In the realm of manufacturing, injection molding plays a pivotal role in the production of countless everyday items, from intricate electronic components to household appliances and automotive parts. Behind the scenes of this essential process stands the injection mold manufacturer, a key player in the world of manufacturing. In this article, we will delve into the world of injection mold manufacturers, exploring their critical role, the innovation they bring to the table, and the unwavering commitment to quality that defines their work.

The Crucial Role of Injection Mold Manufacturers

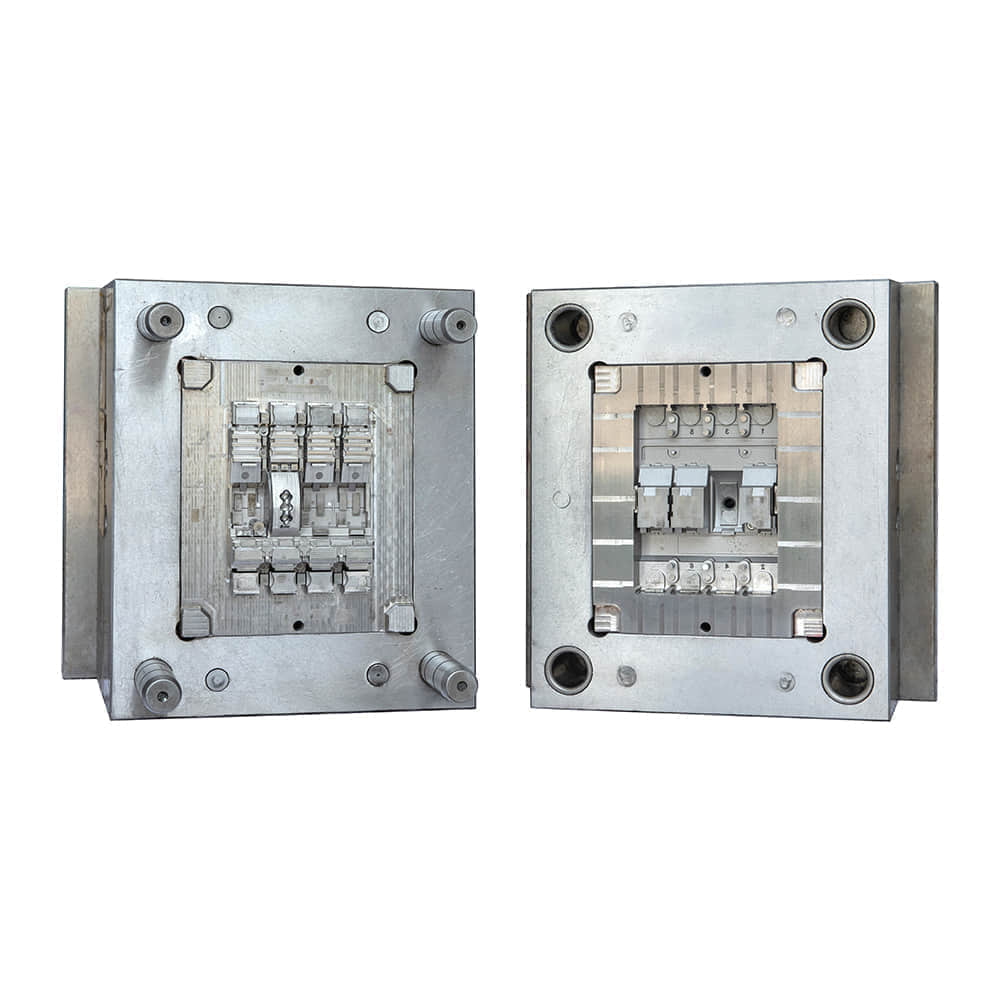

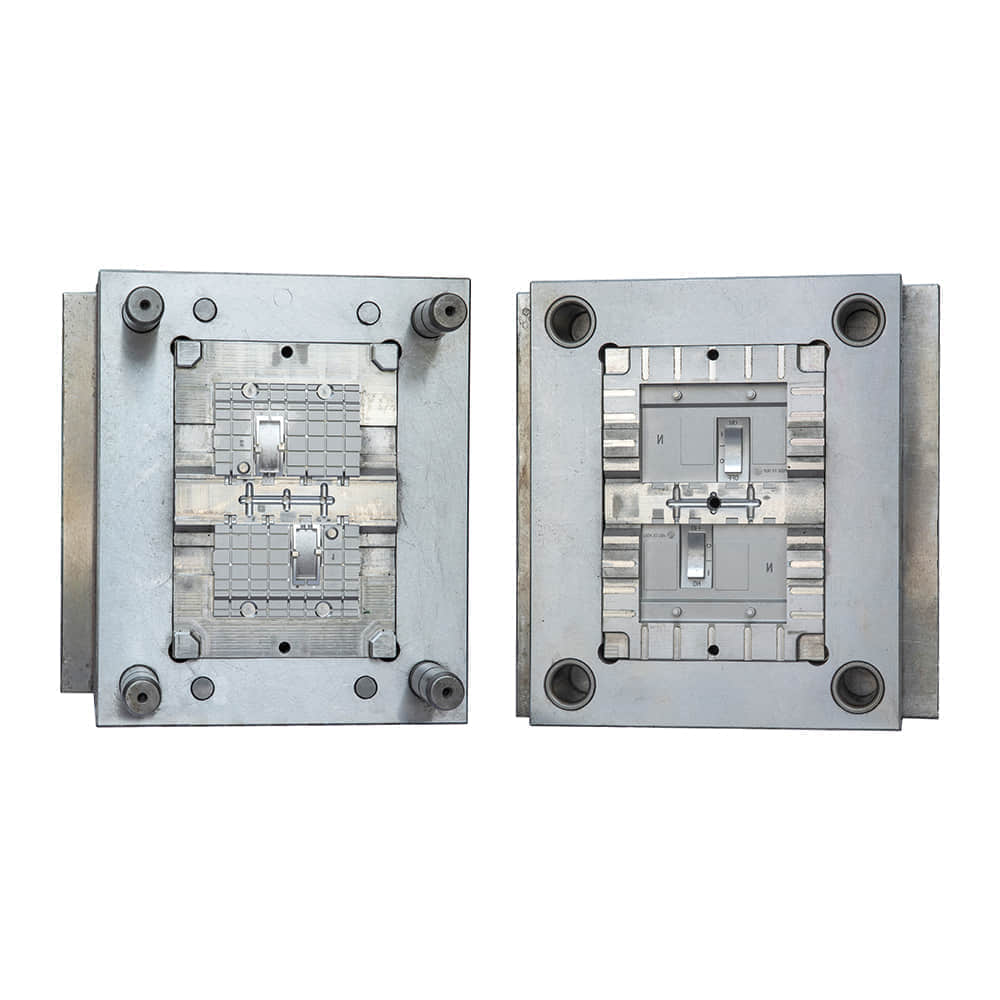

Injection mold manufacturers are the masterminds behind the molds that shape plastics and other materials into various products. These molds are the heart of the injection molding process, determining the quality, precision, and efficiency of production. The significance of injection mold manufacturers cannot be overstated, as they serve as the foundation upon which entire industries rely. Precision Engineering at Its Best One of the hallmarks of injection mold manufacturers is their dedication to precision engineering. The molds they create must meet exacting standards to produce parts that fit seamlessly together in final products. Achieving such precision requires cutting-edge technology, vast expertise, and an acute attention to detail. In modern manufacturing, computer-aided design (CAD) and computer-aided manufacturing (CAM) software play pivotal roles in mold design and production. These tools enable injection mold manufacturers to create intricate designs with micron-level accuracy. From tiny medical device components to large automotive parts, these manufacturers can customize molds to meet the unique requirements of their clients. Innovation in Material and Design Injection mold manufacturers are at the forefront of innovation in materials and design. They constantly explore new materials that offer enhanced performance, durability, and sustainability. Biodegradable plastics, high-strength composites, and specialized polymers are just a few examples of materials that have revolutionized the manufacturing industry. These innovations wouldn’t be possible without the expertise of injection mold manufacturers. Moreover, injection mold manufacturers are adept at developing molds for complex and innovative product designs. They collaborate closely with product designers and engineers to ensure that molds are optimized for the intended application. Whether it’s creating intricate patterns on consumer electronics or ensuring a watertight seal in plumbing components, injection mold manufacturers are indispensable partners in bringing creative ideas to life. Quality Assurance and Certifications Quality is the cornerstone of any successful manufacturing process, and injection mold manufacturers take this responsibility seriously. They adhere to rigorous quality assurance standards and certifications to ensure that every mold they produce meets or exceeds industry requirements. ISO 9001 certification, for instance, is a common benchmark for quality management systems in the manufacturing sector. Injection mold manufacturers with this certification demonstrate their commitment to consistently delivering products that meet customer expectations. Environmental Responsibility In recent years, environmental concerns have taken center stage in manufacturing. Injection mold manufacturers are actively involved in sustainable practices, aiming to minimize waste and reduce their carbon footprint. They explore eco-friendly materials, implement energy-efficient processes, and embrace recycling and waste reduction strategies. In conclusion, injection mold manufacturers are unsung heroes of the manufacturing world, playing a vital role in shaping the products that we use daily. Their dedication to precision, innovation, quality, and sustainability ensures that our world continues to progress technologically while minimizing its impact on the environment. As technology advances and new materials emerge, injection mold manufacturers will remain at the forefront of innovation, driving progress and shaping the future of manufacturing.