In the realm of modern manufacturing, metal stamping has emerged as a pivotal process that facilitates the creation of intricate metal parts used in various industries. At the heart of this process lies the metal stamping parts manufacturer, a key player responsible for producing components that range from the mundane to the highly specialized. This article delves into the world of metal stamping manufacturers, shedding light on their significance, processes, and the impact they have on diverse sectors.

The Essence of Metal Stamping Parts Manufacturers

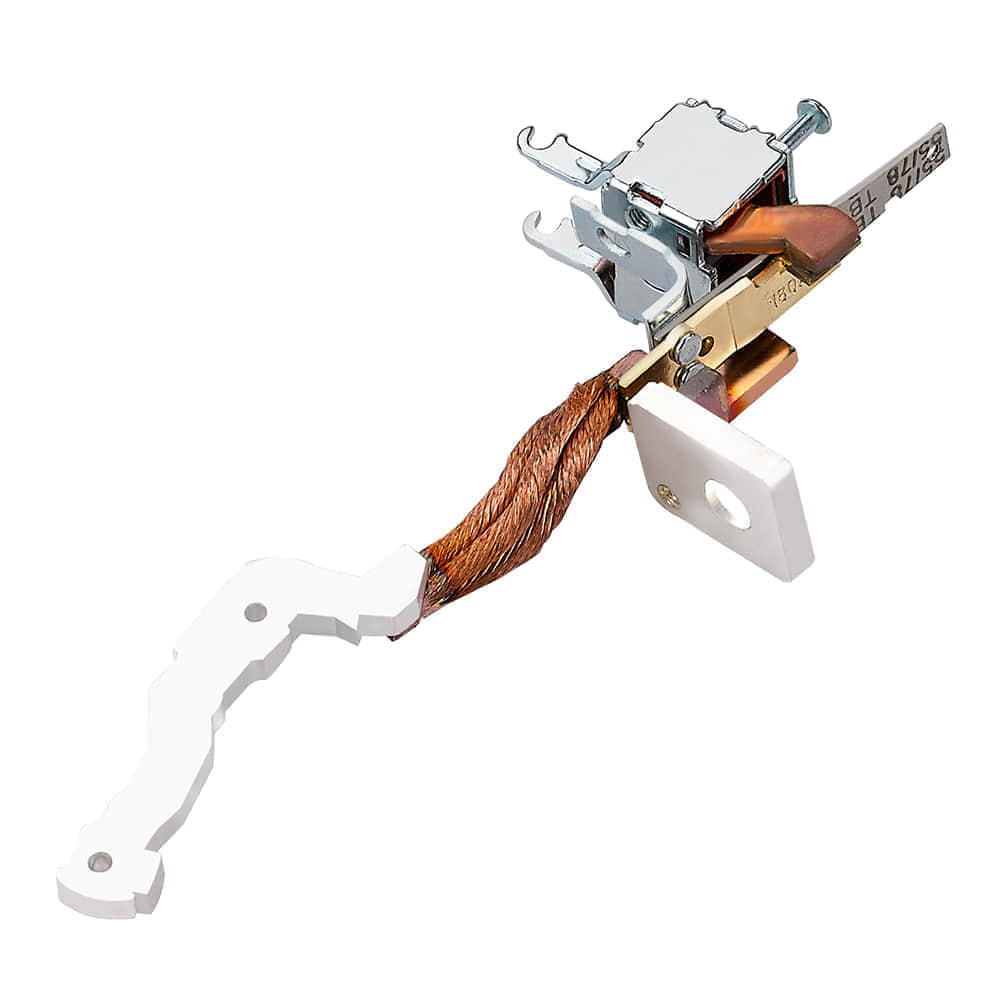

Metal stamping parts manufacturers are industrial entities specializing in the production of components through the process of metal stamping. Metal stamping, often referred to as pressing, involves using a die and a press to transform flat metal sheets into the desired shapes. This technique is employed to create a wide spectrum of products, including automotive parts, electronics enclosures, aerospace components, household appliances, and more. The versatility of metal stamping makes it a cornerstone of modern manufacturing. The Process Unveiled The process commences with the design and creation of a custom die, which determines the final shape of the metal part. This die is often crafted with extreme precision, as even a minor flaw can lead to defective parts. Once the die is ready, it is installed into a press, and metal sheets are fed into the machinery. The press exerts immense force, causing the metal to be shaped according to the die’s specifications. The resultant parts then undergo finishing processes, such as deburring, cleaning, and coating, to ensure they meet quality standards. Precision and Innovation Precision is the cornerstone of metal stamping. Manufacturers must adhere to tight tolerances, ensuring that each produced part conforms to exact specifications. This emphasis on precision is driven by the industries that rely on these components. For instance, the automotive sector demands consistent and accurate parts to ensure safety and performance. Beyond precision, innovation also plays a crucial role. Manufacturers are constantly seeking new ways to enhance their processes, whether through advanced die designs, better materials, or streamlined production techniques. Role in Various Industries Metal stamping parts manufacturers cater to a plethora of industries, each with its unique requirements. In the automotive field, they provide everything from engine and transmission components to intricate brake system parts. The electronics sector benefits from metal stamping through the creation of casings, connectors, and heat sinks. Aerospace relies on these manufacturers for lightweight yet sturdy components that contribute to aircraft performance. Even seemingly unrelated domains like healthcare utilize metal stamping for medical device manufacturing. The role of these manufacturers is pervasive, underscoring their importance in modern society. Challenges and Future Outlook The world of metal stamping isn’t without its challenges. Manufacturers must navigate fluctuating material costs, evolving design specifications, and the need for sustainable practices. Moreover, as industries adopt more complex and innovative designs, manufacturers must adapt to produce intricate parts with uncompromised quality. The future holds the promise of technological advancements that could further refine the metal stamping process. From enhanced automation and robotics to more sustainable materials, the industry is poised for transformation. In Conclusion Metal stamping parts manufacturers serve as the backbone of many industries, playing a pivotal role in producing the components that make modern life possible. Their intricate processes, commitment to precision, and adaptability make them indispensable partners for various sectors. As technology continues to evolve, so will the methods and techniques employed by these manufacturers, ensuring that they remain at the forefront of innovation and production.