China has long been a global leader in manufacturing, and one sector that exemplifies this prowess is the hardware mold industry. With a rich history of craftsmanship and a relentless drive for innovation, China’s hardware mold manufacturers have carved out a niche for themselves on the world stage. In this article, we will explore the key aspects of China’s hardware mold manufacturing industry and its impact on various sectors.

A Legacy of Precision:

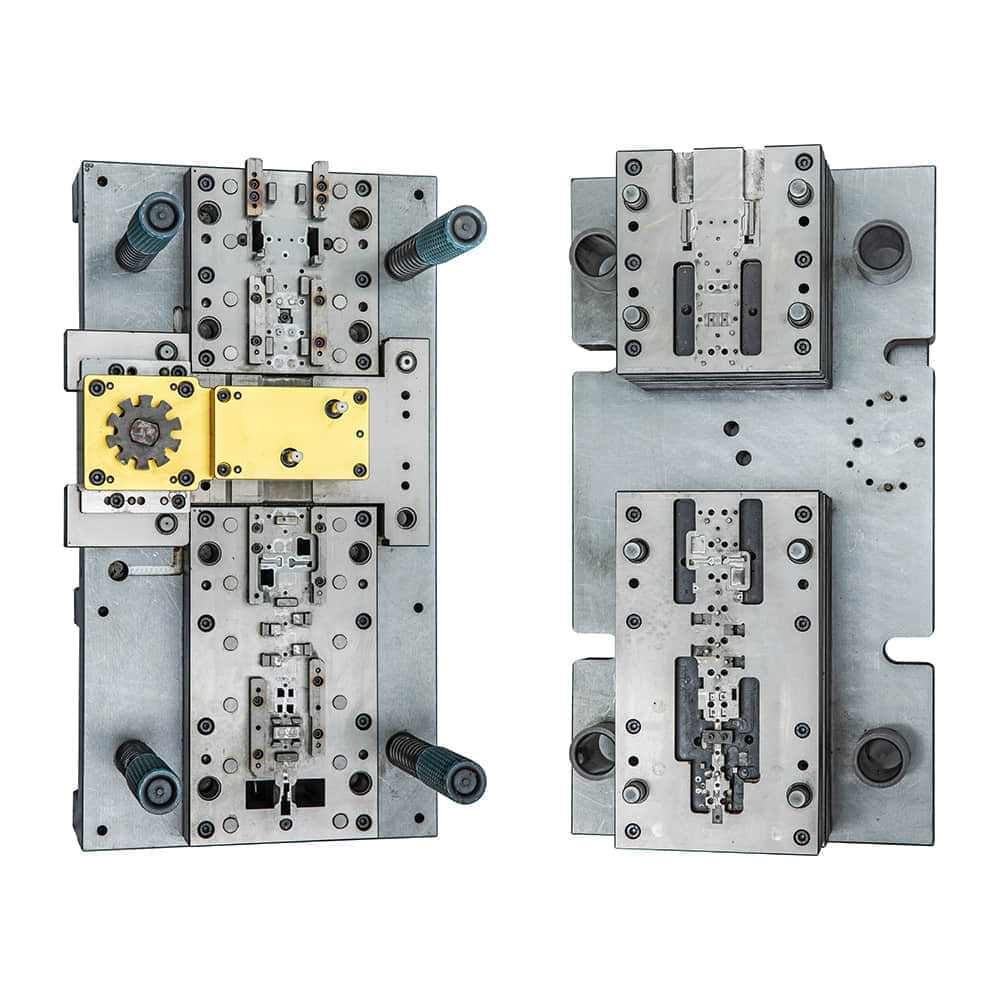

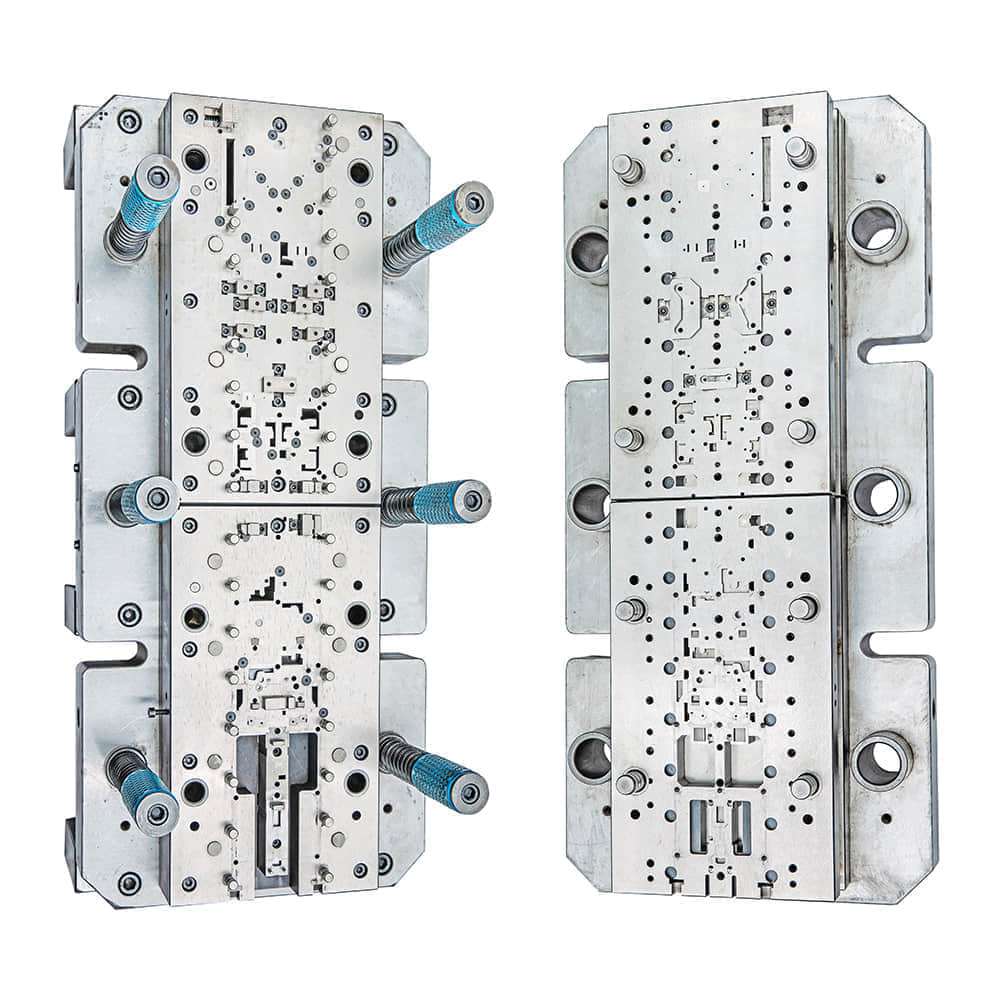

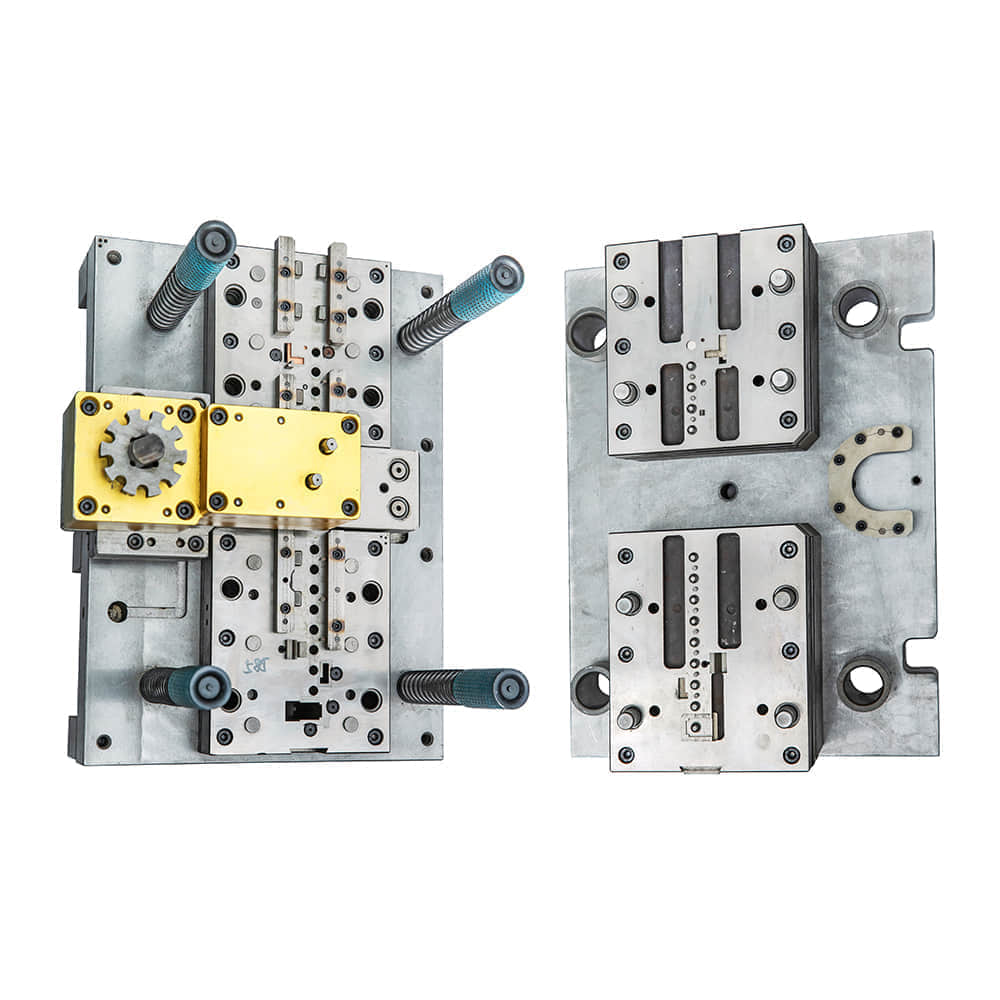

China’s hardware mold manufacturers have a legacy that dates back several decades. The industry has evolved from small, family-owned workshops to large-scale production facilities equipped with state-of-the-art technology. This evolution has been driven by a commitment to precision engineering, an essential aspect of producing high-quality molds. Innovation as a Driving Force: Innovation is the lifeblood of any industry, and China’s hardware mold manufacturers understand this well. They invest heavily in research and development, constantly pushing the boundaries of what is possible. This commitment to innovation has resulted in the development of cutting-edge mold designs and production techniques. Diverse Applications: Hardware molds play a crucial role in the production of a wide range of products, from automotive components to consumer electronics. China’s hardware mold manufacturers cater to a diverse set of industries, providing customized solutions that meet the unique requirements of each sector. Global Reach: China’s hardware mold manufacturers have a strong global presence. They export their products to countries around the world, earning a reputation for delivering high-quality molds at competitive prices. This global reach has made them indispensable partners for businesses looking to streamline their production processes. Quality Control: Quality control is a top priority for China’s hardware mold manufacturers. They adhere to stringent quality standards, ensuring that every mold produced meets the highest levels of precision and durability. This commitment to quality has earned them the trust of clients worldwide. Environmental Responsibility: In recent years, there has been a growing emphasis on environmental responsibility in manufacturing. China’s hardware mold manufacturers have responded to this call by adopting eco-friendly production processes and materials. They are committed to reducing their environmental footprint while delivering exceptional products. Skilled Workforce: A skilled workforce is the backbone of any manufacturing industry, and China’s hardware mold manufacturers are no exception. They invest in training and development programs to ensure that their employees possess the necessary skills and expertise to deliver top-notch results. Embracing Technology: Technology is rapidly changing the manufacturing landscape, and China’s hardware mold manufacturers are at the forefront of this transformation. They incorporate advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) into their processes, enhancing precision and efficiency. A Bright Future Ahead: As we look to the future, China’s hardware mold manufacturers are poised for even greater success. Their dedication to precision, innovation, and quality control will continue to drive the industry forward. With a global reach and a commitment to sustainability, they are well-positioned to meet the evolving needs of industries worldwide. In conclusion, China’s hardware mold manufacturers have established themselves as leaders in the global manufacturing landscape. Their legacy of precision, commitment to innovation, and dedication to quality control make them invaluable partners for businesses across various sectors. As they continue to embrace technology and environmental responsibility, the future looks bright for this dynamic industry.