Metal stamping is a crucial process in the world of manufacturing, playing a pivotal role in the creation of various products we use in our daily lives. Whether it’s the components in your car, the appliances in your home, or even the gadgets you rely on, metal stamping parts are behind the scenes, ensuring precision, durability, and reliability.

The Basics of Metal Stamping Parts

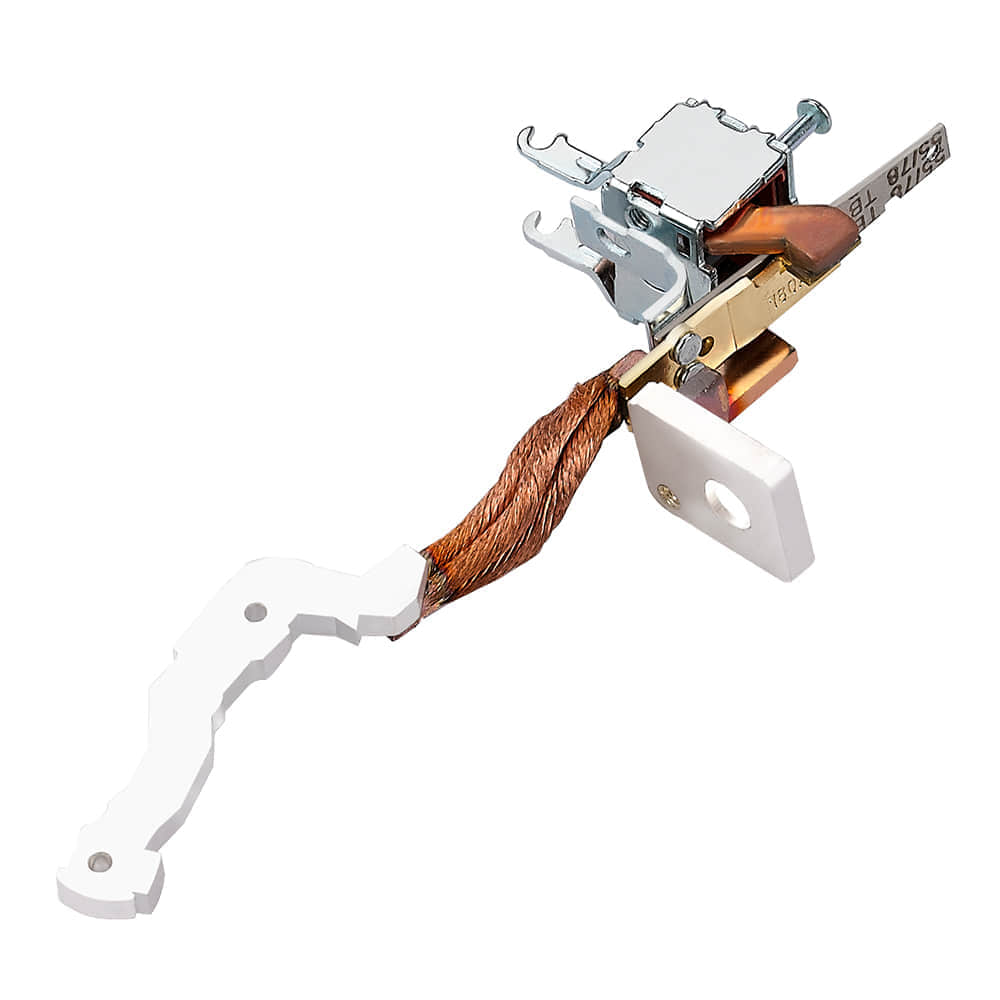

Metal stamping is a manufacturing process where flat sheet metal is shaped into a desired form using a press and a die. This process involves various techniques such as blanking, bending, punching, and coining to transform raw metal sheets into intricate parts and components. Manufacturers use a wide range of metals, including steel, aluminum, copper, and more, depending on the specific requirements of the product. Precision and Consistency One of the primary reasons for the popularity of metal stamping is its ability to deliver precise and consistent results. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software has revolutionized this industry, allowing engineers to create intricate designs with micron-level accuracy. This precision is vital in industries such as aerospace and electronics, where even the slightest deviation can lead to catastrophic consequences. Cost-Effective Production Metal stamping is also known for its cost-effectiveness. The high-speed production capabilities of stamping machines, coupled with minimal material wastage, make it an efficient method for mass production. Moreover, the durability and longevity of stamped parts contribute to reduced maintenance and replacement costs, making it an attractive option for manufacturers looking to optimize their production processes. Versatility in Design Metal stamping offers a high degree of versatility in design. Engineers can create a wide range of shapes and sizes, from simple brackets to complex gears and connectors. The ability to produce intricate parts with tight tolerances makes it a preferred choice in industries where custom solutions are essential. Furthermore, the versatility extends to the choice of materials, enabling manufacturers to select the most suitable metal for a specific application. Environmental Sustainability In an era where environmental concerns are paramount, metal stamping has also shown its commitment to sustainability. Many manufacturers now use recycled materials, and the efficient production process minimizes waste generation. Additionally, the durability and longevity of stamped parts reduce the need for frequent replacements, further lowering the environmental impact. Applications in Various Industries Metal stamping parts find applications in a multitude of industries, showcasing their adaptability and importance. In the automotive sector, they are used to create components like engine brackets, chassis parts, and suspension components. In the electronics industry, metal stamping is vital for producing connectors, terminals, and enclosures. The aerospace sector relies on stamped parts for aircraft components, ensuring safety and reliability. Challenges and Innovations While metal stamping has come a long way, it still faces challenges. High initial tooling costs can be a barrier for small-scale manufacturers, and the complexity of some designs may require extensive testing and adjustments. However, ongoing innovations in materials, die technologies, and automation are addressing these challenges, making metal stamping even more accessible and efficient. Conclusion Metal stamping parts are the unsung heroes of modern manufacturing, driving precision, consistency, and cost-effectiveness across various industries. Their adaptability, sustainability, and ability to meet exacting standards make them an indispensable part of our everyday lives. As technology continues to advance, we can expect even more remarkable developments in the world of metal stamping, further enhancing its role in shaping the products of the future.