Metal stamping, an essential process in the manufacturing industry, has played a pivotal role in shaping various everyday objects we often take for granted. At the heart of this intricate process lies the unsung hero: the metal stamping die. In this article, we delve into the world of metal stamping dies, uncovering their significance, types, and the craftsmanship behind their creation.

The Significance of Metal Stamping Dies

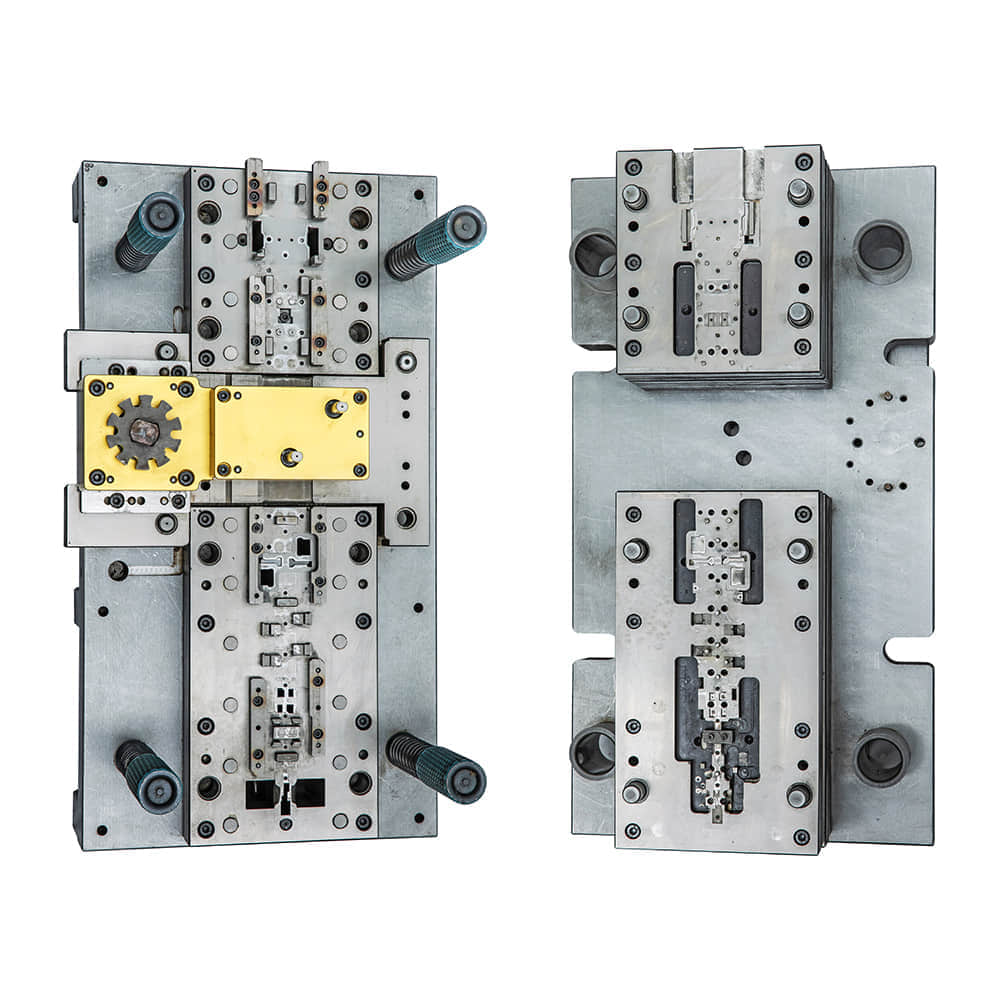

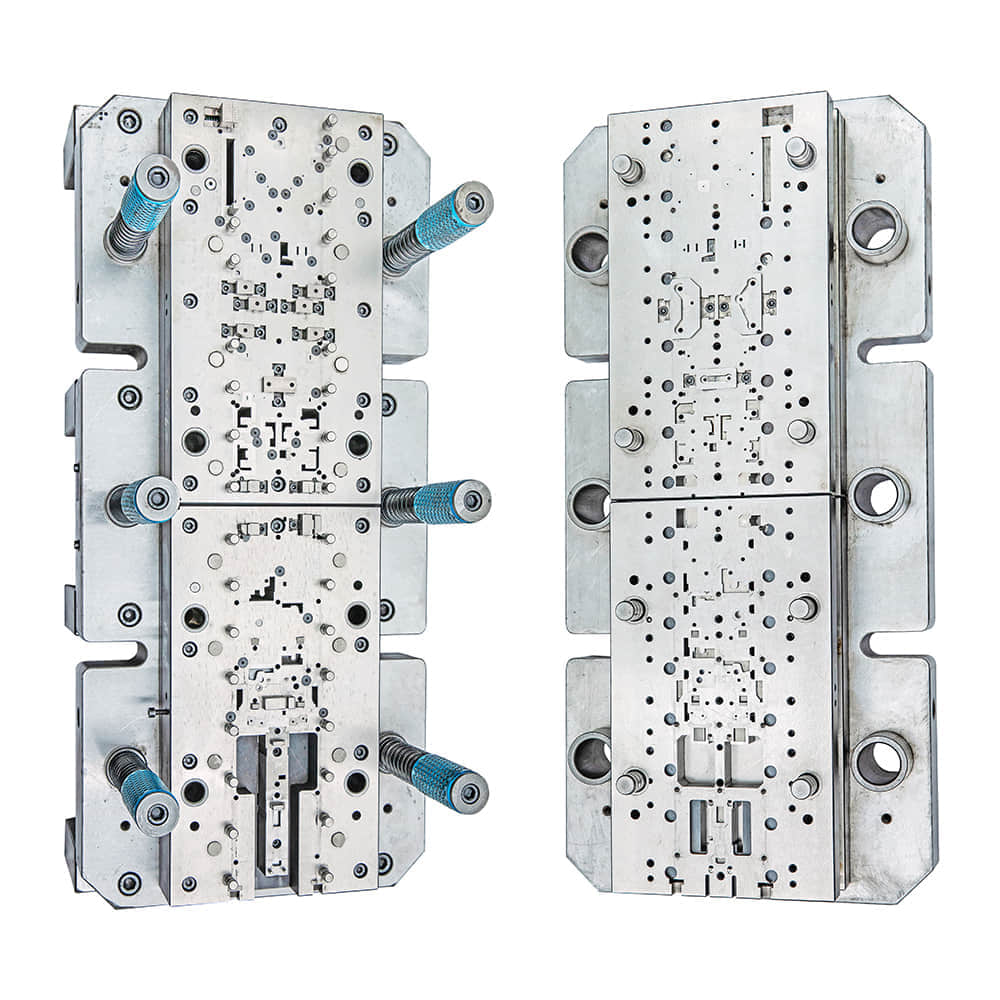

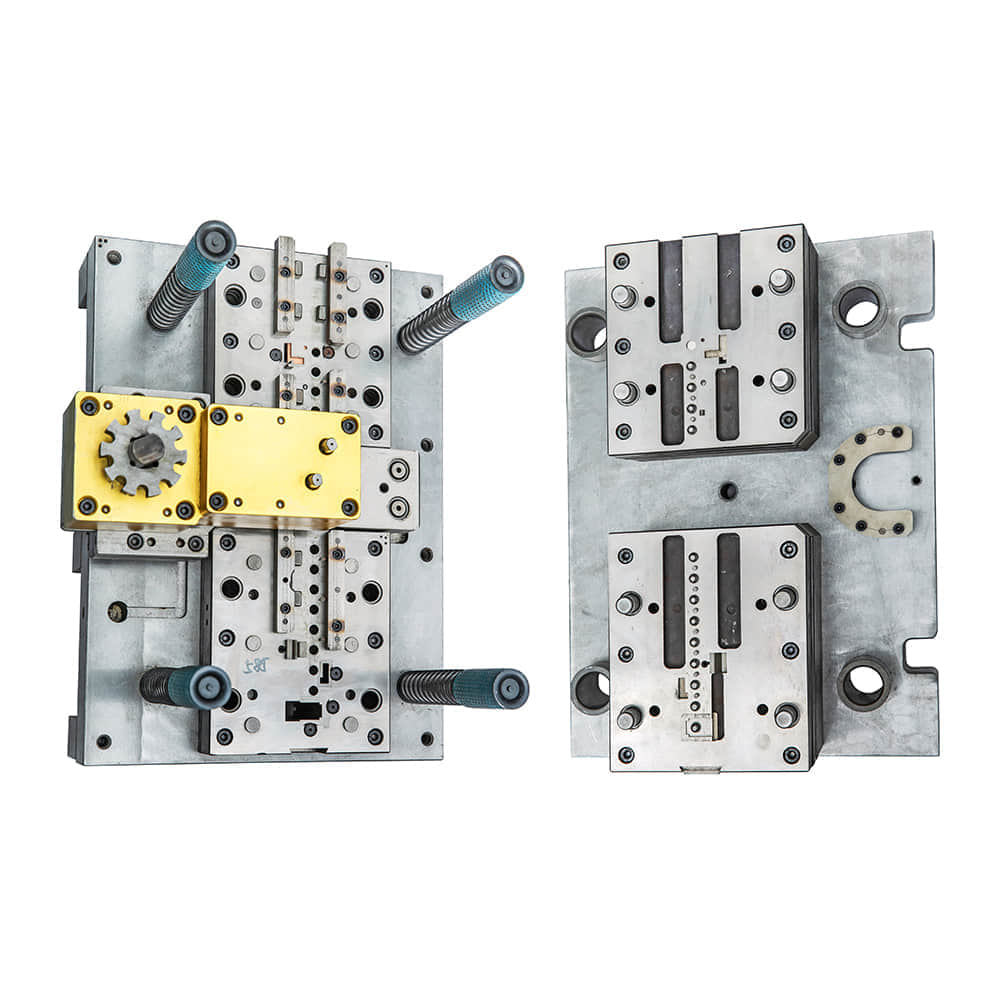

Metal stamping dies are molds used to shape, cut, or form metal sheets into precise shapes and sizes. Their significance extends far beyond their utilitarian purpose. They bridge the gap between imagination and reality, enabling manufacturers to transform raw materials into intricate components found in industries ranging from automotive to electronics. These dies ensure consistency in production, contributing to the reliability and quality of the final products. They are a testament to the marriage of art and engineering, as they require a deep understanding of material properties, mechanical principles, and creative design. Types of Metal Stamping Dies Metal stamping dies come in various types, each tailored to specific production needs. Progressive Dies:These dies consist of multiple stations that perform different operations as the metal sheet moves through them. Progressive dies are efficient for high-volume production of complex parts, as they can perform cutting, bending, and forming in a single pass. Transfer Dies:Similar to progressive dies, transfer dies also consist of multiple stations. However, in transfer dies, the metal sheet is moved from station to station using mechanical arms or other mechanisms. This allows for greater flexibility in handling larger and more intricate parts. Single-Station Dies:As the name suggests, these dies perform a single operation in a single station. They are often used for simpler operations or for prototyping new parts. Blanking Dies:These dies are designed specifically for cutting flat shapes out of sheet metal. They are commonly used in the initial stages of manufacturing, creating the basic outline of the part. Forming Dies:Forming dies are used to bend, stretch, or reshape metal sheets into desired shapes. They are crucial for producing three-dimensional parts. The Craftsmanship Behind the Creation Designing and manufacturing metal stamping dies requires a fusion of technical knowledge and artistic finesse. It starts with the design phase, where engineers and designers collaborate to create a blueprint for the die. Precision is paramount, as even a minor error can lead to defects in the final product. Once the design is finalized, skilled toolmakers take the reins. They meticulously craft the die components, often using advanced machining techniques such as computer numerical control (CNC) machining and electrical discharge machining (EDM). The level of detail in these components is astonishing, as they must perfectly replicate the desired part. Assembling the die is a delicate process that demands patience and expertise. The alignment of components, the calibration of moving parts, and the fine-tuning of clearances all contribute to the die’s overall functionality. The end result is not just a tool, but a work of art that embodies precision and purpose. Conclusion Metal stamping dies are the unsung champions behind the scenes of modern manufacturing. Their intricate designs, coupled with the craftsmanship and engineering skill that go into creating them, underscore their importance in shaping our world. From the simplest household items to complex automotive components, metal stamping dies silently revolutionize the way we produce goods. Understanding their significance and the meticulous process behind their creation allows us to appreciate the seamless integration of art and engineering that defines our industrial landscape.