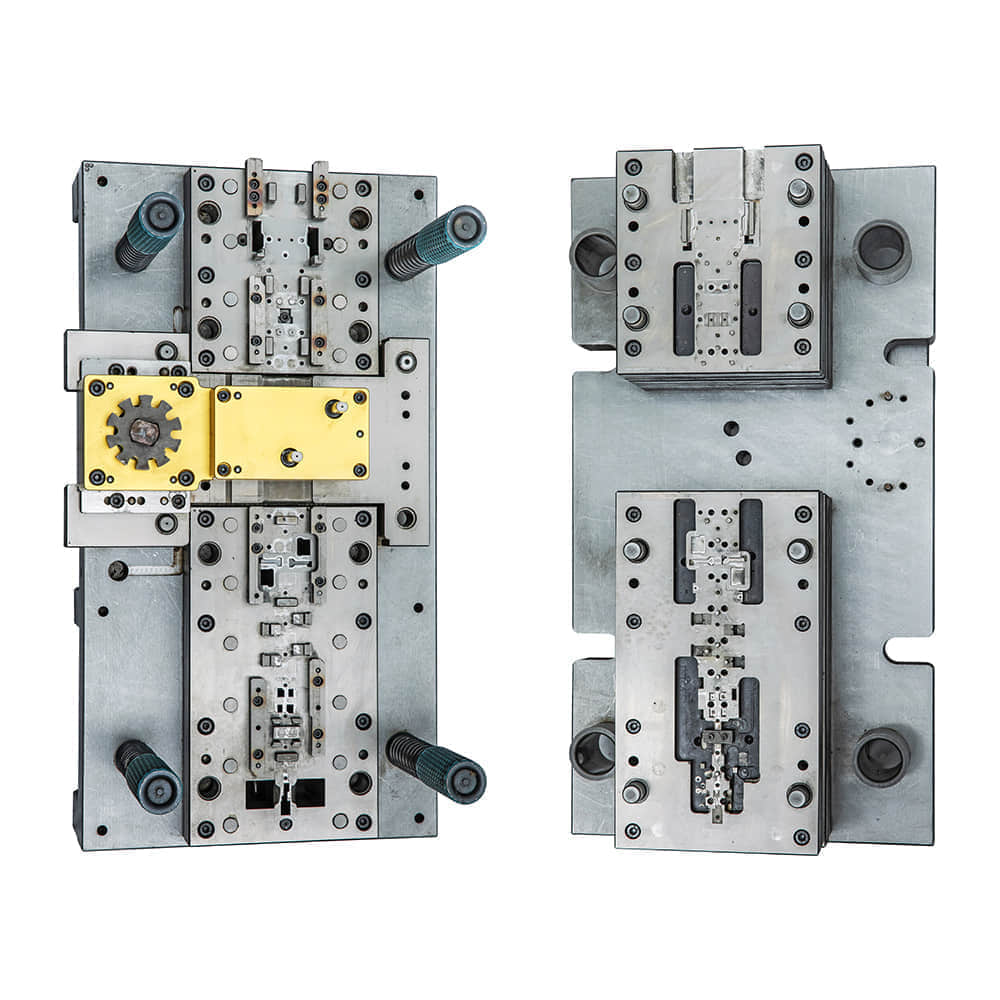

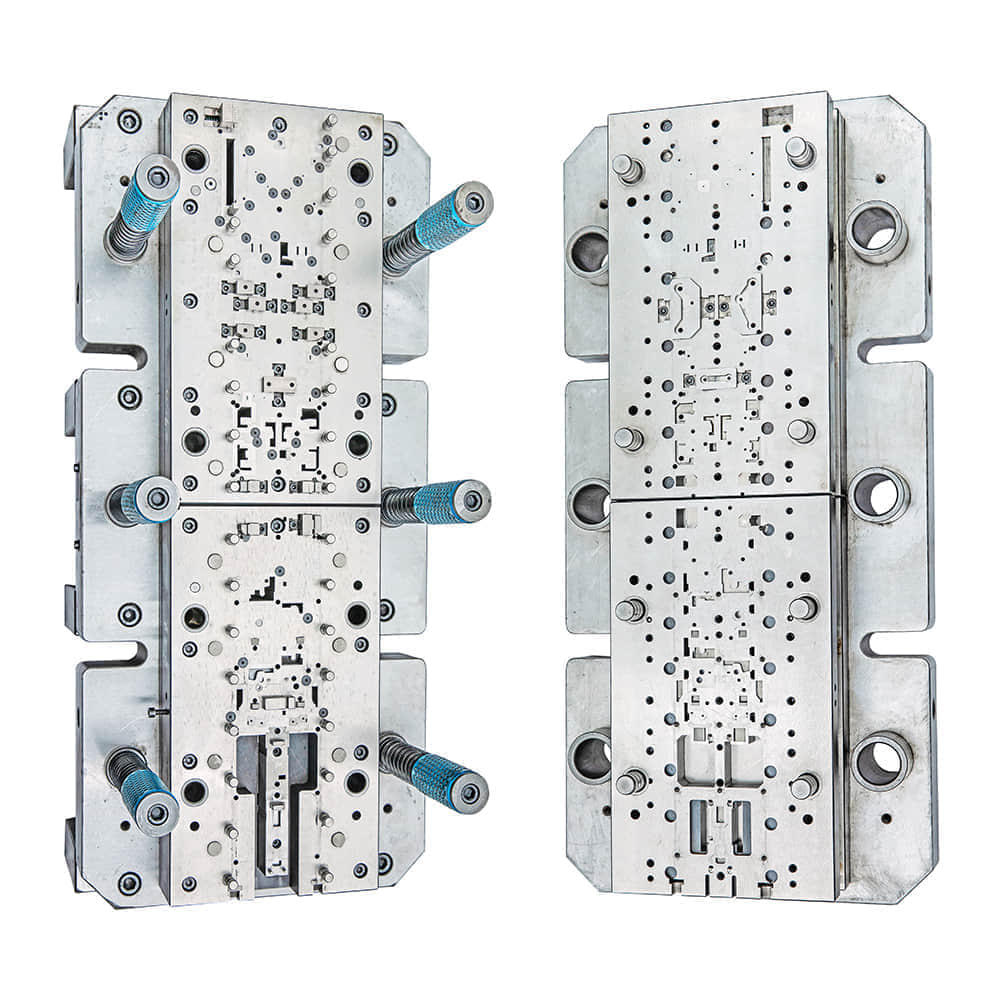

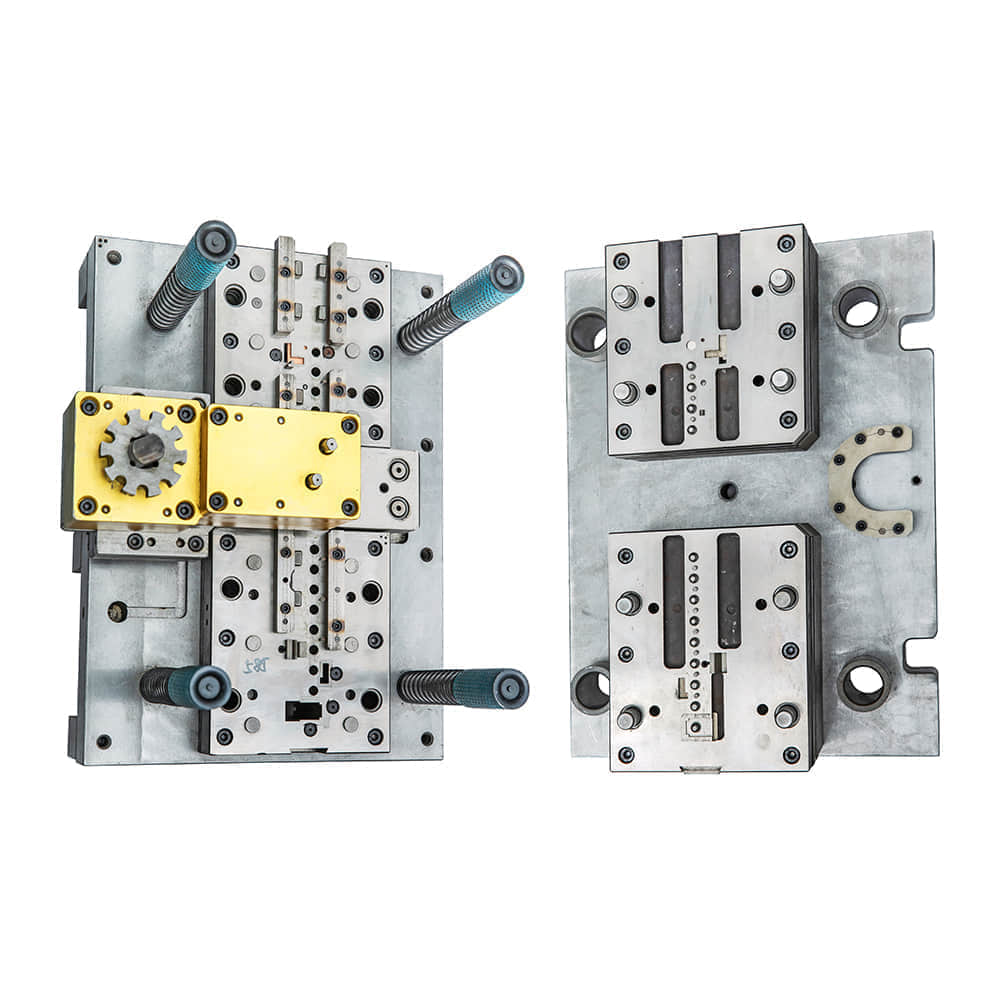

Metal stamping is a vital process in the world of manufacturing, and at its core lies a critical component – the metal stamping die. These meticulously crafted tools are the unsung heroes behind the mass production of countless products we use in our daily lives, from automobile parts to consumer electronics. In this article, we will delve into the fascinating world of metal stamping die manufacturing and explore the key aspects that make it an indispensable part of modern industry.

The Essence of Metal Stamping Die

At its essence, metal stamping die manufacturing is the art of creating customized tools used to shape and form metal sheets into desired shapes and patterns. These dies are typically made from high-quality tool steel or carbide and are engineered with precision to withstand immense pressure and repetitive use. The process involves a series of intricate steps, each of which contributes to the die’s functionality and longevity. Design Expertise The journey begins with design. Experienced engineers and designers meticulously plan the die’s shape and dimensions based on the specific requirements of the stamped part. This involves precise measurements, material selection, and complex calculations to ensure that the die can withstand the forces it will encounter during the stamping process. Advanced CAD (Computer-Aided Design) software aids in creating digital blueprints, which serve as the foundation for the physical die. Materials Matter Once the design is finalized, the choice of material becomes paramount. Tool steel and carbide are the go-to materials for their exceptional durability and resistance to wear and tear. Selecting the right material is crucial, as it directly influences the die’s lifespan and performance. Heat treatments and surface coatings are often applied to further enhance the die’s resilience. Precision Machining The heart of metal stamping die manufacturing lies in precision machining. Skilled machinists use state-of-the-art CNC (Computer Numerical Control) machines to transform raw materials into finely detailed dies. These machines operate with micron-level accuracy, ensuring that every cut and contour aligns perfectly with the design specifications. The result is a die that can replicate intricate shapes with remarkable consistency. Quality Assurance Quality control is an integral part of the process. Each die undergoes rigorous testing to ensure it meets the highest standards. This includes dimensional checks, hardness testing, and inspections for any imperfections. Only dies that pass these stringent tests move on to the next stage. The Art of Hand Finishing Despite the high level of automation, there is an art to hand finishing. Skilled craftsmen meticulously inspect and refine the die’s surfaces, removing any imperfections and ensuring that it meets the exacting requirements of the stamping process. This human touch is essential for achieving the finest results. The Stamping Process Once completed, metal stamping dies are ready to perform their magic. They are installed in stamping presses, where they exert immense force on metal sheets, transforming them into precise shapes. The speed, force, and precision of this process are truly remarkable, allowing for the high-speed production of complex parts. Endless Applications The reach of metal stamping die manufacturing is extensive, spanning industries as diverse as automotive, aerospace, electronics, and more. Whether it’s creating intricate components for cutting-edge technology or producing essential parts for everyday appliances, metal stamping dies play a pivotal role in driving industrial progress. Innovation Never Ends The world of metal stamping die manufacturing is far from stagnant. Continuous innovation in materials, machining techniques, and automation technologies ensures that these critical tools evolve alongside industry needs. This constant quest for improvement makes metal stamping die manufacturing an exciting field to watch. Conclusion In the realm of manufacturing, the craft of metal stamping die manufacturing often goes unnoticed, but its impact is profound. These precision-crafted tools are the backbone of mass production, enabling the creation of countless products that shape our modern world. From the careful design and material selection to the precision machining and hand finishing, every step in the process reflects the dedication and expertise of those who craft these essential components. As industries continue to advance, so too will the art of metal stamping die manufacturing, ensuring a bright future for this indispensable field.