Injection Molded Parts Manufacturer: A Catalyst for Innovation

In the realm of modern manufacturing, injection molded parts have emerged as a driving force behind countless industries. These versatile components find their applications in everything from consumer electronics to automotive engineering, revolutionizing the way products are designed, produced, and delivered. At the core of this manufacturing revolution stand injection molded parts manufacturers, whose expertise and innovation have played a pivotal role in shaping the world as we know it today.

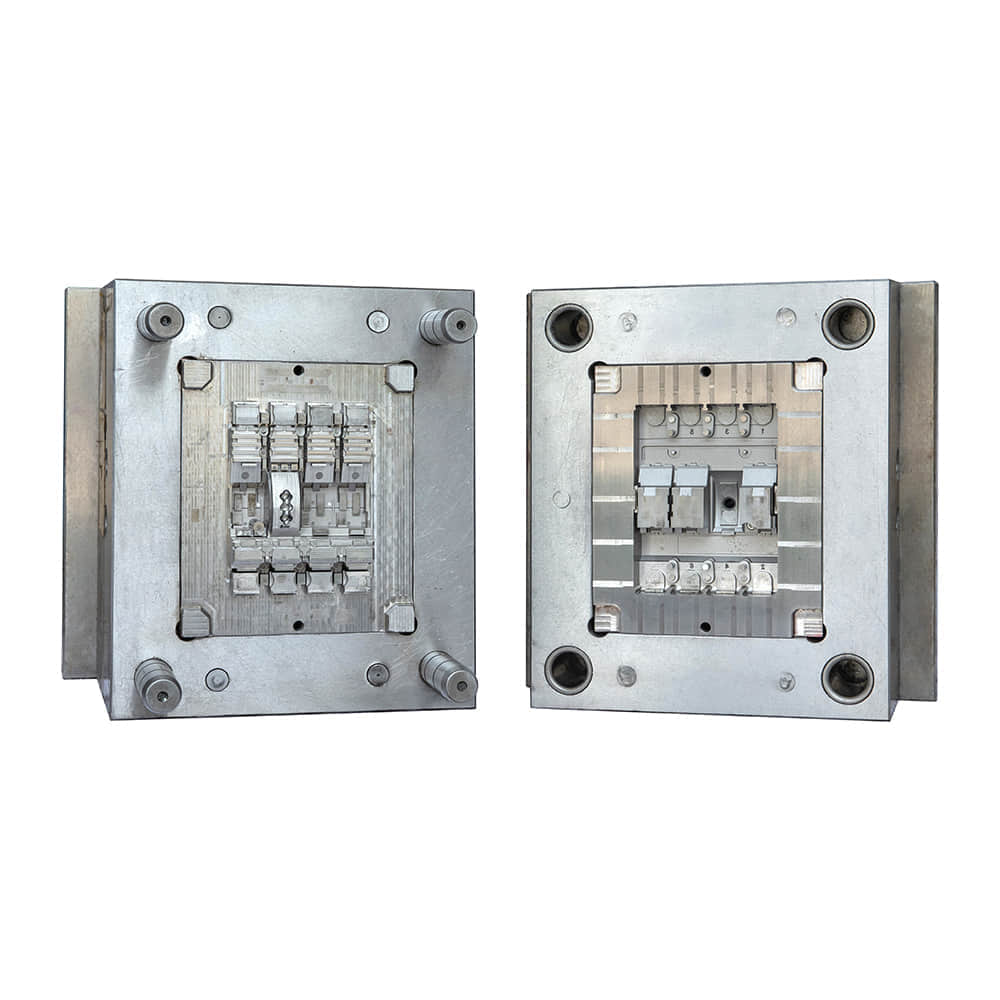

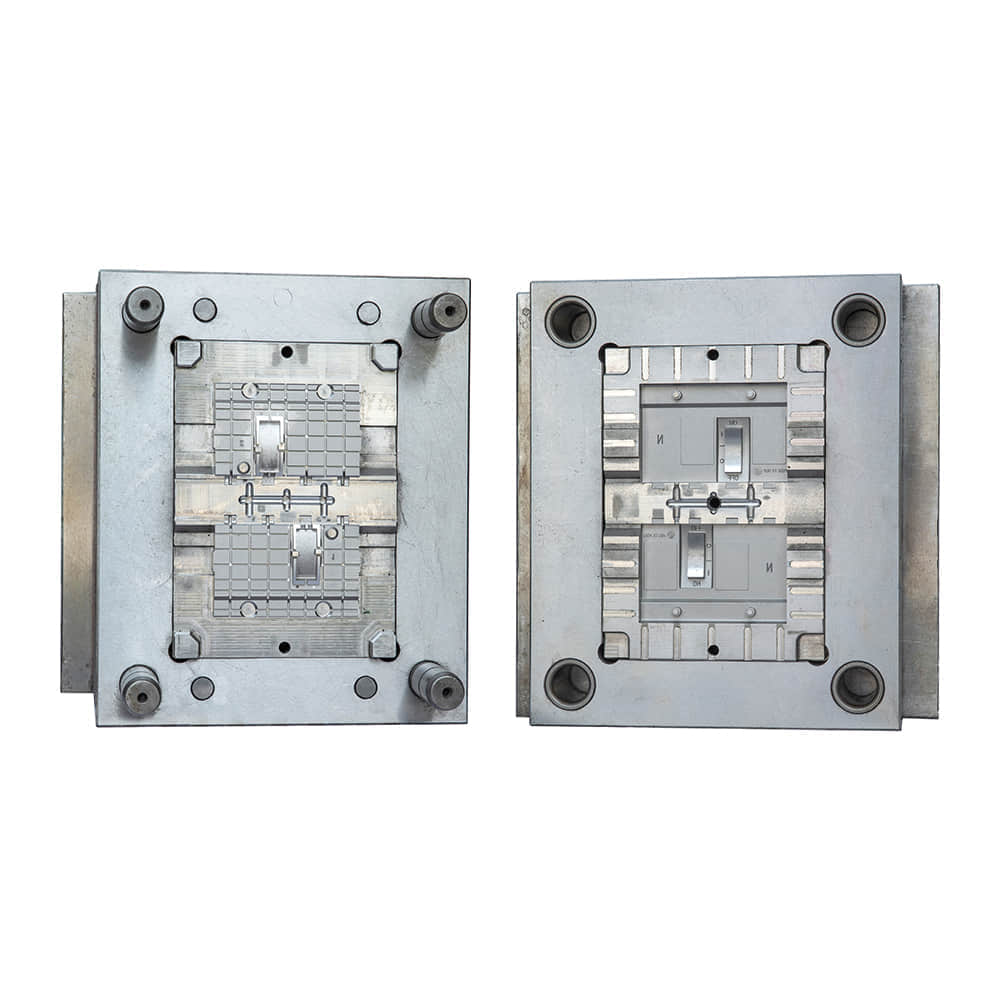

The Foundation of Precision Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity. Once cooled and solidified, the material takes the shape of the mold, resulting in a precise and consistent product. This process offers numerous advantages, including high production efficiency, intricate design possibilities, and reduced waste generation. Tailored Solutions for Diverse Industries The impact of injection molded parts manufacturers extends across a diverse range of industries. In the automotive sector, these parts are integral to creating lightweight, durable components that enhance vehicle performance and fuel efficiency. Medical equipment manufacturers rely on injection molding to produce sterile and reliable products, while the consumer electronics industry benefits from the ability to manufacture intricate casings and connectors. Whether it’s aerospace, packaging, or household appliances, injection molded parts have found their way into nearly every facet of modern living. Innovation Redefined In the world of injection molding, innovation is the driving force that propels the industry forward. Manufacturers are constantly pushing the boundaries of what’s possible, embracing new materials, technologies, and techniques. With the advent of advanced materials like bioplastics and composite polymers, injection molded parts are becoming more sustainable and environmentally friendly. Technological advancements are also reshaping the manufacturing process itself. Computer-aided design (CAD) software allows for the creation of intricate and complex molds with unmatched precision. Automation and robotics have streamlined production lines, reducing human error and enhancing efficiency. Additive manufacturing techniques, often known as 3D printing, are even being integrated with injection molding to create hybrid processes that offer the best of both worlds. Meeting Challenges Head-On While injection molding has revolutionized manufacturing, it’s not without its challenges. Manufacturers constantly grapple with balancing speed and cost-effectiveness with maintaining high quality standards. Ensuring consistent material properties, preventing defects, and reducing production waste require continuous refinement of processes and technologies. A Greener Future In response to growing environmental concerns, injection molded parts manufacturers are striving to create a more sustainable industry. By adopting biodegradable materials and optimizing production processes to minimize waste, they are contributing to a greener future. Recycling initiatives are also being explored, where used plastic components can be reprocessed to create new products, reducing the strain on raw materials. The Human Touch Behind every injection molded part lies the expertise of skilled engineers, designers, and technicians. Their ability to design intricate molds, troubleshoot production issues, and innovate new solutions remains crucial. The human element, combined with cutting-edge technology, is what sets apart exceptional manufacturers from the rest. Conclusion The world of injection molded parts manufacturing is a dynamic landscape where innovation and expertise converge. These manufacturers are the unsung heroes of modern life, enabling progress across industries and transforming the way we interact with products. As technology continues to advance and environmental awareness grows, the role of injection molded parts manufacturers in shaping a sustainable and innovative future is more important than ever before.