In the vast world of manufacturing, metal stamping is a vital and intricate process that plays a significant role in creating countless products we use daily. From the smallest electronic components to large automotive parts, metal stamping manufacturers are at the forefront of precision engineering. In this article, we will delve into the fascinating world of metal stamping parts manufacturers and explore their crucial role in modern industry.

Metal Stamping: An Art of Precision

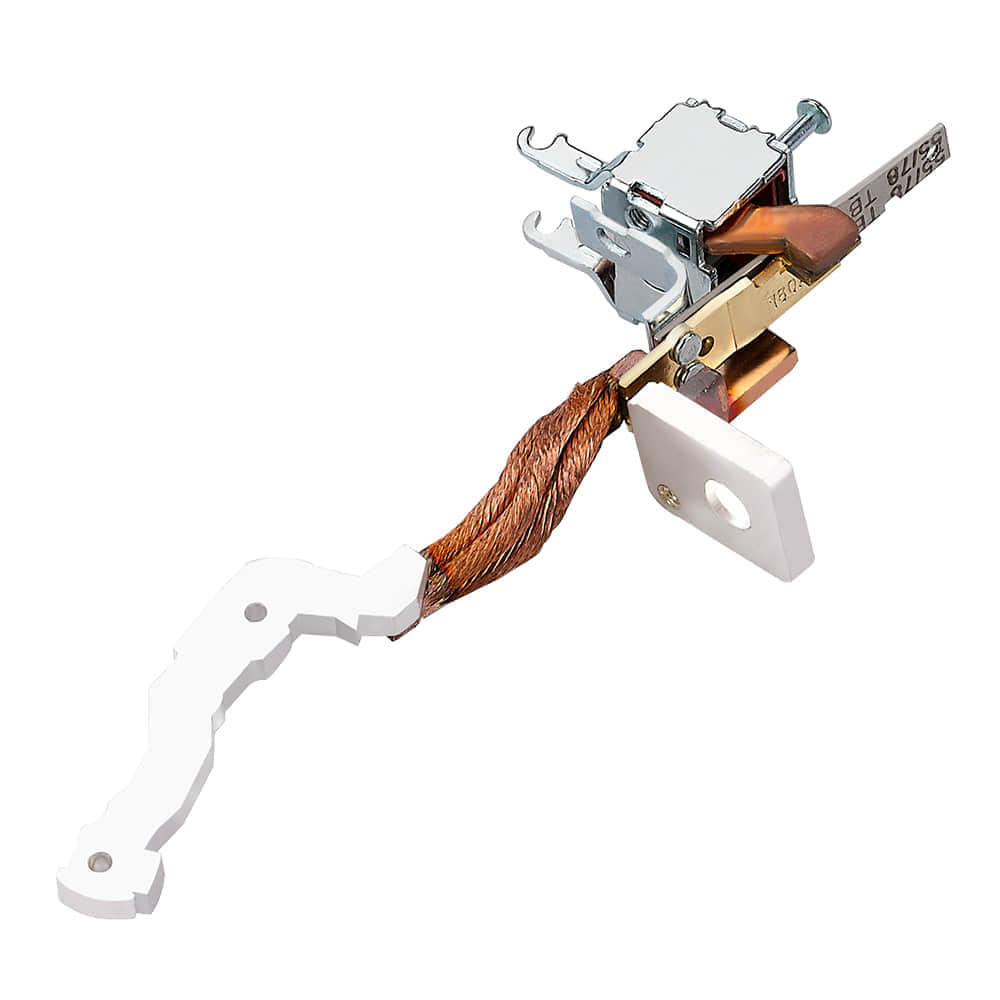

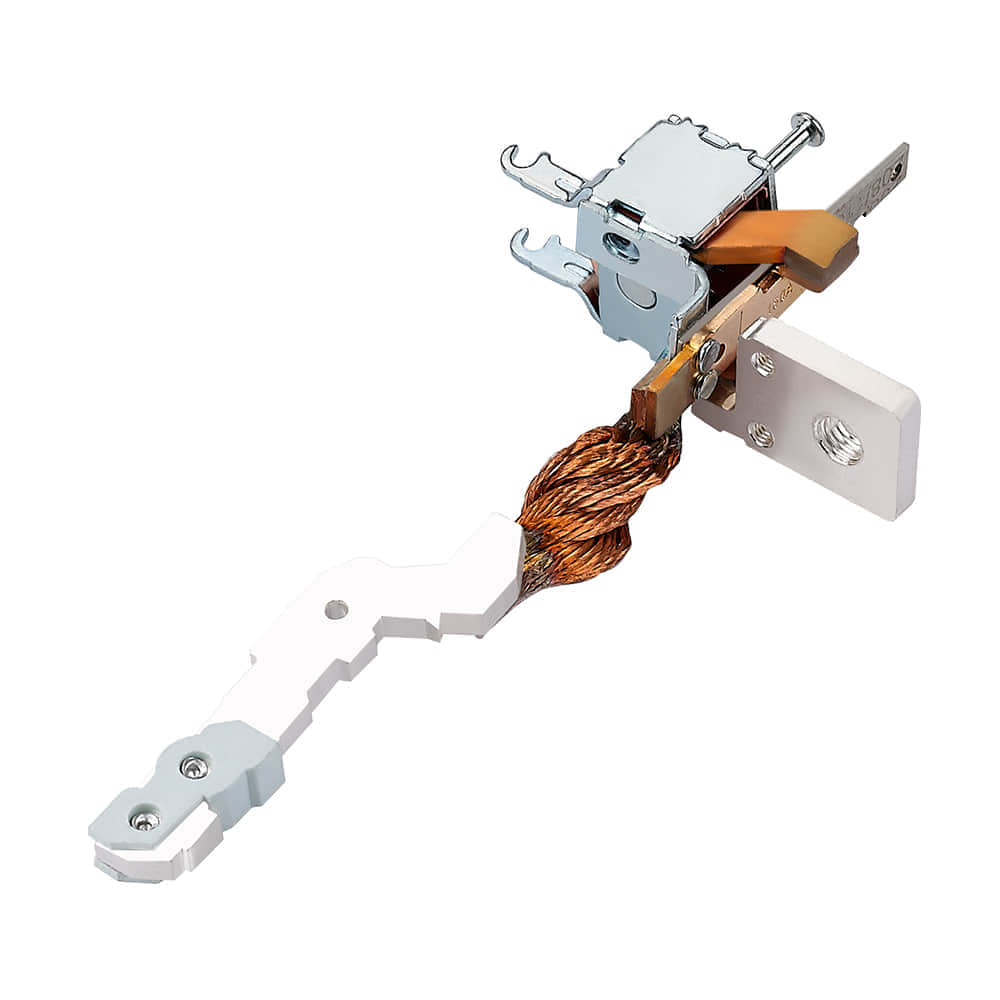

Metal stamping is a manufacturing technique that involves cutting, shaping, and forming metal sheets or coils into various desired shapes and sizes. This process is essential for industries ranging from aerospace to healthcare, as it enables the production of highly precise components with consistency and efficiency. The Core Processes Metal stamping manufacturers employ several core processes: Blanking: This involves cutting the desired shape out of a metal sheet. Precision is paramount, as any deviation can lead to component defects. Piercing: Piercing is the process of creating holes or openings in the metal. This is a critical step for components like brackets and brackets used in various industries. Bending: Bending machines are used to create intricate bends and curves in the metal. This step is crucial for forming parts such as brackets, clips, and connectors. Deep Drawing: Deep drawing involves stretching a metal sheet over a die to create complex, three-dimensional shapes, like the body of a cookware item or an automotive component. Materials Matter Metal stamping manufacturers work with a wide range of materials, including steel, aluminum, copper, and more. The choice of material depends on the intended application, with factors such as strength, conductivity, and corrosion resistance taken into account. Advanced Technology The metal stamping industry has embraced advanced technology to enhance precision and efficiency. Computer Numerical Control (CNC) machines are commonly used, allowing for highly accurate and repeatable processes. Additionally, robotics and automation have streamlined production lines, reducing labor costs and minimizing errors. Quality Control Quality control is of utmost importance in metal stamping. Manufacturers employ rigorous testing and inspection methods to ensure that each stamped component meets strict quality standards. This commitment to quality ensures the reliability and safety of the final products in which these components are used. Applications Across Industries Metal stamping parts find applications in a wide range of industries: Automotive: From chassis components to engine parts, metal stamping plays a pivotal role in the automotive sector, ensuring safety and performance. Electronics: The tiny components in your smartphone or laptop often involve metal stamping. These precise parts are essential for modern electronic devices. Aerospace: Aerospace manufacturers rely on metal stamping for lightweight yet durable components, contributing to the safety and efficiency of aircraft. Medical: In the medical field, metal stamping helps create intricate and sterile components used in everything from surgical instruments to diagnostic equipment. Construction: Building structures and infrastructure projects benefit from metal stamped parts, ensuring stability and longevity. Environmental Considerations In an era of increasing environmental awareness, metal stamping manufacturers are also adopting sustainable practices. Recycling and responsible material sourcing are becoming more prevalent in the industry, reducing its environmental footprint. The Future of Metal Stamping As technology continues to advance, the metal stamping industry will likely see further improvements in precision and efficiency. 3D printing and additive manufacturing may complement traditional metal stamping processes, offering new possibilities for customization and design. Conclusion Metal stamping parts manufacturers are the unsung heroes of modern manufacturing, producing the precision components that enable our technological advances. From transportation to healthcare, their work touches every aspect of our lives. As we move into a future marked by innovation and sustainability, metal stamping manufacturers will continue to evolve, ensuring the reliability and quality of the products we depend on every day.