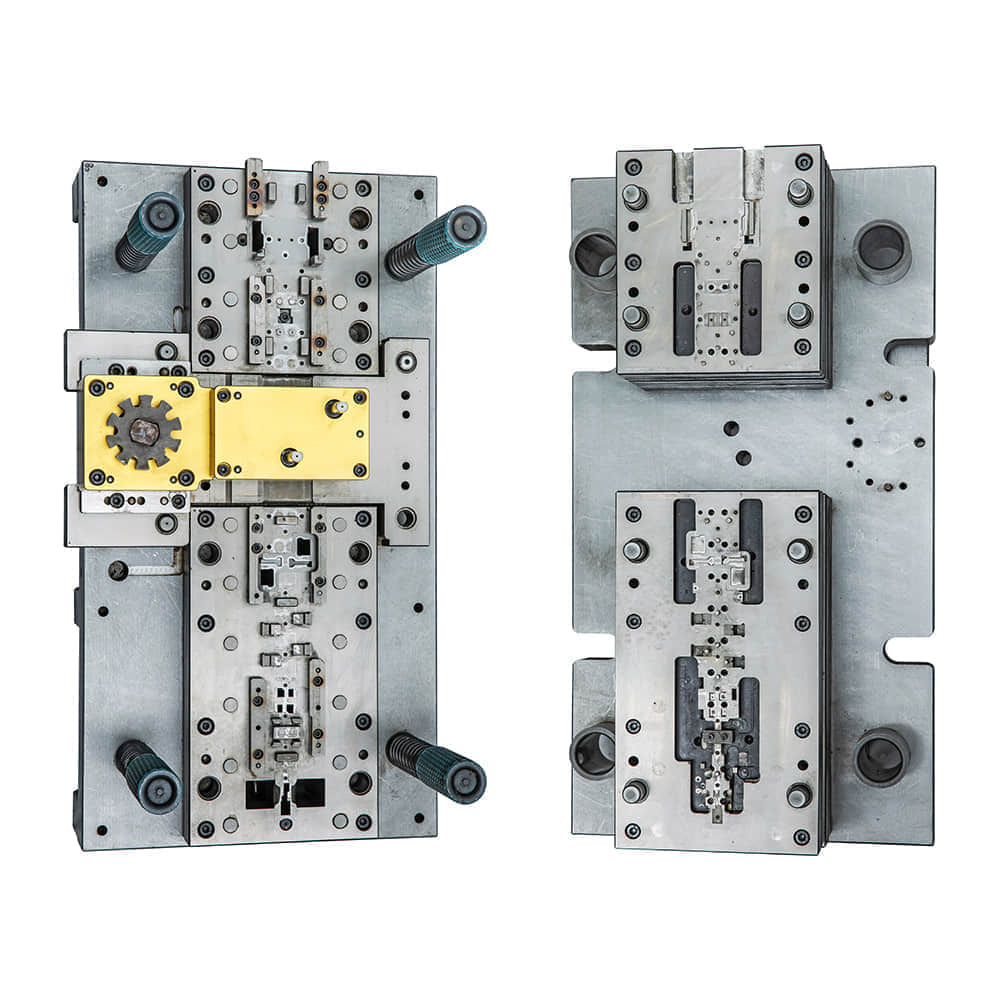

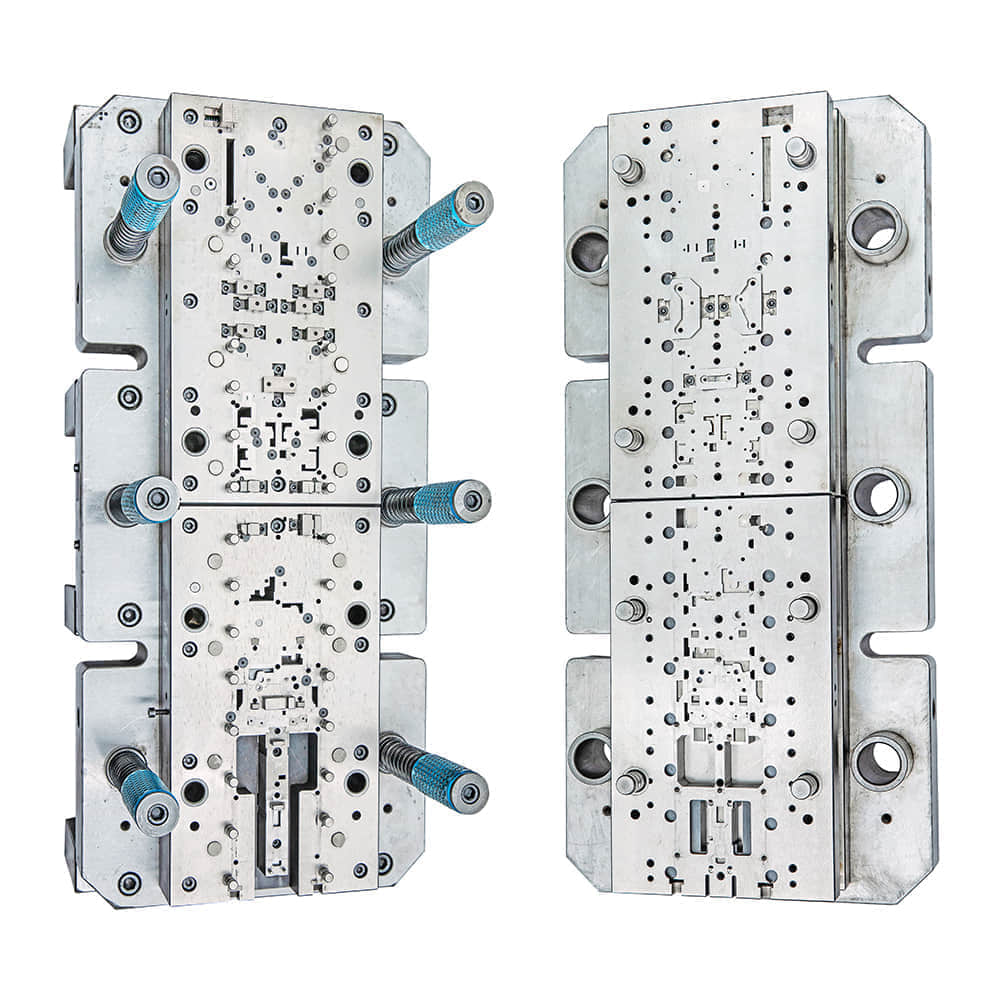

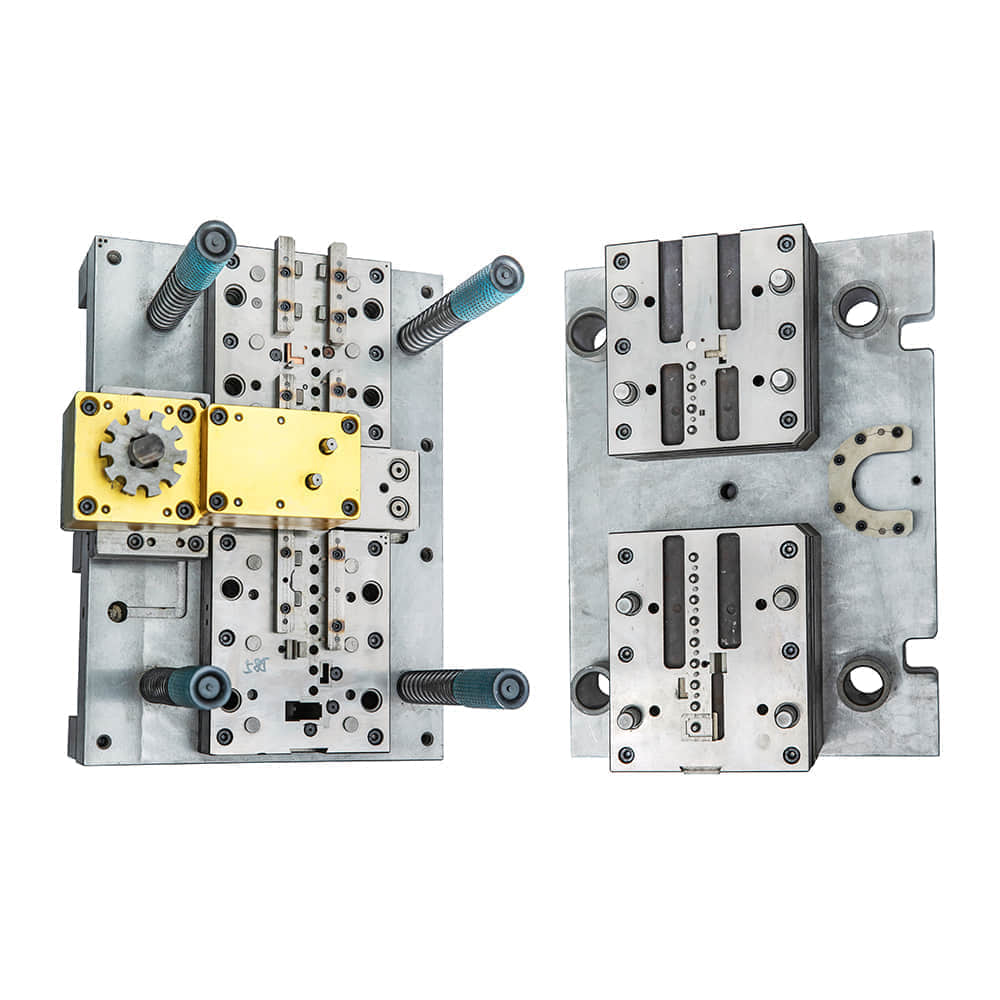

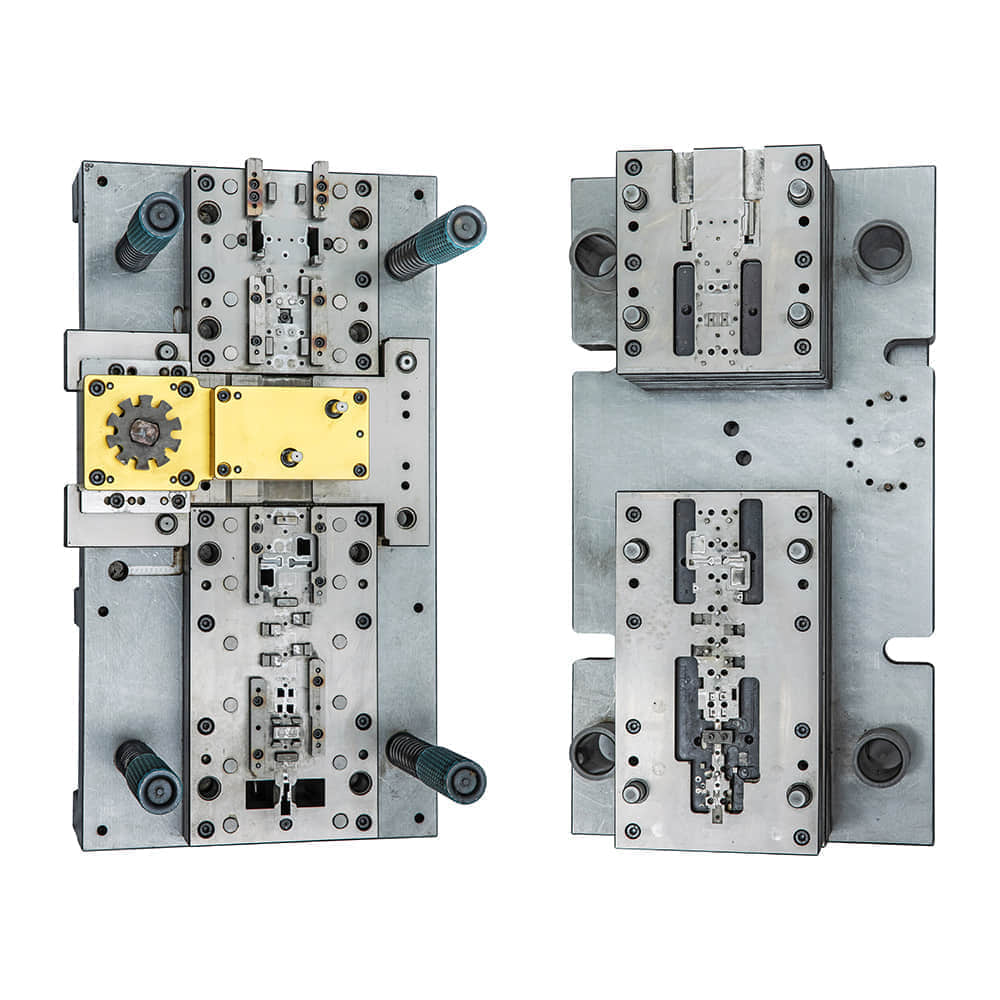

The Chinese suppliers of Moulded Case Circuit Breakers offer diverse products catering to different applications and industries. From small-scale residential applications to large-scale industrial setups, Chinese suppliers have honed their expertise to meet specific customer needs. Many of these suppliers have also invested in research and development, introducing innovative features and materials that enhance the performance and reliability of MCCBs. When selecting a Moulded Case Circuit Breaker China supplier, several factors should be considered. Firstly, product quality is paramount. Look for suppliers who use high-grade materials and adhere to international quality standards. Secondly, it’s essential to evaluate a supplier’s technical capabilities, including their design, manufacturing, and testing processes. This ensures that the products meet the desired performance standards.