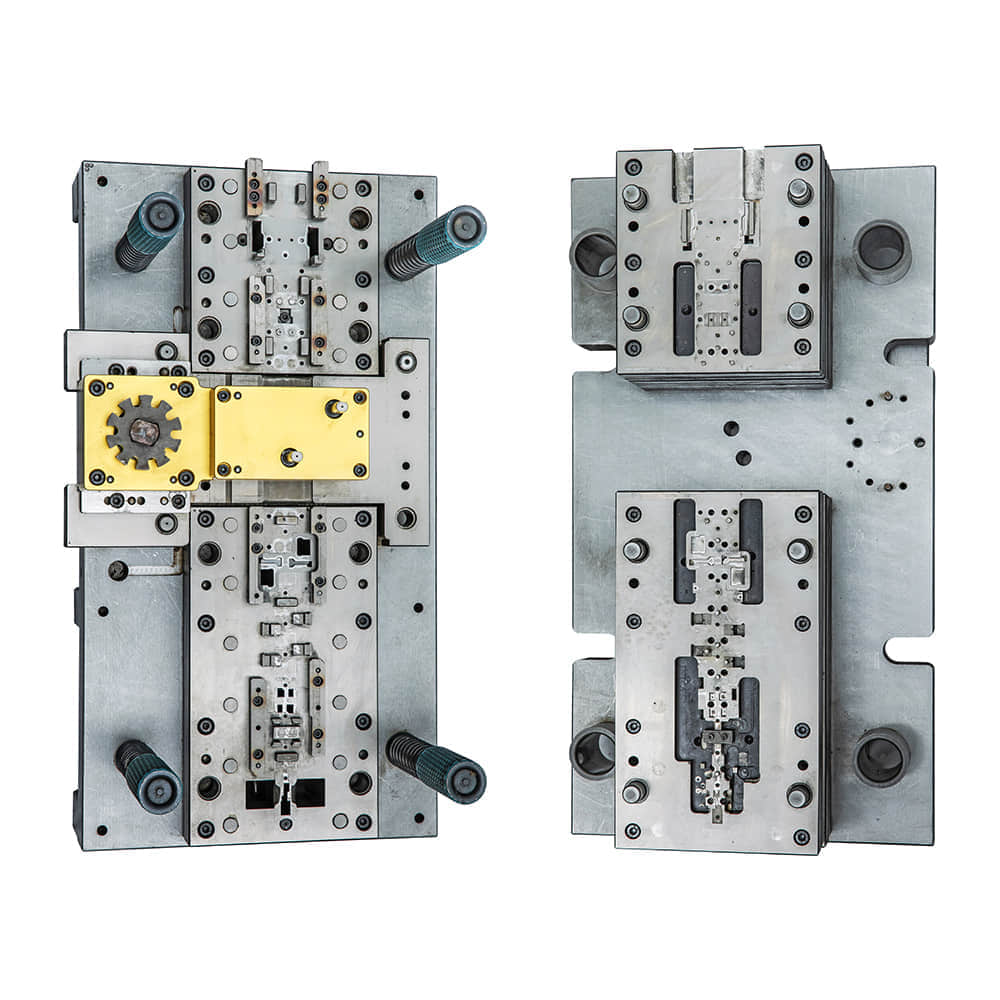

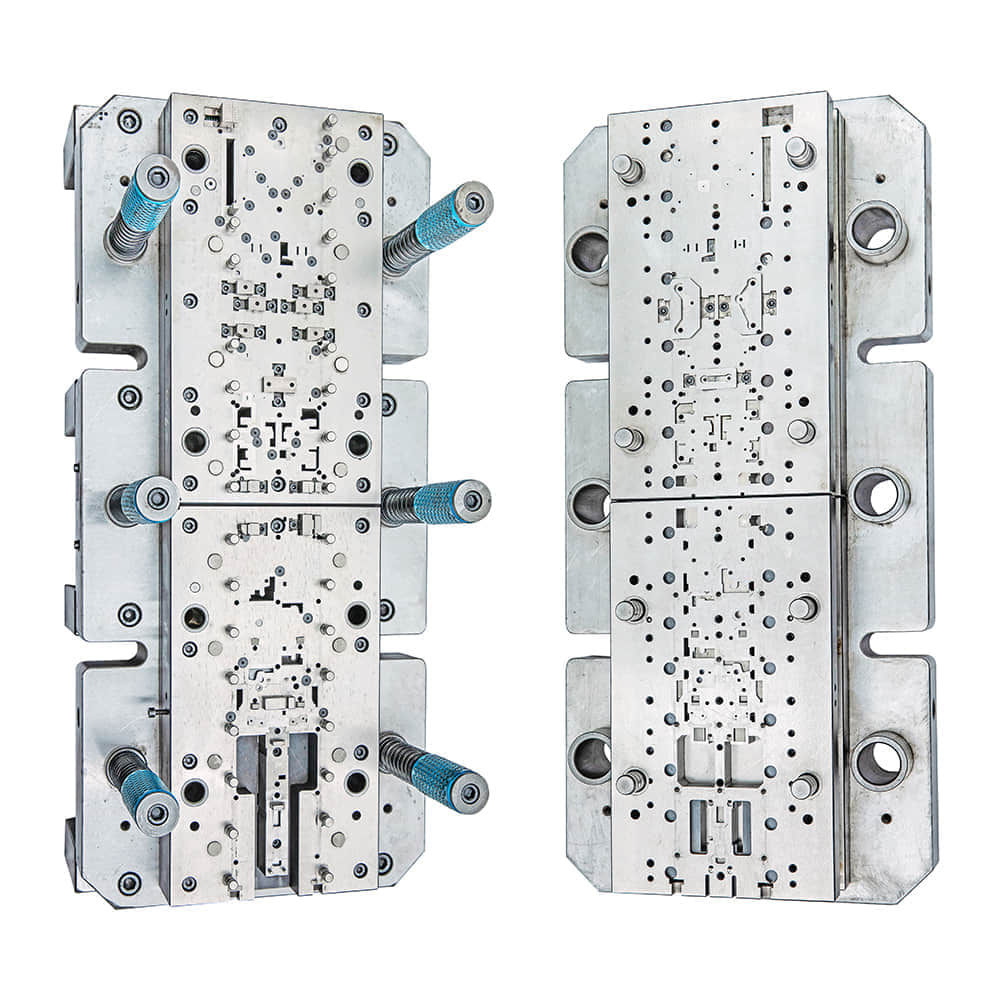

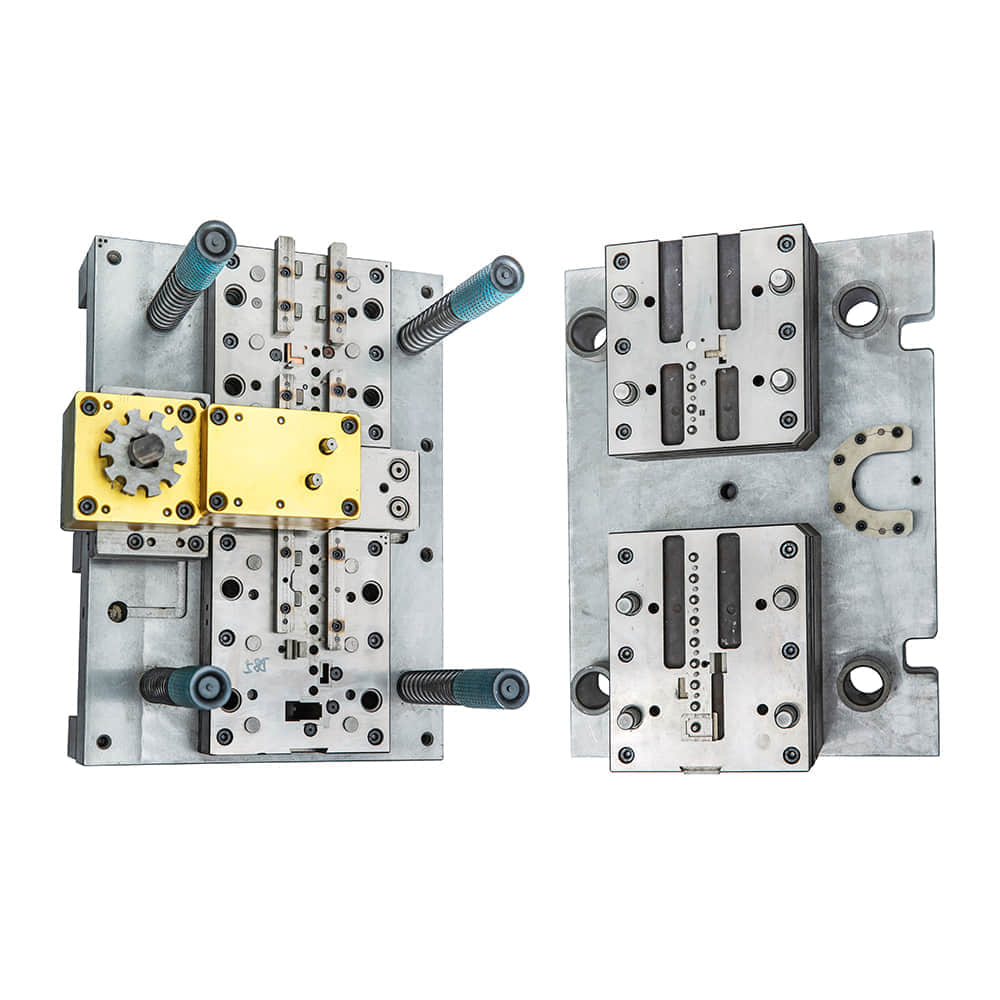

In the dynamic landscape of manufacturing, China has consistently emerged as a global leader, particularly in the realm of hardware mold production. The country’s hardware mold manufacturers have garnered attention and admiration for their exceptional craftsmanship, cutting-edge technology, and unwavering commitment to quality. This article delves into the world of China’s hardware mold manufacturers, shedding light on their prowess, innovation, and the factors driving their success.

Craftsmanship at its Finest

China’s hardware mold manufacturers are renowned for their impeccable craftsmanship. With a heritage steeped in traditional manufacturing techniques, these artisans have seamlessly blended time-honored skills with modern technology. This harmonious fusion allows them to produce molds with exquisite precision, intricate detailing, and superior functionality. Technological Innovation At the heart of China’s hardware mold manufacturing success lies an unwavering dedication to technological innovation. Manufacturers have embraced cutting-edge technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and precision CNC machining. These advancements not only enhance the accuracy and efficiency of mold production but also enable manufacturers to create complex and intricate designs that were once thought impossible. Quality First Quality is the cornerstone of China’s hardware mold manufacturing industry. Manufacturers adhere to stringent quality control processes at every stage of production. From material selection to mold design, testing, and final inspection, each step is meticulously executed to ensure the end product meets the highest international standards. This commitment to quality has earned these manufacturers a reputation for reliability and durability in their molds. Global Outreach China’s hardware mold manufacturers have transcended national borders, establishing themselves as key players in the global market. Their ability to offer competitive pricing without compromising quality has made them the preferred choice for businesses worldwide. This global outreach has not only boosted the Chinese manufacturing sector but has also contributed significantly to the country’s economic growth. Sustainability Efforts Recognizing the importance of sustainable manufacturing, China’s hardware mold manufacturers are increasingly adopting eco-friendly practices. From utilizing recyclable materials to implementing energy-efficient production processes, the industry is actively contributing to environmental conservation. These efforts not only underscore the manufacturers’ social responsibility but also position them as leaders in responsible manufacturing practices. Skilled Workforce The success of China’s hardware mold manufacturers can be attributed, in large part, to their skilled workforce. Manufacturers invest in training and development programs to ensure that their employees are well-versed in the latest technologies and techniques. This commitment to skill enhancement has not only elevated the quality of products but has also empowered workers with valuable expertise. Challenges and Opportunities Despite their remarkable achievements, China’s hardware mold manufacturers do face challenges. Intense global competition, rising labor costs, and the need to stay ahead in technological innovation are some of the hurdles they must navigate. However, these challenges are met with resilience and determination, propelling the industry to explore new avenues and seize emerging opportunities. In conclusion, China’s hardware mold manufacturers stand as exemplars of excellence in the manufacturing world. Their blend of traditional craftsmanship, technological innovation, and unwavering commitment to quality has propelled them to the forefront of global manufacturing. As they continue to evolve, these manufacturers are not only shaping the industry but also contributing to the narrative of China’s industrial prowess on the global stage.