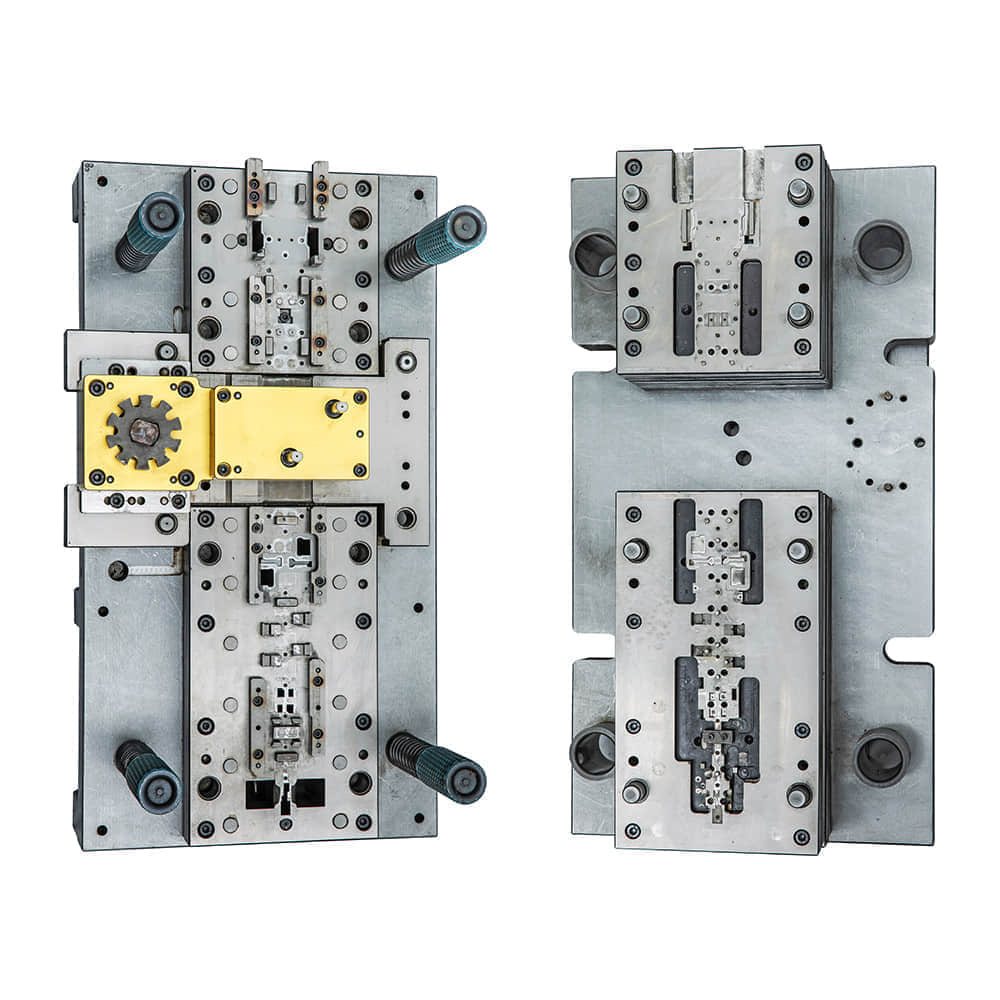

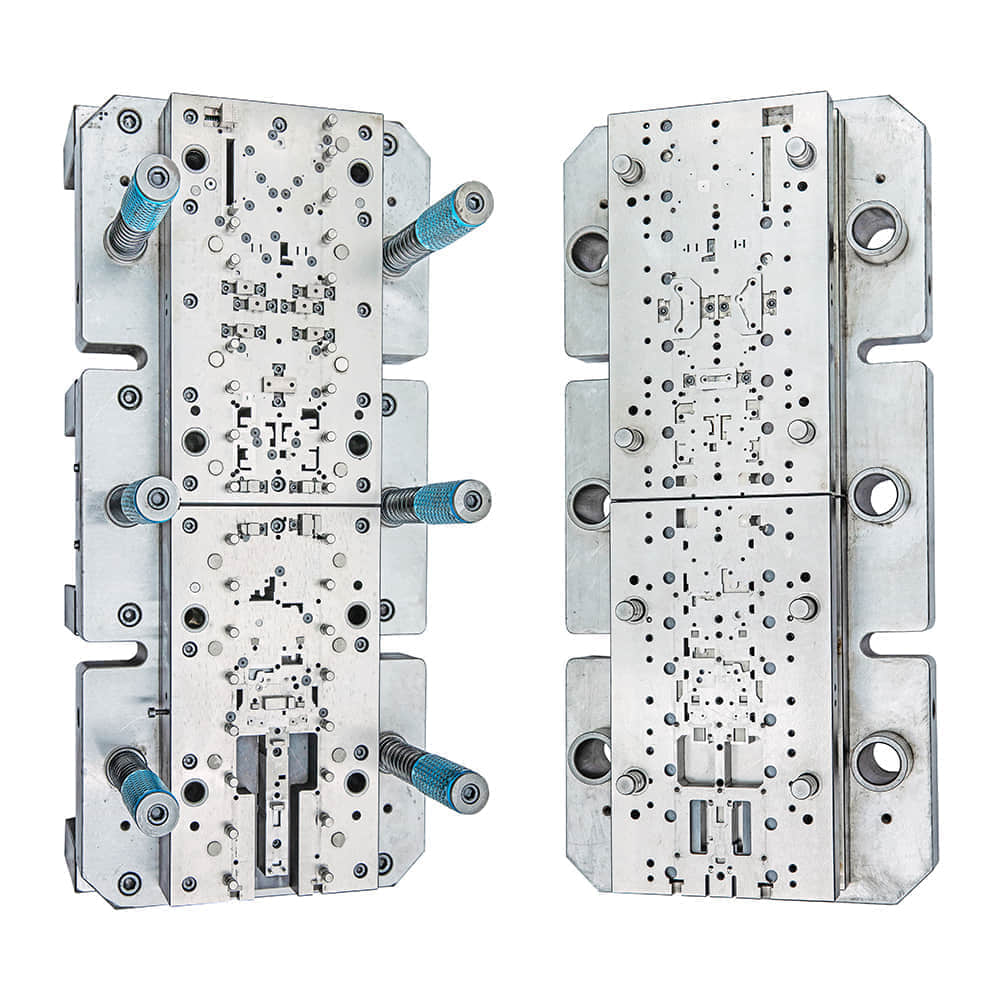

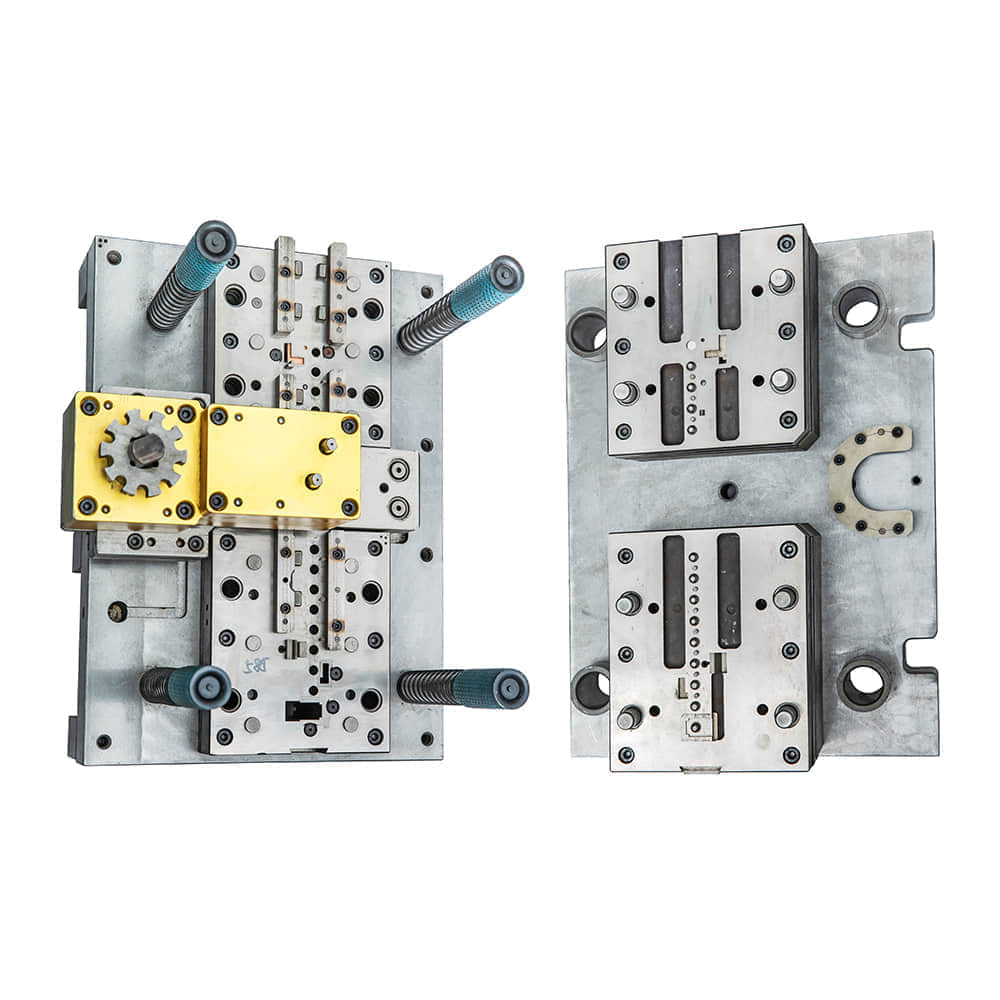

China Hardware Mold Manufacturer: Leading the Way in Precision Engineering

In the heart of the world’s manufacturing hub, China stands tall as a global leader in hardware mold manufacturing. With its unwavering commitment to precision engineering and cutting-edge technology, China Hardware Mold Manufacturers have earned a stellar reputation for producing top-quality molds used in various industries worldwide. In this article, we will explore the key factors that have contributed to China’s success in this field and delve into the excellence that defines these manufacturers.

State-of-the-Art Technology: China Hardware Mold Manufacturers have invested heavily in state-of-the-art technology, allowing them to create molds with unparalleled precision and efficiency. Computer Numerical Control (CNC) machines, 3D printing, and advanced CAD/CAM software are just a few examples of the tools they employ to ensure the highest quality products. Skilled Workforce: The backbone of China’s hardware mold industry is its skilled workforce. Manufacturers here understand the intricacies of mold making and have a deep knowledge of materials, processes, and design principles. Continuous training and development programs ensure that these professionals stay at the forefront of the industry. Strict Quality Control: Quality is non-negotiable for China Hardware Mold Manufacturers. Rigorous quality control measures are implemented at every stage of production to ensure that each mold meets or exceeds international standards. This commitment to quality has won them the trust of clients worldwide. Customization and Innovation: China’s manufacturers excel in customization and innovation. They work closely with clients to design and create molds that precisely match their specifications. Additionally, they stay ahead of industry trends and continuously innovate to meet the evolving needs of various sectors, including automotive, electronics, and consumer goods. Competitive Pricing: While maintaining top-notch quality, China Hardware Mold Manufacturers offer competitive pricing. This combination of quality and affordability has made them the preferred choice for businesses seeking to reduce production costs without compromising on excellence. Global Reach: China’s hardware mold manufacturers have a global reach, exporting their products to virtually every corner of the world. Their ability to navigate complex international trade regulations and offer reliable shipping options has contributed to their widespread success. Environmental Responsibility: In an era of increasing environmental consciousness, these manufacturers have embraced sustainable practices. Many have adopted eco-friendly materials and manufacturing processes, reducing their carbon footprint and aligning with global sustainability goals. Comprehensive Services: China Hardware Mold Manufacturers offer comprehensive services, from initial design and prototyping to mold production and maintenance. This one-stop-shop approach simplifies the manufacturing process for clients and ensures a seamless experience. Rapid Turnaround: Time is money in the manufacturing industry. China’s manufacturers understand this and are known for their ability to provide rapid turnaround times without compromising on quality. This efficiency is especially valuable for businesses with tight production schedules. Strategic Partnerships: China’s manufacturers have forged strategic partnerships with clients, creating long-lasting relationships built on trust and mutual success. These partnerships often extend beyond a single project, with manufacturers becoming trusted collaborators in clients’ ongoing ventures. In conclusion, China Hardware Mold Manufacturers have risen to prominence on the global stage due to their unwavering commitment to precision, innovation, and quality. Their ability to combine cutting-edge technology with a skilled workforce, competitive pricing, and a global reach makes them an indispensable resource for businesses across industries. As the world of manufacturing continues to evolve, these manufacturers are well-positioned to lead the way, setting new standards for excellence in hardware mold production.