The Marine Electric Butterfly Valve stands as a pivotal component in the intricate network of shipboard fluid control systems. Its unique design and functionality make it a vital tool for efficient and safe marine operations. This article delves into the intricacies of this valve, highlighting its importance and the various factors that contribute to its effectiveness.

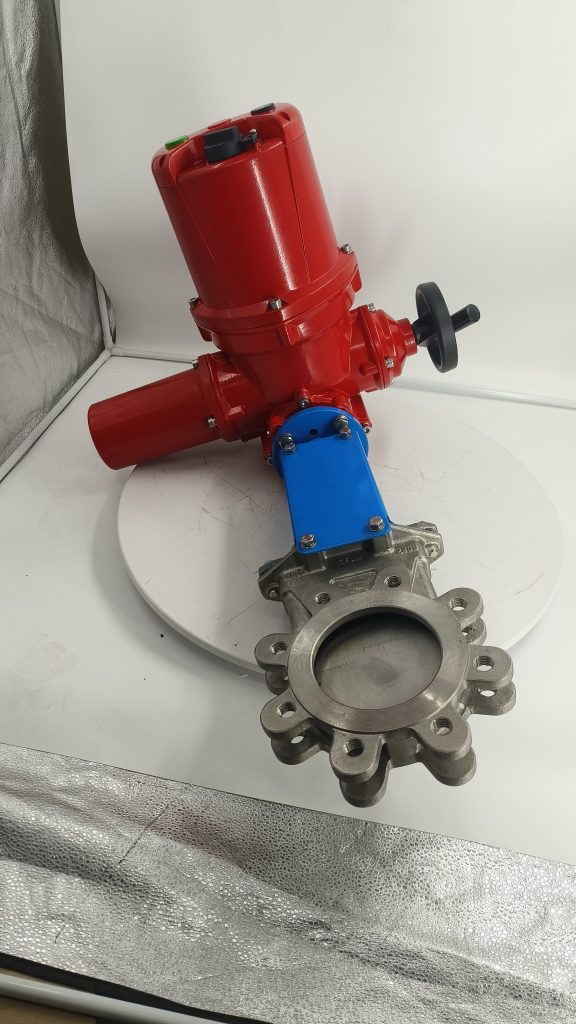

The Marine Electric Butterfly Valve combines the precision of an electric actuator with the versatility of a butterfly valve, creating a powerful tool for managing fluid flow in ships. Its electric actuator allows for remote control and automation, ensuring seamless integration into modern shipboard systems. Meanwhile, the butterfly valve’s disc-like design allows for quick and efficient opening and closing, minimizing fluid loss and maximizing operational efficiency.

The valve’s compact size and lightweight construction make it an ideal choice for ships, where space is often limited. Its ability to handle a wide range of fluids, including both liquids and gases, further enhances its versatility. Whether it’s controlling the flow of seawater for cooling systems or regulating the supply of fuel to engines, the Marine Electric Butterfly Valve is a reliable and efficient solution. However, the effectiveness of the Marine Electric Butterfly Valve is not solely dependent on its design. Proper installation and maintenance are crucial for ensuring optimal performance. The valve must be carefully aligned with the pipeline to prevent leaks and ensure smooth operation. Regular inspections and maintenance are also necessary to identify and address any potential issues before they become larger problems.