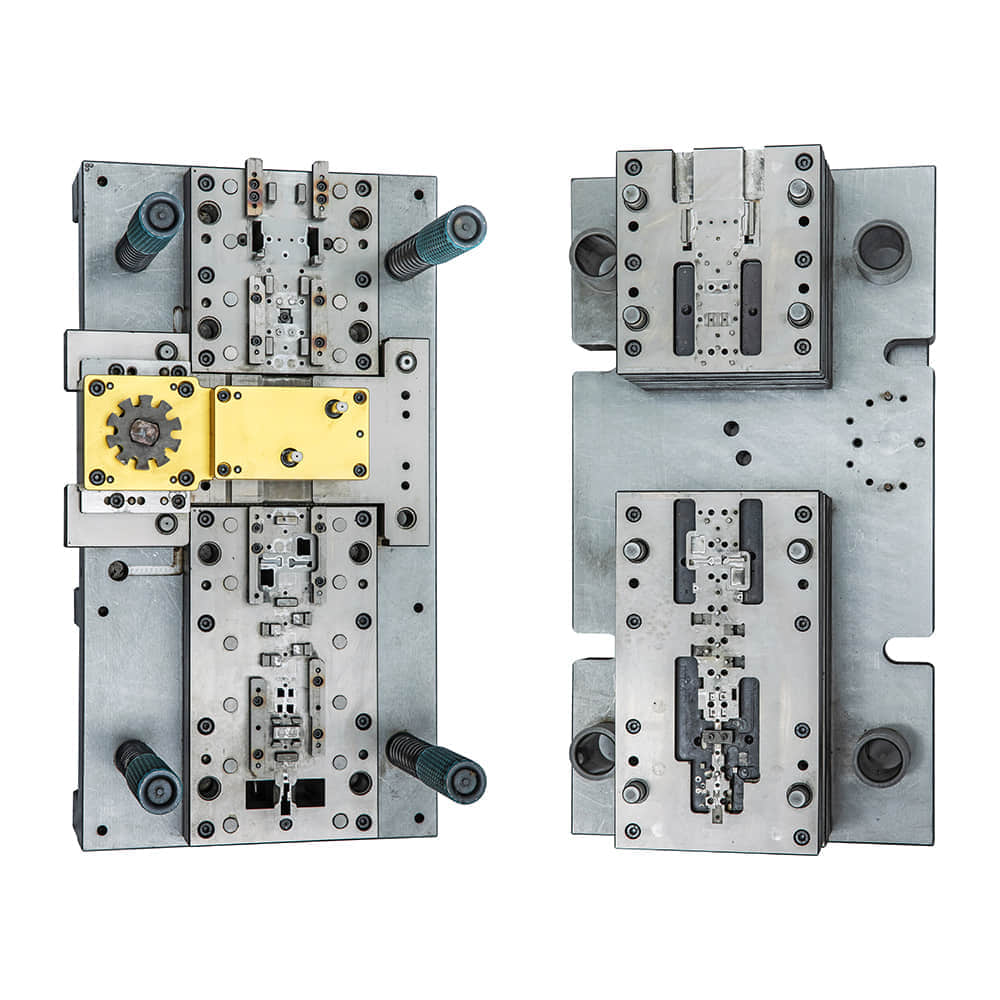

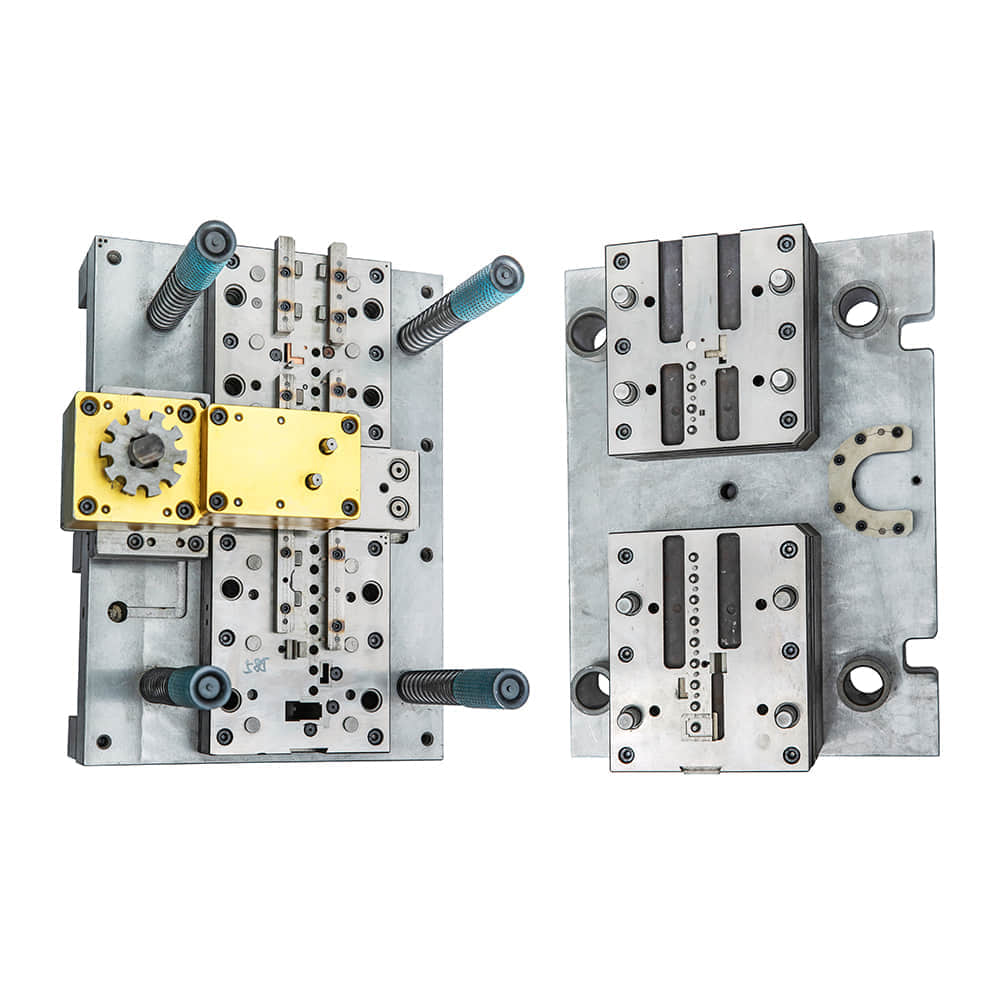

In the realm of metal fabrication, precision and efficiency are paramount. Among the many tools and techniques at the disposal of manufacturers, metal stamping dies play a pivotal role. These intricate molds are the backbone of industries ranging from automotive to electronics, transforming raw metal sheets into precise components. Within this intricate landscape, Original Design Manufacturing (ODM) companies specializing in metal stamping dies emerge as unsung heroes, meeting the ever-evolving demands of the manufacturing world.

I. The Heart of Precision

At the core of metal stamping lies the die, a tool that embodies precision in its truest form. It’s responsible for creating intricate patterns, shapes, and features on metal sheets, consistently and flawlessly. ODM manufacturers specializing in metal stamping dies invest heavily in cutting-edge technology, computer-aided design (CAD) software, and skilled craftsmanship to ensure that their products meet the highest standards of quality and precision. II. Collaborative Design and Innovation ODM manufacturers thrive on collaboration. They work closely with their clients, listening to their specific requirements and challenges. This collaborative approach allows for the customization of metal stamping dies to suit the unique needs of each project. Whether it’s producing high-volume components for the automotive industry or intricate parts for consumer electronics, ODM manufacturers are up to the task. Moreover, these manufacturers are at the forefront of innovation, constantly exploring new materials and techniques to enhance the performance and durability of metal stamping dies. They push the boundaries of what’s possible, often introducing novel solutions that benefit multiple industries. III. Quality Assurance Quality control is a cornerstone of ODM metal stamping die manufacturers. They understand that even the slightest imperfection in a die can result in defects in the stamped metal parts, leading to costly rework and production delays. To ensure top-notch quality, they employ rigorous inspection processes, including computerized measurements, stress testing, and extensive quality assurance protocols. IV. Sustainable Manufacturing In today’s environmentally conscious world, sustainability is a key consideration in manufacturing processes. ODM manufacturers of metal stamping dies are not exempt from this responsibility. Many of these companies have embraced sustainable practices, using eco-friendly materials and energy-efficient processes. By reducing waste and energy consumption, they contribute to a greener, more sustainable future. V. Meeting Industry Challenges The manufacturing landscape is constantly evolving, and metal stamping die ODM manufacturers are poised to address emerging challenges. For instance, as the demand for lightweight materials in automotive and aerospace industries grows, these manufacturers are pioneering new methods for stamping aluminum and other lightweight alloys with precision. VI. Conclusion In the intricate world of metal stamping, ODM manufacturers of metal stamping dies are the unsung heroes, silently shaping industries with their precision, innovation, and commitment to quality. Their ability to collaborate, adapt, and push the boundaries of what’s possible ensures that they remain indispensable in the world of manufacturing. As the industry continues to evolve, we can rely on these ODM manufacturers to rise to the occasion, delivering the precision and efficiency that modern manufacturing demands.