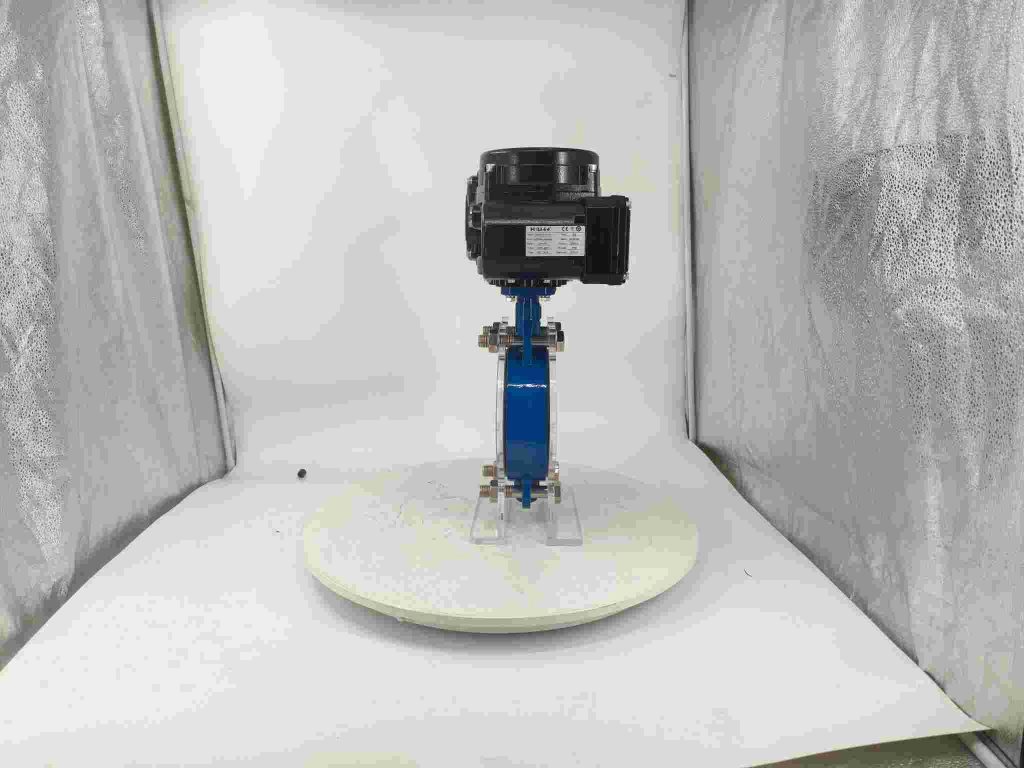

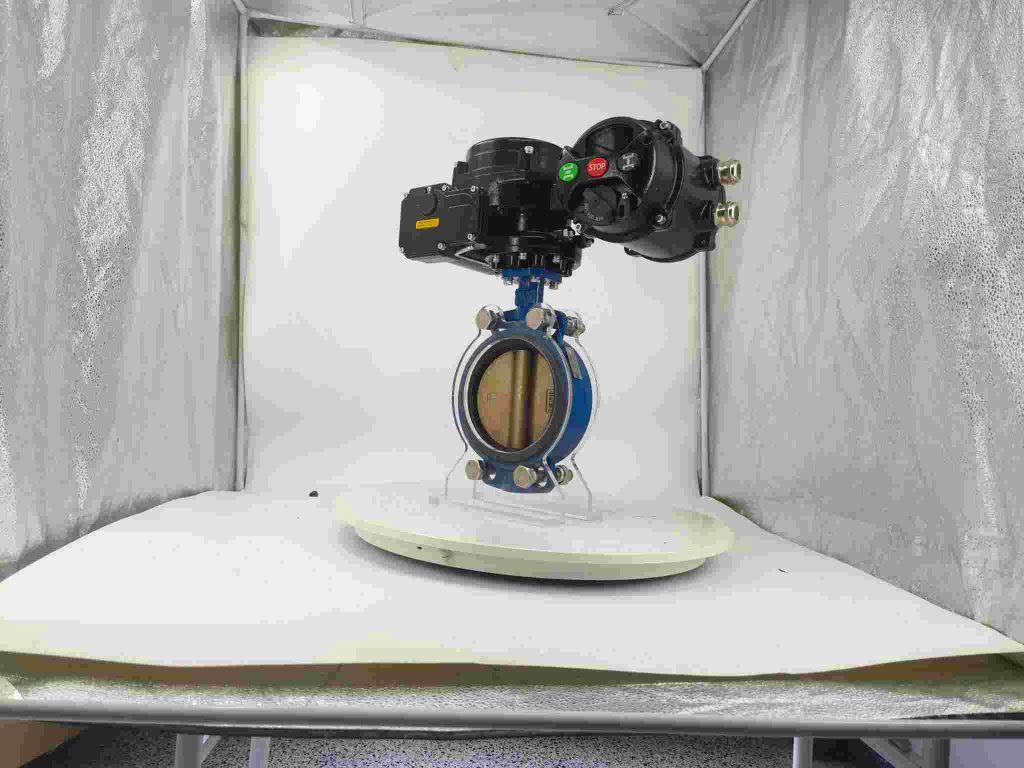

In today’s industrial world, ensuring safety in hazardous environments is a top priority. One of the crucial components that contribute to this safety is the Explosion-proof electric butterfly valve. Designed to handle the most demanding conditions, this specialized valve serves an essential role in controlling the flow of liquids or gases while preventing any risk of explosion in areas where volatile substances are present. This article will explore the significance, applications, and advantages of Explosion-proof electric butterfly valves in industrial settings.

What is an Explosion-proof Electric Butterfly Valve?

An Explosion-proof electric butterfly valve is a type of valve that combines the functionality of a traditional butterfly valve with explosion-proof technology. A butterfly valve is a quarter-turn valve used to regulate the flow of fluids within a pipeline. Its simple design features a circular disc that rotates to either open or close the valve. When combined with an electric actuator, the valve can be operated remotely, offering ease of control and automation. The term “explosion-proof” refers to the design of the valve and actuator, which are built to withstand high-pressure environments and prevent sparks, electrical faults, or any other potential ignition sources from igniting flammable gases, vapors, or dust present in the surrounding atmosphere. This makes Explosion-proof electric butterfly valves indispensable in industries such as oil and gas, chemical processing, mining, and pharmaceuticals.