Metal Stamping Die Manufacturer: Precision, Innovation, and Excellence

In the world of manufacturing, precision and innovation are paramount. When it comes to metal stamping, the role of a Metal Stamping Die Manufacturer cannot be overstated. These unsung heroes of the manufacturing industry play a crucial role in creating the components that drive various sectors, from automotive to electronics. In this article, we will delve into the world of Metal Stamping Die Manufacturers, exploring their importance, innovative practices, and commitment to excellence.

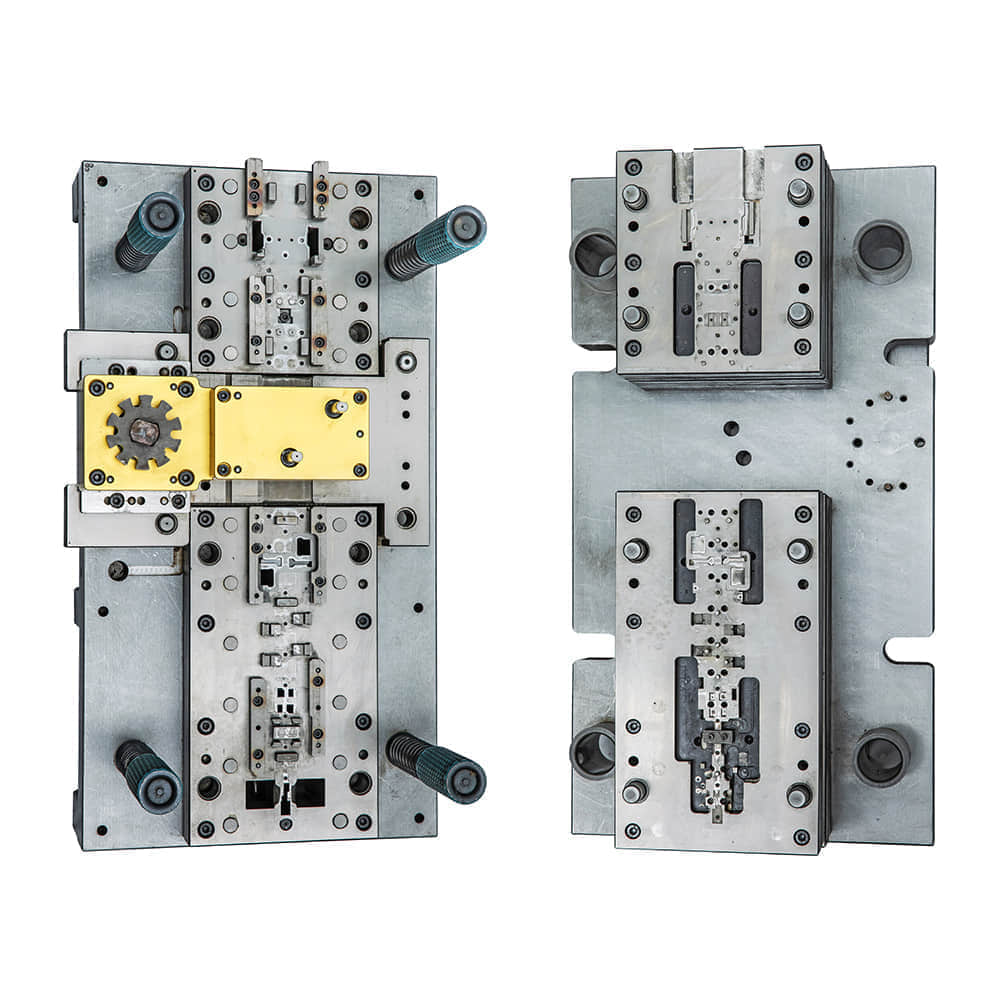

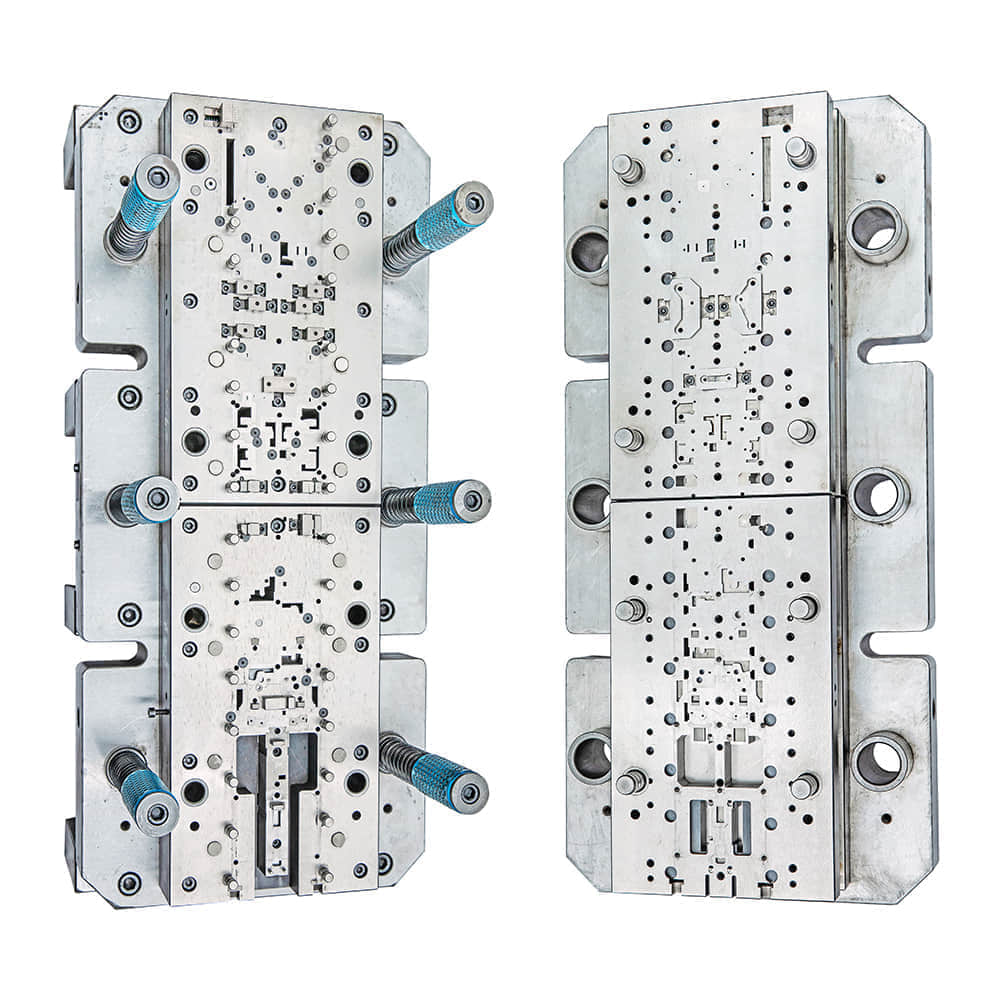

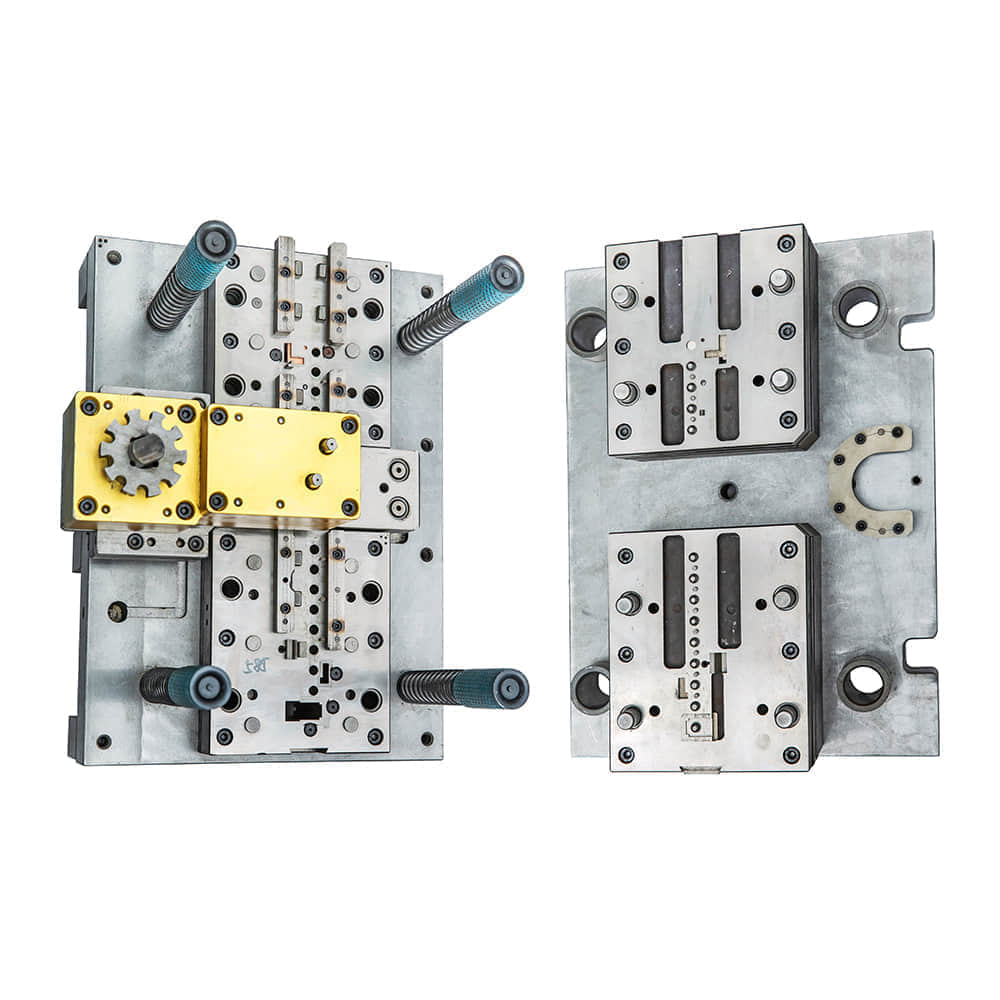

The Backbone of Manufacturing Metal stamping is a process used to create parts and components from sheet metal. It involves the use of specialized tools and dies to cut, shape, and transform metal sheets into precise, uniform parts. These parts can range from simple brackets to intricate automotive components. The accuracy and quality of these parts depend on the precision of the dies used in the stamping process. This is where Metal Stamping Die Manufacturers come into play. They are the architects behind the dies that enable mass production of high-quality metal components. Their expertise lies not only in creating dies but also in optimizing them for efficiency and longevity. Precision is the foundation of their craft, as even the slightest deviation can result in defective parts and production delays. Innovative Design and Technology Innovation is at the heart of the metal stamping industry. To meet the ever-evolving demands of various sectors, Metal Stamping Die Manufacturers must continuously innovate in their die design and manufacturing processes. Here are some key areas where innovation shines: Material Selection: Choosing the right material for stamping dies is crucial. Innovative manufacturers explore advanced materials and coatings that enhance die durability and reduce wear and tear, ultimately extending the lifespan of the dies. Computer-Aided Design (CAD): Modern Metal Stamping Die Manufacturers leverage CAD technology to design intricate and complex dies with unparalleled precision. CAD allows for rapid prototyping and fine-tuning of die designs, reducing lead times and costs. Simulation: Die manufacturers use simulation software to predict and optimize the stamping process. This enables them to identify potential issues, such as wrinkles or cracks in the metal, before actual production, saving both time and resources. Automation: Automation has revolutionized the metal stamping industry. Manufacturers are increasingly integrating robotics and artificial intelligence into their processes to improve efficiency, reduce errors, and enhance overall productivity. Commitment to Excellence Excellence is the ultimate goal for Metal Stamping Die Manufacturers. Achieving excellence requires a steadfast commitment to quality control and continuous improvement. Here’s how they maintain their dedication to excellence: Quality Control: Rigorous quality control measures are in place at every stage of die manufacturing. This includes thorough inspections, testing, and fine-tuning to ensure that each die meets the highest standards. Client Collaboration: Metal Stamping Die Manufacturers work closely with their clients to understand their specific needs and requirements. This collaboration fosters a culture of excellence and ensures that the final product aligns perfectly with the client’s vision. Training and Skill Development: Die manufacturers invest in the training and development of their workforce. Skilled craftsmen are essential for creating precision dies, and ongoing training keeps them at the forefront of the industry. Environmental Responsibility: Many die manufacturers are adopting eco-friendly practices, such as recycling materials and reducing energy consumption, to contribute positively to the environment while maintaining excellence in their products. Conclusion In the world of manufacturing, Metal Stamping Die Manufacturers are the unsung heroes who provide the foundation for precision and innovation. Their expertise, commitment to excellence, and innovative practices drive industries forward by delivering high-quality metal components that are integral to our daily lives. As technology continues to advance, we can expect Metal Stamping Die Manufacturers to lead the way, pushing the boundaries of what is possible in the world of metal stamping.