In today’s fast-paced manufacturing landscape, injection molded parts play a pivotal role in numerous industries, from automotive to consumer electronics, medical devices to aerospace. These parts serve as the building blocks for a wide range of products, offering durability, precision, and cost-effectiveness. In this article, we will delve into the fascinating world of injection molded parts manufacturing, exploring its processes, innovations, and the key players in the industry.

The Art and Science of Injection Molded Parts Manufacturing

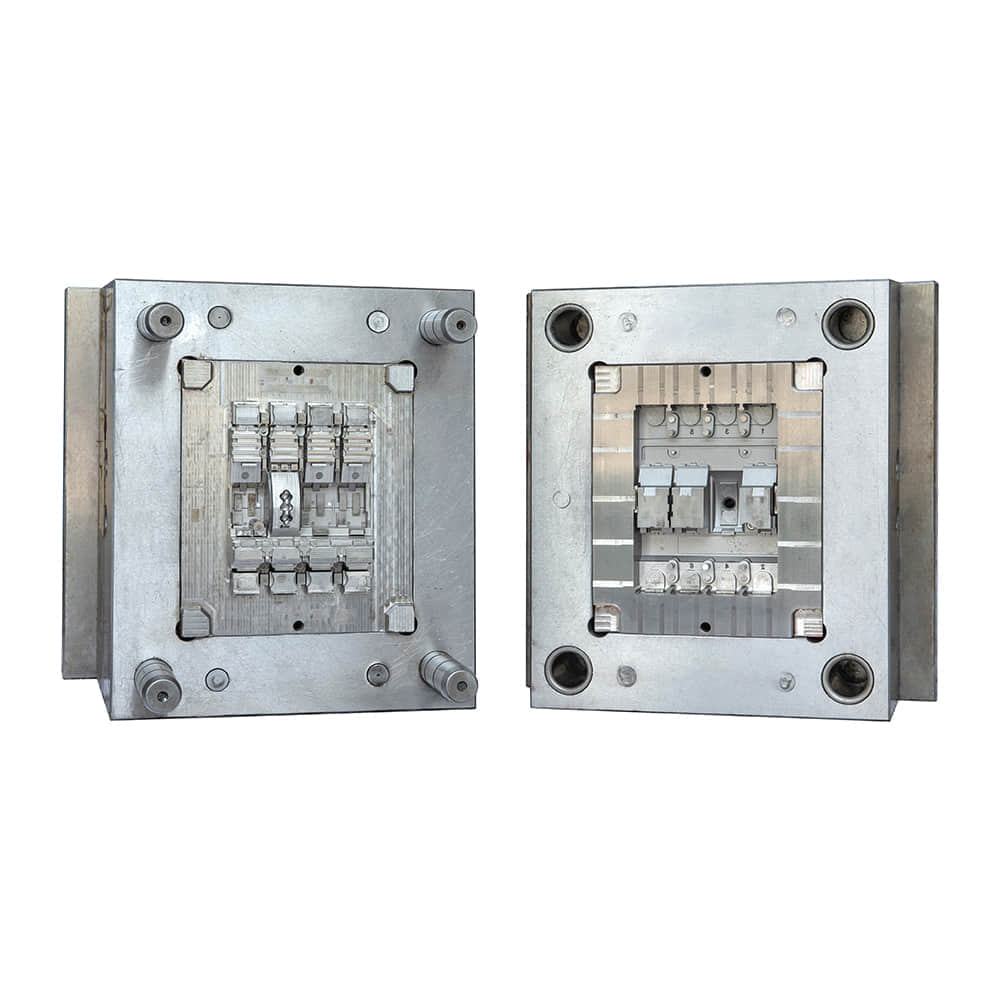

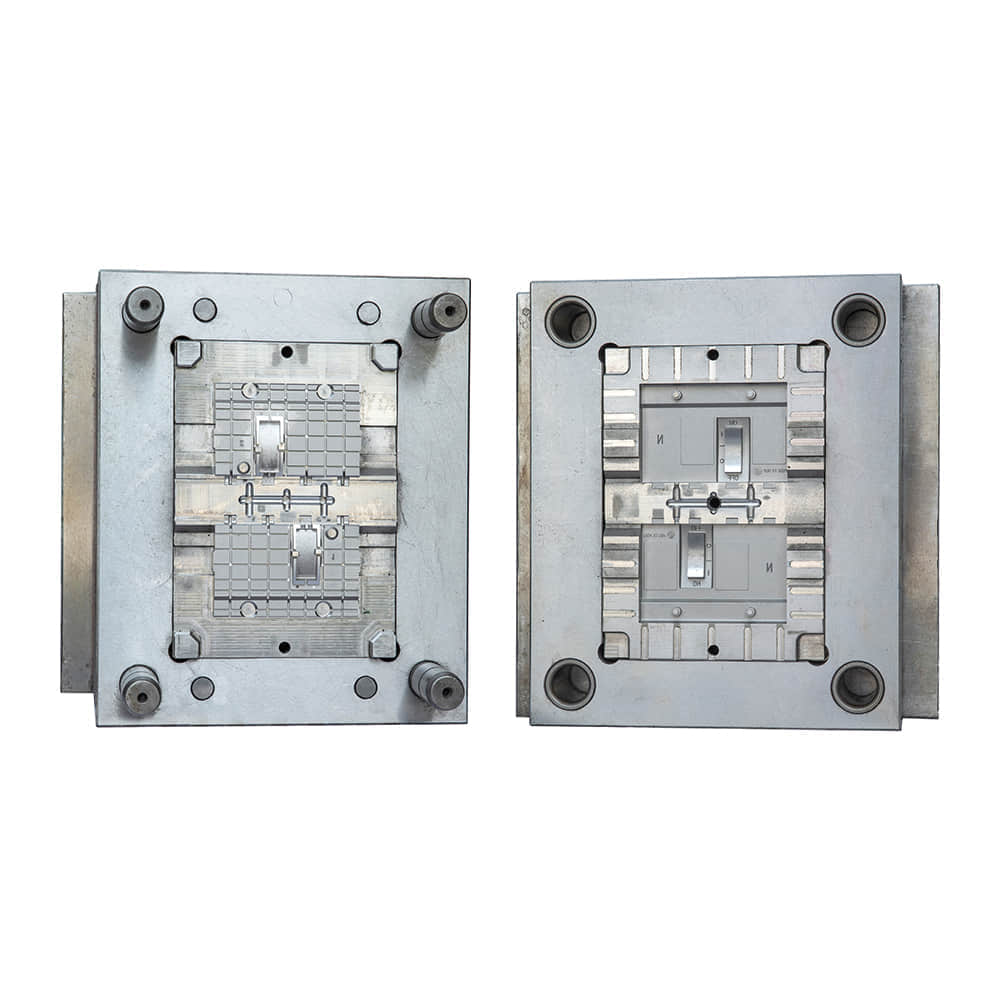

Injection molding is a manufacturing process that involves the creation of three-dimensional objects by injecting molten material into a mold. This technique allows for the mass production of intricate and precise parts, making it a cornerstone of modern manufacturing. The process begins with the design of a mold, often made of steel or aluminum, which serves as a negative of the desired part. The chosen material, typically a thermoplastic or thermosetting plastic, is then heated until it reaches a liquid state. It is injected under high pressure into the mold cavity and left to cool and solidify. Once the part is solid, the mold opens, and the finished product is ejected. Meeting Industry Demands Injection molded parts manufacturers are constantly adapting to meet the evolving demands of various industries. Automotive manufacturers, for instance, rely on injection molding for components like bumpers, dashboards, and interior trims. The medical industry demands precision and biocompatibility for devices such as syringes and implantable components. Consumer electronics require intricate, lightweight, and durable parts for devices like smartphones and laptops. To satisfy these diverse requirements, manufacturers invest heavily in research and development. They work on improving materials, enhancing mold designs, and refining manufacturing processes. Innovations in materials have led to the development of biodegradable plastics and materials that can withstand extreme temperatures and corrosive environments. Precision and Quality Control One of the key strengths of injection molding is its ability to produce parts with exceptional precision and consistency. Modern injection molding machines are equipped with advanced technology that allows for tight control over various parameters, including temperature, pressure, and cooling rates. This level of control ensures that each part meets exacting standards. Quality control is a top priority for injection molded parts manufacturers. Advanced inspection and testing methods are employed to detect any defects or inconsistencies in the final products. This meticulous attention to detail ensures that parts meet or exceed industry standards and customer expectations. Sustainability in Injection Molding With the growing emphasis on environmental responsibility, injection molded parts manufacturers are increasingly focusing on sustainability. Many are adopting eco-friendly materials, recycling practices, and energy-efficient manufacturing processes. The development of biodegradable plastics and recycling programs for post-consumer waste is a significant step towards reducing the environmental impact of injection molding. Leading Injection Molded Parts Manufacturers Several companies have risen to prominence as leaders in the injection molding industry. Names like Becton Dickinson, Flex Ltd., and Proto Labs are renowned for their expertise in producing high-quality, precision parts for a wide range of applications. These companies have invested heavily in research and development, automation, and sustainability initiatives to stay at the forefront of the industry. Conclusion Injection molded parts manufacturing is a dynamic and vital sector of the modern industrial landscape. It provides the foundation for countless products that enhance our daily lives and drive innovation across various industries. With a commitment to precision, innovation, and sustainability, injection molded parts manufacturers continue to play a crucial role in shaping the future of manufacturing. As technology advances and environmental concerns grow, we can expect this industry to evolve further, pushing the boundaries of what is possible in the world of precision manufacturing.