When it comes to designing electrical systems and automation solutions, the selection of appropriate relays plays a pivotal role in ensuring reliability, efficiency, and safety. Relay type selection involves a multifaceted approach that takes into account various technical specifications, application requirements, and environmental conditions. This article aims to provide a comprehensive guide on the factors to consider when selecting relay types, ensuring that engineers can make informed decisions in their projects.

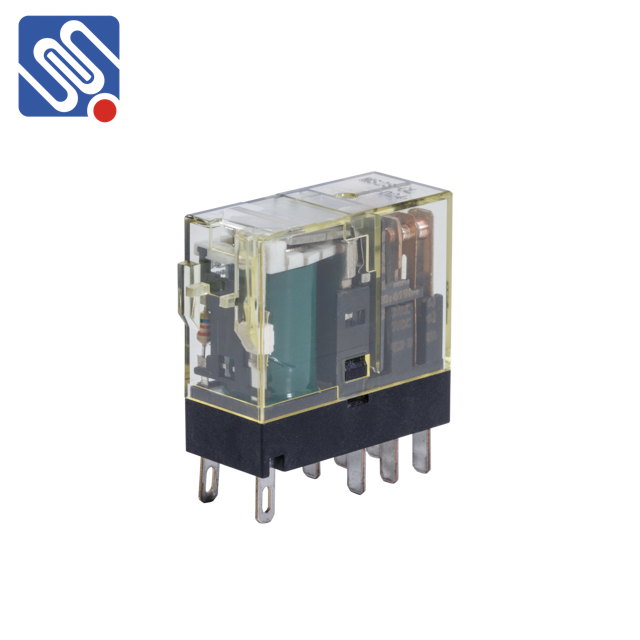

Understanding Relay Types Relays can be broadly classified into two main categories: electromagnetic relays and solid-state relays (SSRs). Electromagnetic Relays function by using an electromagnetic coil to mechanically operate a switch. They are widely used due to their simplicity and cost-effectiveness. However, they have some limitations, such as slower response times and limited life cycles due to mechanical wear. On the other hand, Solid-State Relays utilize semiconductor technology to switch loads without any moving parts. This absence of mechanical components allows SSRs to achieve faster switching times and significantly longer operational lifespans. These characteristics make them particularly suitable for high-frequency and high-reliability applications.