Metal stamping is a pivotal manufacturing process utilized across various industries to create intricate and precise metal components. At the heart of this process lies the indispensable tool known as the metal stamping die. In this article, we delve into the world of metal stamping dies, uncovering their significance, types, and the technology that drives their evolution.

The Significance of Metal Stamping Dies

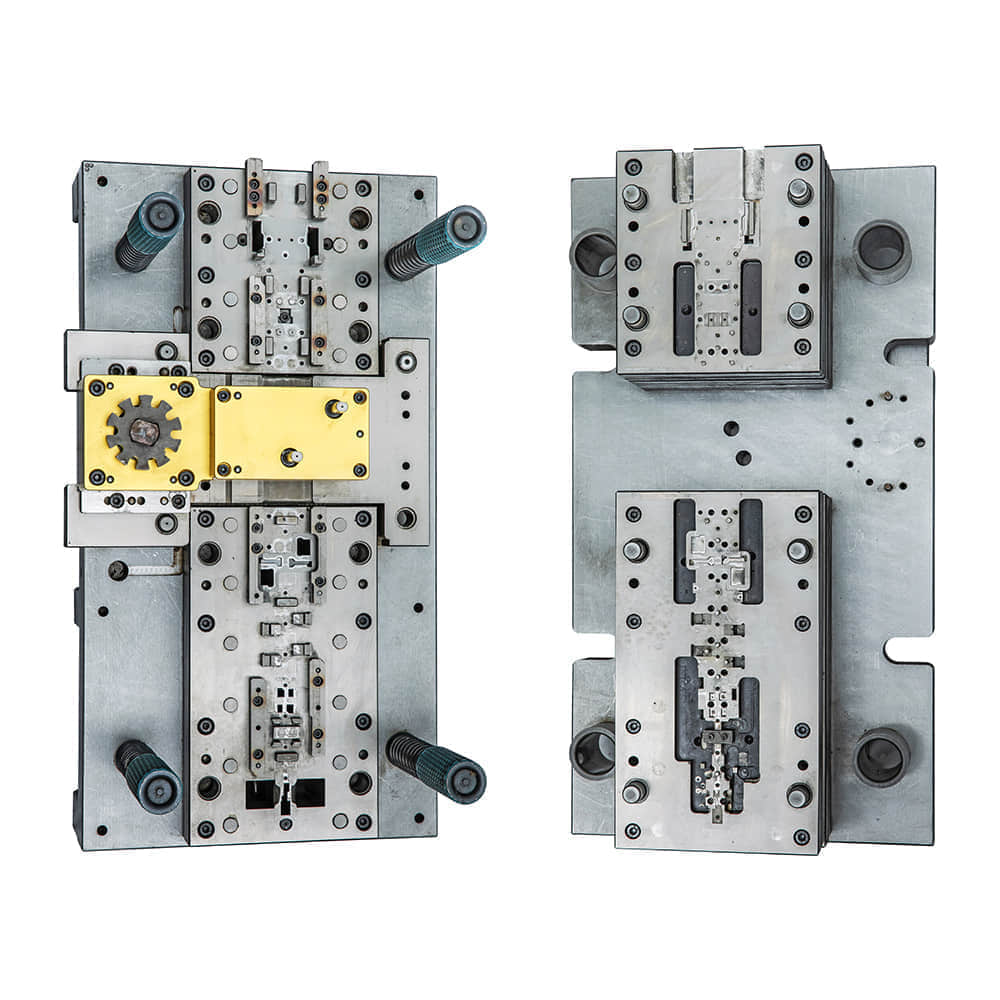

Metal stamping dies are instrumental in shaping raw metal materials into the desired forms. They serve as molds that enable mass production of consistent, high-quality components, ranging from automotive parts to household appliances. This process involves the application of extreme pressure to cut or shape metal sheets, resulting in products with tight tolerances and intricate designs. Types of Metal Stamping Dies Metal stamping dies can be broadly categorized into several types based on their functions: Blanking Dies:These dies are used to cut flat pieces of material into specific shapes. They are commonly employed to create components like washers and discs. Piercing Dies:Piercing dies are designed to create holes in metal sheets. They are widely used in industries such as aerospace and electronics for manufacturing parts like brackets and connectors. Forming Dies:Forming dies bend and reshape metal materials to achieve specific contours. The automotive industry extensively relies on forming dies to produce car body panels with intricate curves and shapes. Drawing Dies:Drawing dies are specialized in creating hollow shapes from sheet metal. They are commonly used in the production of cylindrical or cup-like components. Progressive Dies:These complex dies perform multiple operations in a sequential manner. They are ideal for high-volume production runs, enabling the creation of several features in a single pass. Evolution and Technology The evolution of metal stamping dies is closely intertwined with advancements in technology. Traditional dies were often crafted by skilled artisans through labor-intensive processes. However, modern manufacturing has embraced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to enhance precision and efficiency. CAD:CAD software allows engineers to design intricate die shapes with unprecedented accuracy. Three-dimensional modeling enables the visualization of the final product, making it easier to identify potential design flaws before the manufacturing process begins. CAM:CAM software takes CAD designs and translates them into precise machine instructions. This automation streamlines the manufacturing process, reducing errors and minimizing the need for manual intervention. Simulation:Simulation software plays a crucial role in the development of metal stamping dies. Engineers can simulate the stamping process virtually, analyzing factors like material flow, stress distribution, and potential defects. This minimizes the need for costly trial-and-error iterations. Materials and Coatings:The materials used to create metal stamping dies have also evolved. High-speed tool steels, carbides, and even ceramic materials are now employed to enhance durability and longevity. Additionally, advanced coatings like titanium nitride and diamond-like carbon are applied to reduce friction and wear. Conclusion Metal stamping dies stand as the unsung heroes of modern manufacturing. Their ability to transform raw metal sheets into intricate components with speed, precision, and consistency is a testament to the advancements in technology and engineering. As industries continue to demand higher quality and efficiency, the evolution of metal stamping dies remains an ongoing journey of innovation and excellence.