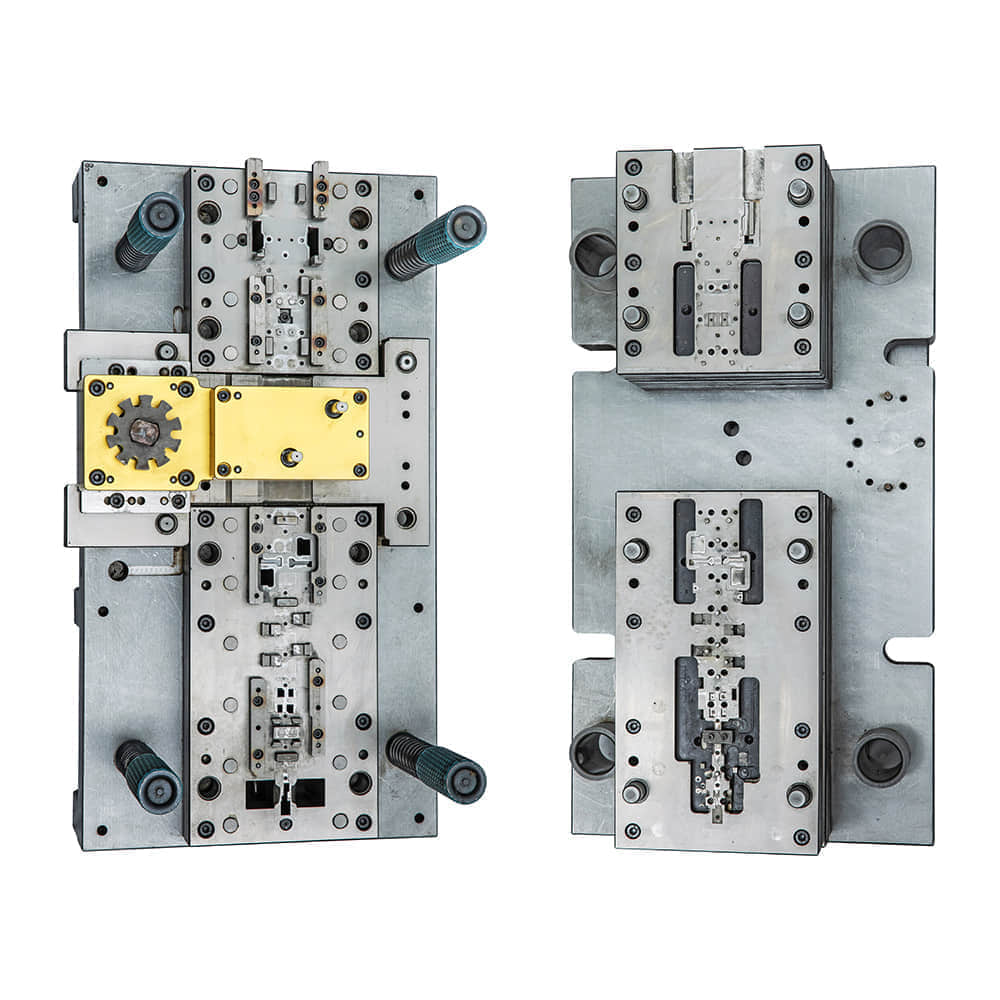

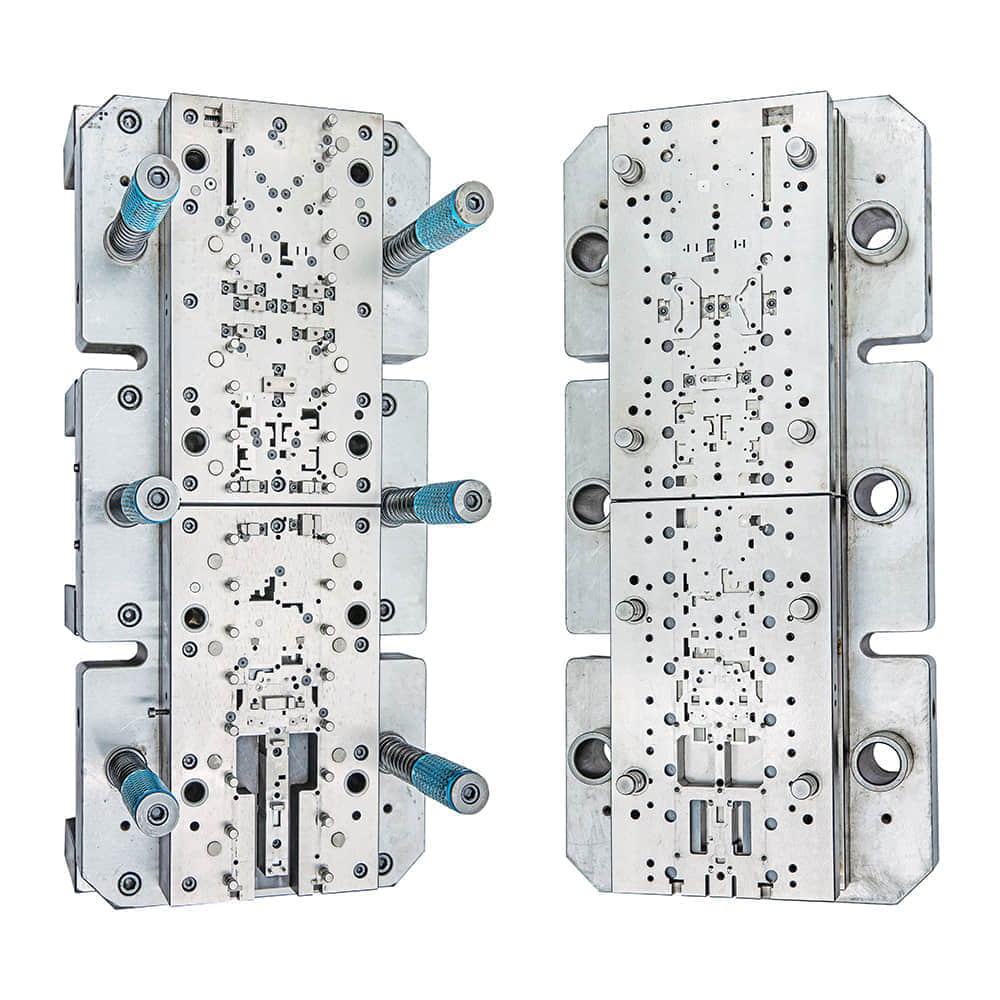

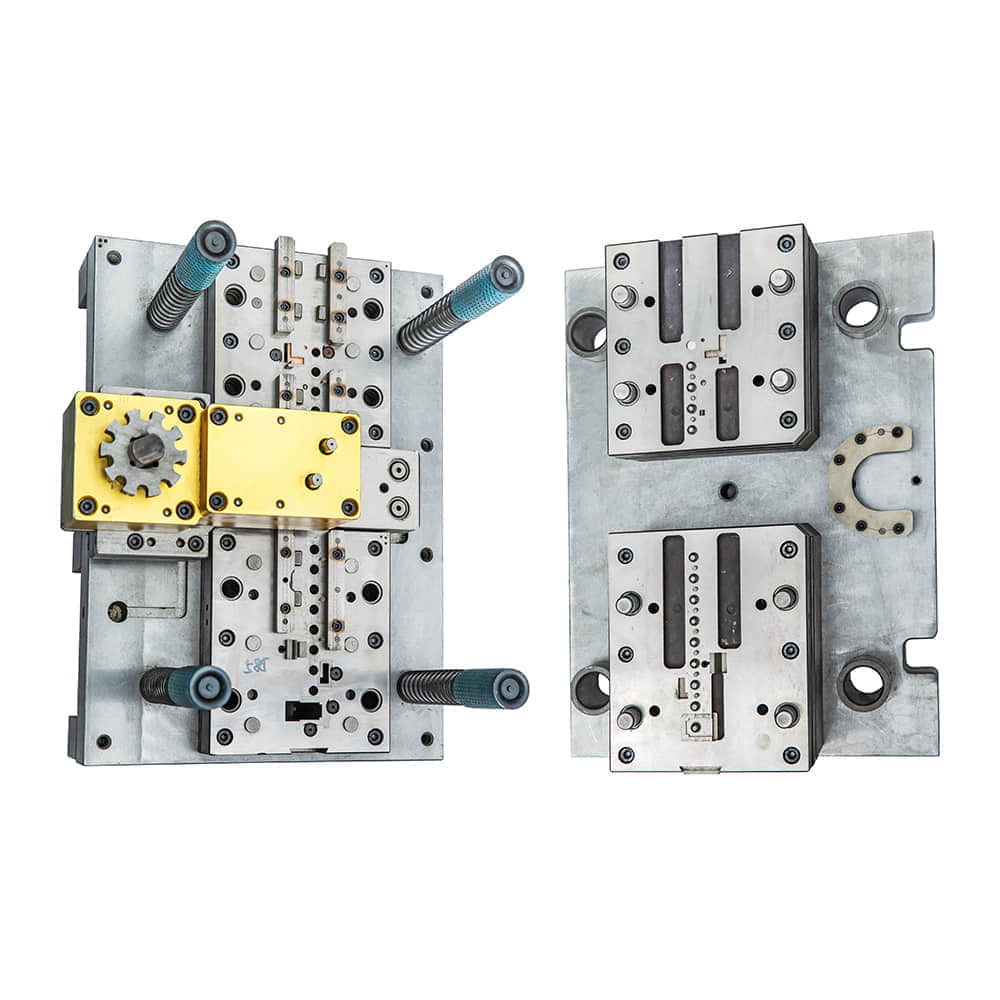

In the realm of modern manufacturing, precision and innovation are paramount. One industry that epitomizes these principles is metal stamping die manufacturing. These essential components play a crucial role in shaping various metal products that we use daily, from automotive parts to consumer electronics. Behind the scenes, Metal Stamping Die OEM Manufacturers are the unsung heroes driving this intricate process, seamlessly blending traditional craftsmanship with cutting-edge technology.

Metal stamping dies are specialized tools used to shape and cut metal sheets into specific forms with high accuracy and consistency. These dies are the backbone of industries requiring mass production of metal parts. To delve into the world of Metal Stamping Die OEM Manufacturers is to explore a landscape where skills meet innovation.

Craftsmanship: At the core of Metal Stamping Die OEM manufacturing is craftsmanship. Expert craftsmen with years of experience meticulously design and fabricate these dies. They have an intuitive understanding of metallurgy, mechanics, and engineering principles. Their hands-on approach, honed through years of practice, enables them to create dies that can withstand the forces involved in metal stamping while maintaining precision down to the micrometer level. It’s a fusion of art and engineering that results in tools capable of producing flawless metal components. Precision: The hallmark of a reliable Metal Stamping Die OEM Manufacturer is precision. Every millimeter counts in the manufacturing process. The slightest deviation can lead to defective parts or production line disruptions. These manufacturers utilize advanced software and CNC (Computer Numerical Control) machining to ensure the utmost precision in die creation. The seamless marriage of human expertise and technological advancements leads to dies that consistently produce accurate parts, contributing to the overall quality of the final products. Innovation: While tradition and craftsmanship form the foundation, Metal Stamping Die OEM Manufacturers are also trailblazers of innovation. They are quick to adopt the latest technologies to streamline and enhance their processes. Advanced simulations and modeling tools help them predict how different metals will behave under various conditions, enabling them to design dies that optimize material usage and minimize waste. Additionally, they explore novel materials and coatings that extend the lifespan of dies, improving cost-efficiency and sustainability. Customization: Each industry and product comes with unique requirements. Metal Stamping Die OEM Manufacturers excel in customization. They collaborate closely with clients to understand their needs and tailor the die designs accordingly. This flexibility ensures that the manufactured parts meet specific quality, size, and shape criteria. Whether it’s a complex automotive component or a delicate electronic part, these manufacturers adapt their expertise to create dies that yield perfect results. Global Impact: The influence of Metal Stamping Die OEM Manufacturers reverberates globally. As industries evolve, the demand for precision metal parts grows, underscoring the critical role these manufacturers play. Their ability to produce high-quality dies efficiently contributes to the smooth functioning of various supply chains. From aerospace to medical equipment, their impact is felt across a spectrum of sectors that rely on accurate and reliable metal components. In conclusion, Metal Stamping Die OEM Manufacturers represent the synergy of traditional craftsmanship and modern innovation. Their commitment to precision, customization, and staying at the forefront of technology ensures that the products we use daily are of the highest quality. As we marvel at the sleek automobiles, robust appliances, and intricate electronics that enrich our lives, let us not forget the unsung heroes behind the scenes – the Metal Stamping Die OEM Manufacturers who shape the metals that shape our world.