Metal stamping is a manufacturing process that plays a pivotal role in various industries, offering precision, versatility, and industrial excellence. In this article, we will explore the world of metal stamping parts, delving into their significance, applications, and the key factors that make them indispensable in modern manufacturing.

The Significance of Metal Stamping Parts

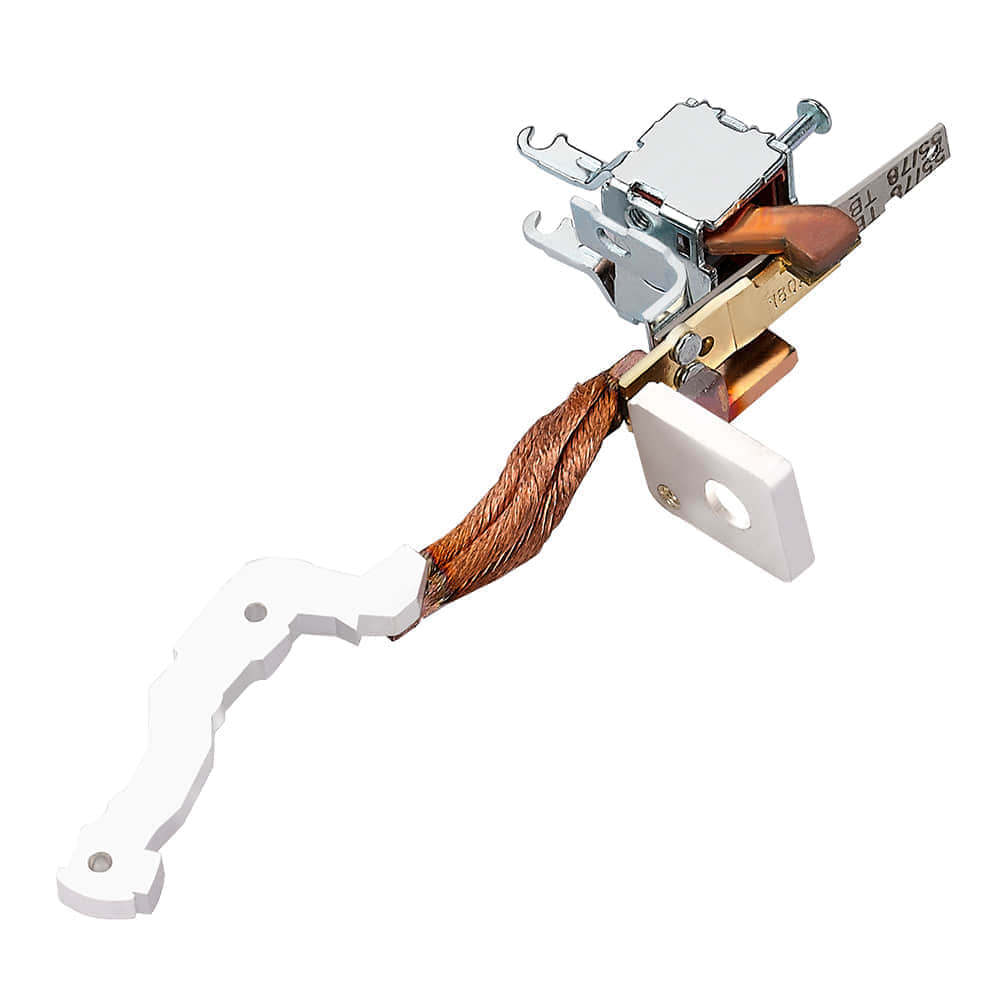

Metal stamping parts are the backbone of many manufacturing industries, owing to their exceptional precision and cost-effectiveness. This manufacturing process involves forming, cutting, and shaping metal sheets into various designs and configurations. It offers numerous advantages, making it an essential component of various sectors, including automotive, aerospace, electronics, and more. Versatility in Design and Functionality One of the primary advantages of metal stamping parts is their versatility. Manufacturers can create intricate and complex designs with ease, thanks to advanced stamping technologies. Whether it’s producing small, intricate components or large, structural parts, metal stamping can accommodate a wide range of requirements. This adaptability extends to the choice of materials, allowing for the creation of parts from various metals, including steel, aluminum, brass, and copper. Applications Across Industries The automotive industry heavily relies on metal stamping parts. From chassis components to engine parts and interior fittings, metal stamping ensures that vehicles are not only durable but also efficient. The precision of metal stamping plays a crucial role in enhancing vehicle safety and performance. In the aerospace sector, the demand for lightweight yet robust components is ever-growing. Metal stamping answers this need by producing intricate parts like brackets, connectors, and panels with high strength-to-weight ratios. These parts are essential for ensuring aircraft safety and fuel efficiency. Electronics, too, benefit significantly from metal stamping. The process is used to create connectors, shielding, and various components that are crucial for the functionality and reliability of electronic devices. The precision and consistency of metal stamping parts are instrumental in maintaining the quality of these products. The Role of Technology Advancements in technology have revolutionized the field of metal stamping. Computer Numerical Control (CNC) machines, for instance, enable precise control over the stamping process. This not only enhances the quality of the parts but also reduces waste and production time. Additionally, 3D modeling and simulation software allow manufacturers to optimize designs and identify potential issues before production begins. Quality Assurance and Consistency Quality control is paramount in metal stamping. Manufacturers employ rigorous inspection processes to ensure that each stamped part meets the required specifications. This commitment to quality extends beyond individual parts to the overall production process. Quality assurance measures such as statistical process control (SPC) and Six Sigma methodologies help maintain consistency and minimize defects. Environmental Sustainability Metal stamping is also aligning with the growing emphasis on environmental sustainability. By reducing material waste and energy consumption, metal stamping contributes to more eco-friendly manufacturing practices. The recyclability of metal further underscores its environmental benefits. Conclusion Metal stamping parts are a linchpin of modern manufacturing, underpinning the success of numerous industries. Their precision, versatility, and adaptability are indispensable, enabling the creation of high-quality, cost-effective components. As technology continues to advance, metal stamping will play an even more vital role in shaping the future of manufacturing, promoting innovation, and supporting sustainable practices. With these attributes, metal stamping parts will remain a cornerstone of industrial excellence for years to come.