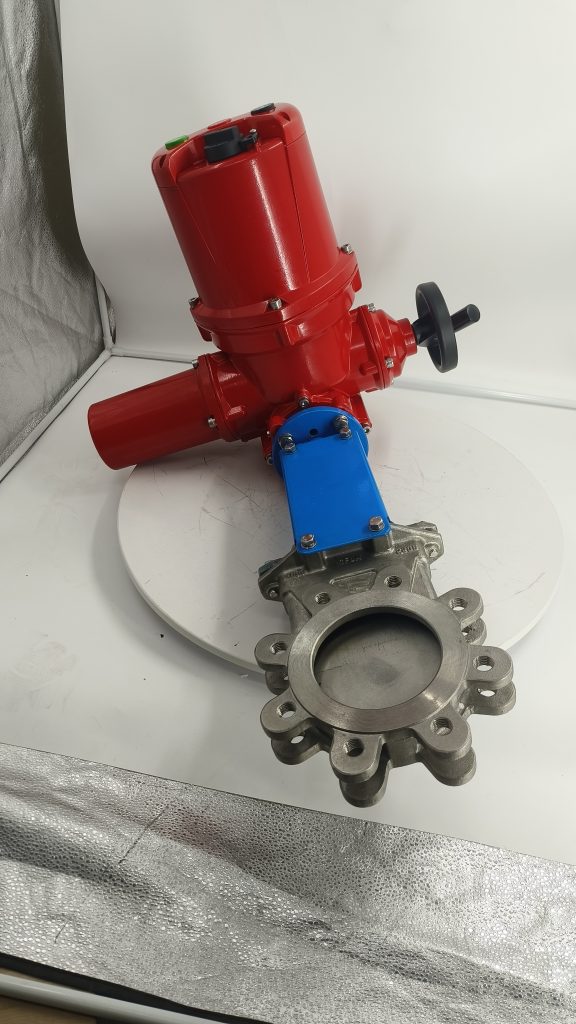

首先,由于氢气具有易燃易爆的特性,因此在设计氢能源电动切断阀时,会特别注重其安全性和可靠性。阀门材料通常会选择能够耐受氢气环境、耐腐蚀且强度高的材料,以确保阀门在长期使用中能够保持稳定的性能。

其次,氢能源电动切断阀通常会配备先进的控制系统和传感器,用于实时监测氢气流量、压力、温度等关键参数。当这些参数超出安全范围时,控制系统会迅速响应,驱动切断阀关闭,防止氢气泄漏或其他安全事故的发生。

此外,随着氢能源技术的不断发展,氢能源电动切断阀也在不断进行技术创新和优化。例如,一些先进的切断阀可能采用智能控制算法,根据系统的实时状态和需求进行自适应调整,以实现更高效、更安全的运行。 总的来说,氢能源电动切断阀作为氢能源系统中的重要安全装置,其设计、制造和应用都需要严格遵守相关标准和规范,以确保其在实际使用中的可靠性和有效性。同时,随着技术的不断进步和应用领域的不断拓展,氢能源电动切断阀的性能和功能也将不断提升和完善。 关于氢能源电动切断阀(Hydrogen energy electric shut-off valve),其设计和应用还涉及到多个层面的考虑。 首先,在环保和节能方面,氢能源电动切断阀作为氢能源系统的一部分,其设计也会考虑到节能减排的需求。电动切断阀通常采用电力驱动,相较于传统的气动或液压驱动方式,电力驱动具有更高的能效和更低的排放。此外,随着可再生能源技术的不断发展,电动切断阀也可以与太阳能、风能等可再生能源发电系统相结合,进一步降低能源消耗和环境污染。 其次,在智能化和网络化方面,氢能源电动切断阀正逐渐融入工业自动化和物联网技术。通过集成传感器、通信模块和智能控制算法,电动切断阀可以实现远程监控、故障诊断和自动控制等功能。这不仅可以提高系统的运行效率和安全性,还可以降低维护成本和人力成本。 此外,氢能源电动切断阀的应用范围也在不断拓展。除了传统的氢气储存和输送系统,它还可以应用于氢燃料电池汽车、氢能发电站等新兴领域。随着氢能源技术的不断推广和应用,氢能源电动切断阀的市场需求也将不断增长。