In the intricate realm of modern manufacturing, metal stamping has emerged as a cornerstone process. This process, which involves the transformation of sheet metal into various shapes and sizes, is executed by skilled artisans known as metal stamping parts manufacturers. In this article, we will delve into the fascinating world of these manufacturers, exploring their significance, techniques, and impact on diverse industries.

The Significance of Metal Stamping Parts Manufacturers

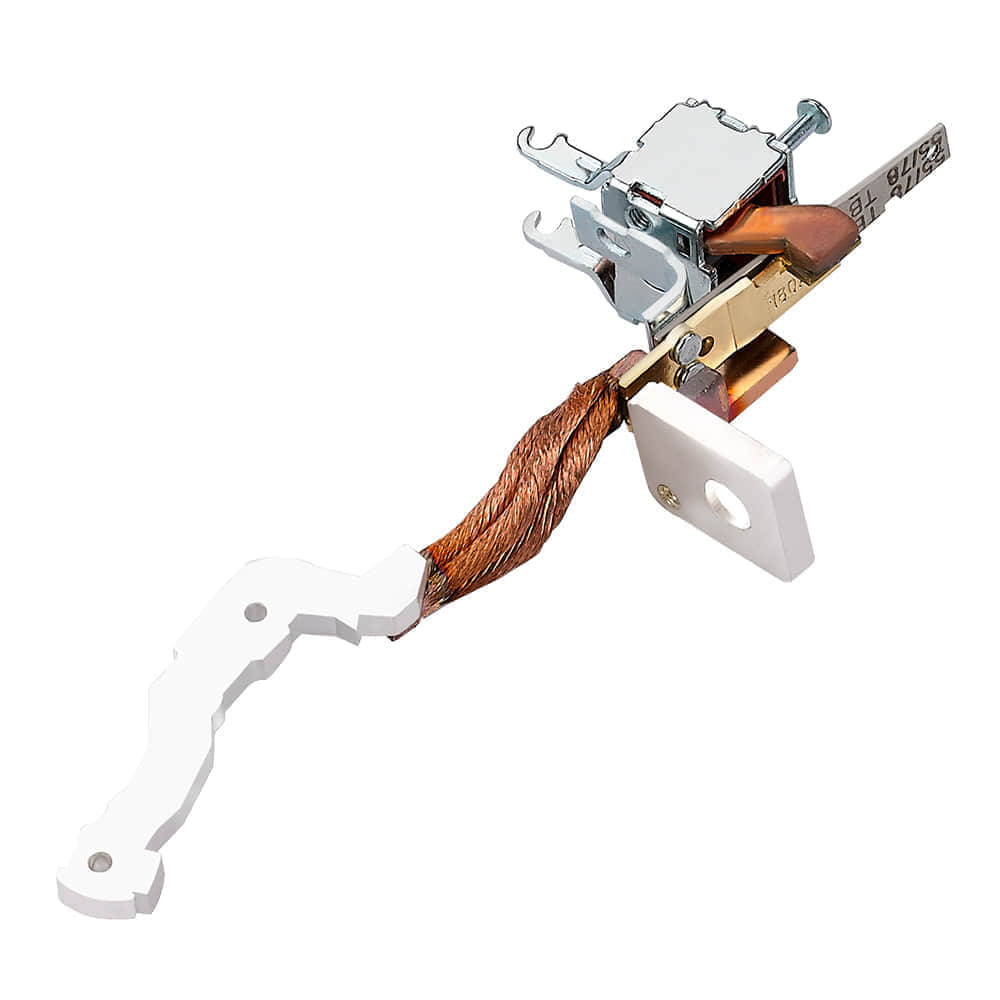

Metal stamping is a manufacturing process that has revolutionized the way intricate metal parts are fabricated. From the automotive industry to electronics, appliances, and beyond, metal stamping parts manufacturers play a pivotal role in shaping diverse products. Their ability to craft high-precision components with consistency and efficiency has elevated the standards of modern manufacturing. These manufacturers are equipped with a profound understanding of materials, tools, and techniques. Their expertise allows them to create intricate parts that meet stringent quality standards while optimizing production costs. This balance between precision and efficiency makes metal stamping a preferred choice for industries seeking both quality and quantity. Techniques Employed by Metal Stamping Parts Manufacturers Metal stamping involves a series of intricate processes, each demanding skill and attention to detail. Blank creation, bending, embossing, flanging, and coining are just a few of the techniques employed by these manufacturers. The process begins with the creation of a metal blank, which is then shaped and manipulated using specialized tools and dies. The precision of these tools is a testament to the craftsmanship of the manufacturers. One of the key advantages of metal stamping is its ability to maintain consistency over large production runs. The use of automated presses, robotic arms, and computer-aided design (CAD) software allows manufacturers to replicate designs with unparalleled accuracy. This consistency is a driving factor behind the success of metal stamping in industries where uniformity and precision are paramount. Impact on Industries and Innovation Metal stamping parts manufacturers contribute significantly to various industries, driving innovation and progress. In the automotive sector, they fabricate components ranging from simple brackets to complex transmission parts. The electronics industry relies on their expertise to create intricate parts for devices such as smartphones, laptops, and home appliances. Moreover, aerospace and medical equipment manufacturers also benefit from the precision and reliability that metal stamping offers. Furthermore, the collaboration between designers, engineers, and metal stamping parts manufacturers often leads to innovative solutions. The malleability of metal, coupled with the expertise of these manufacturers, opens doors to new design possibilities that were once deemed unattainable. As industries continue to evolve, these manufacturers find themselves at the forefront of turning imaginative concepts into tangible realities. Challenges and Future Prospects Despite the advancements in technology, metal stamping parts manufacturing is not without its challenges. The complexity of certain designs, the need for continuous process refinement, and the demand for sustainable practices are all factors that manufacturers must navigate. Striking a balance between tradition and innovation remains a constant endeavor. Looking ahead, the future of metal stamping parts manufacturing appears promising. As industries demand smaller, lighter, and more intricate components, the expertise of these manufacturers will become even more critical. Additionally, the integration of AI, automation, and sustainable practices will likely reshape the landscape, offering new avenues for growth and efficiency. In Conclusion Metal stamping parts manufacturers are the unsung heroes of modern manufacturing, shaping industries and products that touch our lives daily. Their craftsmanship, precision, and ability to adapt to evolving technologies make them indispensable contributors to progress. As we continue to push the boundaries of innovation, let us not forget the skilled artisans behind the scenes, turning sheets of metal into the building blocks of our modern world.