Injection molded parts have become an integral component of various industries, ranging from automotive to consumer electronics. The driving force behind the production of these intricate components is none other than injection molded parts manufacturers. In this article, we delve into the world of injection molding, exploring the crucial role played by manufacturers in delivering precision and innovation to meet the demands of modern manufacturing.

The Art of Injection Molding

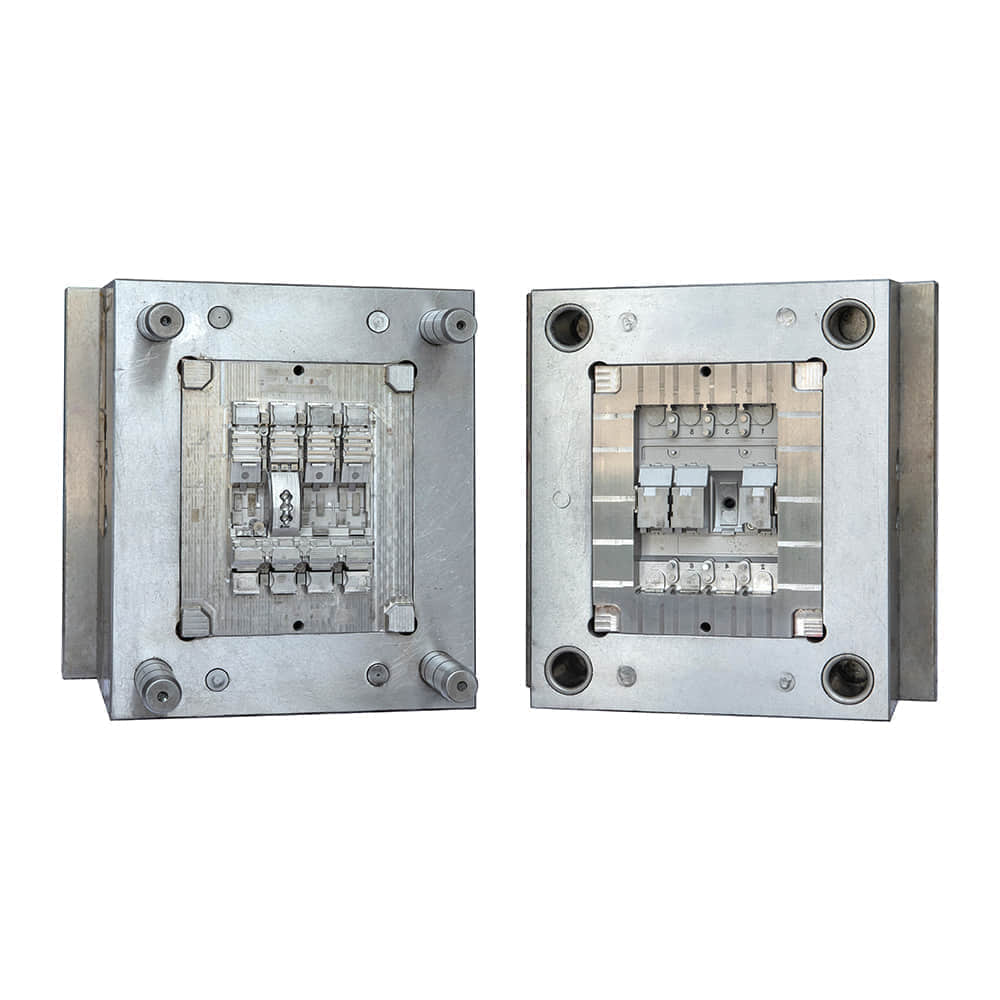

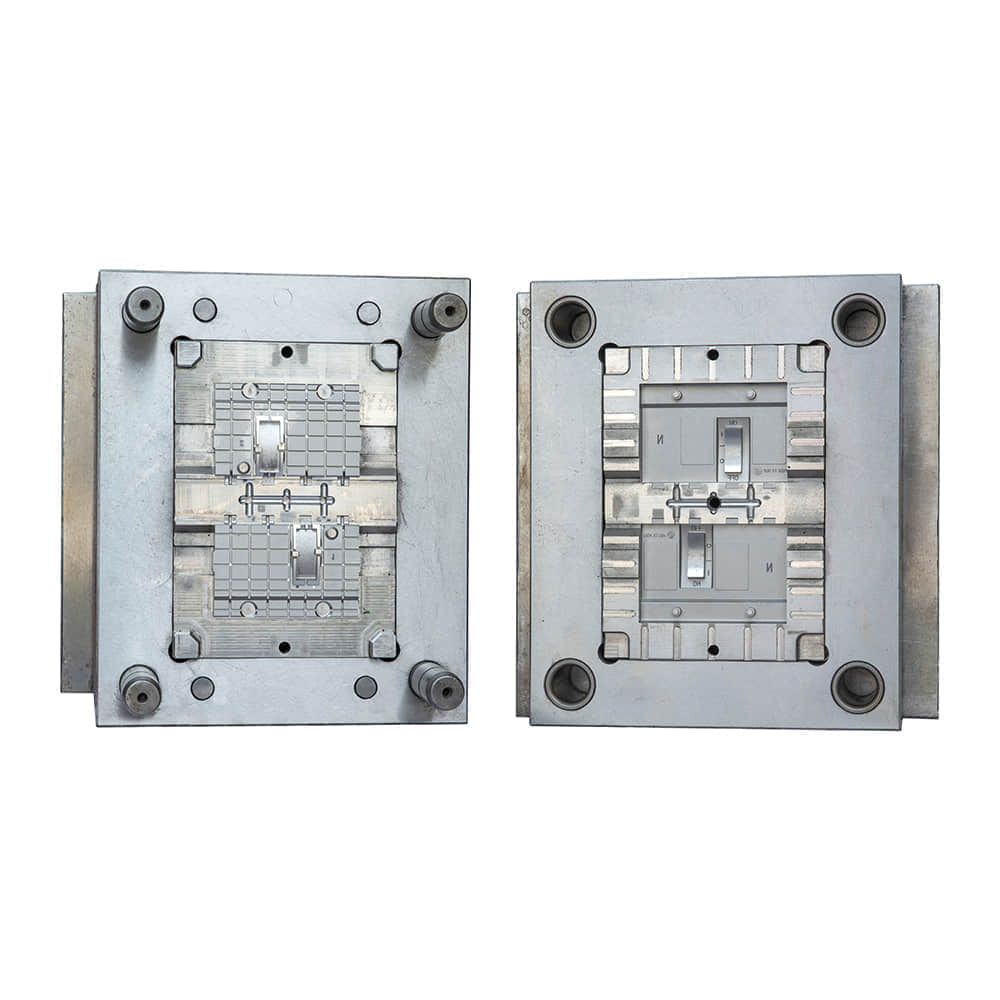

Injection molding is a manufacturing process that involves melting a chosen material, typically a thermoplastic or thermosetting polymer, and injecting it into a mold cavity. Once the material cools and solidifies, the mold is opened to reveal a precisely shaped part. The process is renowned for its efficiency, precision, and versatility, making it a preferred choice for producing intricate components. The Vital Role of Injection Molded Parts Manufacturers Injection molded parts manufacturers are the backbone of this industry. They are responsible for translating design concepts into tangible products. Let’s explore some key aspects of their pivotal role: Design Expertise: Manufacturers collaborate closely with designers and engineers to transform concepts into moldable designs. Their expertise ensures that the final product meets the required specifications, including strength, durability, and aesthetic appeal. Material Selection: Choosing the right material is paramount in injection molding. Manufacturers have a deep understanding of various materials’ properties, enabling them to select the most suitable one for the intended application, whether it’s for the automotive, medical, or consumer goods sector. Mold Design and Fabrication: The heart of injection molding lies in the mold itself. Manufacturers meticulously design and fabricate molds to meet exacting standards. This includes considerations for complex geometries, multiple cavities, and efficient cooling systems. Precision Manufacturing: Injection molded parts manufacturers operate state-of-the-art injection molding machines that precisely control factors such as temperature, pressure, and injection speed. This precision is essential in achieving consistent part quality. Quality Assurance: Rigorous quality control measures are implemented throughout the manufacturing process. Manufacturers conduct regular inspections, perform dimensional checks, and ensure that parts meet all specified tolerances and standards. Innovation and Research: Staying at the forefront of technology is crucial. Manufacturers invest in research and development to explore new materials, processes, and manufacturing techniques. This drive for innovation leads to improved product performance and cost-effectiveness. Meeting the Demands of Modern Manufacturing Modern manufacturing demands not only precision but also agility and sustainability. Injection molded parts manufacturers rise to the challenge in several ways: Customization: Manufacturers can produce highly customized parts, accommodating the unique requirements of each industry. This flexibility is crucial for industries with diverse needs. Efficiency: Injection molding is known for its minimal material wastage, making it an environmentally friendly choice. Manufacturers continually refine their processes to reduce energy consumption and waste. Short Lead Times: Manufacturers are adept at quick turnaround times, allowing companies to respond swiftly to market demands. This is particularly important in industries where time-to-market is a critical factor. Cost-Effective Production: The efficiency of injection molding, combined with manufacturers’ expertise, leads to cost-effective production. This enables businesses to remain competitive in their respective markets. Conclusion Injection molded parts manufacturers are the unsung heroes of modern manufacturing. Their expertise, precision, and commitment to innovation drive the production of intricate components that are essential in various industries. From designing molds to selecting materials and ensuring quality, manufacturers play a pivotal role in delivering precision and innovation to meet the demands of contemporary manufacturing. As technology continues to evolve, these manufacturers will undoubtedly continue to push the boundaries of what is possible in the world of injection molding.